www.magazine-industry-usa.com

22

'23

Written on Modified on

ANDRITZ TO DELIVER COMPLETE OLD CORRUGATED CONTAINERS LINE TO PAPEL PRENSA, ARGENTINA

Papel Prensa S.A. is a leading Argentinean paper manufacturing company with the country’s highest paper production volume.

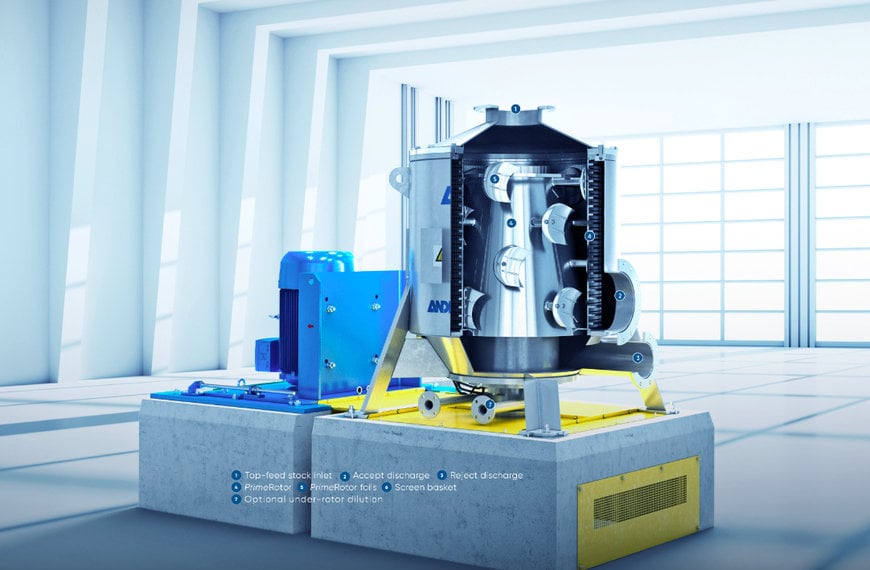

PrimeScreen X for improved energy efficiency, screening performance, and maintainability © ANDRITZ

ANDRITZ has received an order from Papel Prensa S.A. to supply a complete old corrugated containers (OCC) line including a reject handling system to its mill in Buenos Aires, Argentina.

In its initial production phase, the new line will process 180 t/d of local OCC. The line's processing capacity can be easily increased through a minor adjustment to configuration to support the expected rise in pulp demand for the production of corrugated paper. The new line will provide high pulp quality at cost-efficient and resource-saving operation, with the latest technology available.

ANDRITZ’s scope of supply comprises

ANDRITZ has received an order from Papel Prensa S.A. to supply a complete old corrugated containers (OCC) line including a reject handling system to its mill in Buenos Aires, Argentina.

In its initial production phase, the new line will process 180 t/d of local OCC. The line's processing capacity can be easily increased through a minor adjustment to configuration to support the expected rise in pulp demand for the production of corrugated paper. The new line will provide high pulp quality at cost-efficient and resource-saving operation, with the latest technology available.

ANDRITZ’s scope of supply comprises

- the complete LC pulping system with a FibreSolve FSR pulper and an innovative detrashing system to ensure superior slushing of the raw material at minimum fiber loss

- the protection cleaning, fractionation and screening stage including a PrimeScreen X with newly developed PrimeRotor for high screening efficiency at lower power consumption

- an innovative reject handling system featuring a Reject Compactor ReCo to dewater the rejects to the highest possible dry content

- erection supervision, commissioning, start-up, and training

Start-up of the new line is scheduled for 2024.