www.magazine-industry-usa.com

23

'23

Written on Modified on

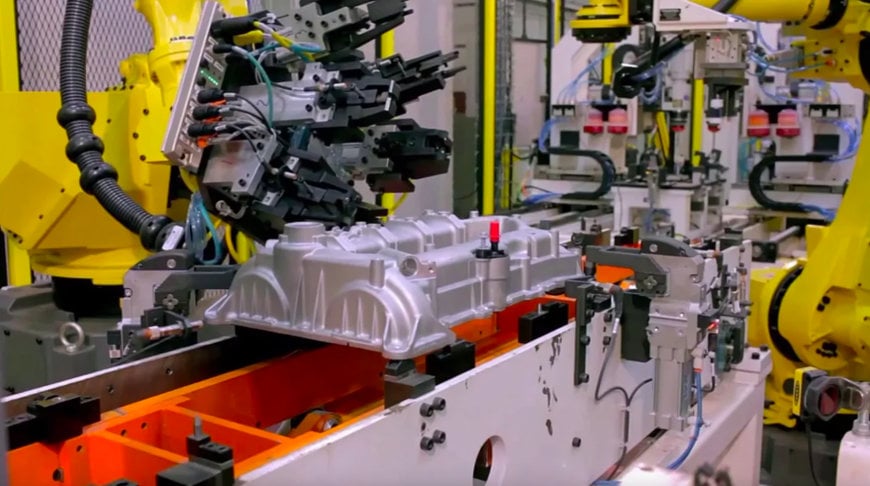

FANUC AMERICA SHOWCASES AUTOMATION SOLUTIONS FOR THE RACING INDUSTRY AT PRI

FANUC America will demonstrate its latest ROBODRILL Plus Vertical Machining Center and CRX Cobots at Performance Racing Industry (PRI), Dec. 7-9 in Indianapolis, booth #5635.

FANUC ROBODRILL Plus Vertical Machining Center

FANUC’s ROBODRILL α-DiB5 Plus vertical machining center comes available in three sizes (small, medium, and large) to accommodate a wide range of precision operations. The ROBODRILL DiB5 Plus provides customers with unrivaled quality and precision features. A compact design with accessibility from all sides enhances overall efficiency for high-speed milling, drilling, and tapping applications.

Powered by the FANUC Plus Series 31i-B5 Control, the ROBODRILL Plus provides unbeatable cycle times for three to five-axis operations. In addition, it offers tool change times as low as 0.7 seconds, and a servo-driven turret capable of handling tools weighing up to 4 kg.

Since FANUC products share common servo and control platforms, the ROBODRILL Plus is easy to learn, operate, and integrate FANUC robots for any automated machine tending application.

At PRI, FANUC’s ROBODRILL Plus will be featured in two automated processes, including:

- High-Speed Impeller Machining: A FANUC ROBODRILL α-D14iB5 Plus will showcase high-efficiency machining of automotive impellers. The ROBODRILL will be equipped with a Tsudakoma RTT-112 for fast five-axis simultaneous operations and automated by the FANUC CRX-5iA cobot.

- High-Efficiency Machining: A FANUC ROBODRILL α-D14iB5 Plus paired with the all-familiar DDR-TSiB will demonstrate high-speed four-axis milling, drilling, and tapping on an aluminum connecting rod. Tended by a FANUC CRX-10iA/L cobot, the ROBODRILL Plus offers customers an easy-to-use mobile automation solution for a wide range of applications.

Easy to Use CRX Cobots

FANUC’s collaborative robots are easy to use and flexible solutions for companies looking to improve productivity and solve labor issues. FANUC’s entire series of CRX collaborative robots are reliable, flexible, and can work for up to eight years without maintenance. Easy-to-use interactive programming allows operators to teach points using hand guidance or a Tablet TP with drag and drop icons.

FANUC’s collaborative robots are easy to use and flexible solutions for companies looking to improve productivity and solve labor issues. FANUC’s entire series of CRX collaborative robots are reliable, flexible, and can work for up to eight years without maintenance. Easy-to-use interactive programming allows operators to teach points using hand guidance or a Tablet TP with drag and drop icons.