www.magazine-industry-usa.com

17

'15

Written on Modified on

DRIVE AND MOTOR SOLUTION CUTS EXTRUDER ENERGY USAGE BY 9%

The prospect of improved energy efficiency, increased operational reliability and lower maintenance costs appeals to any business.

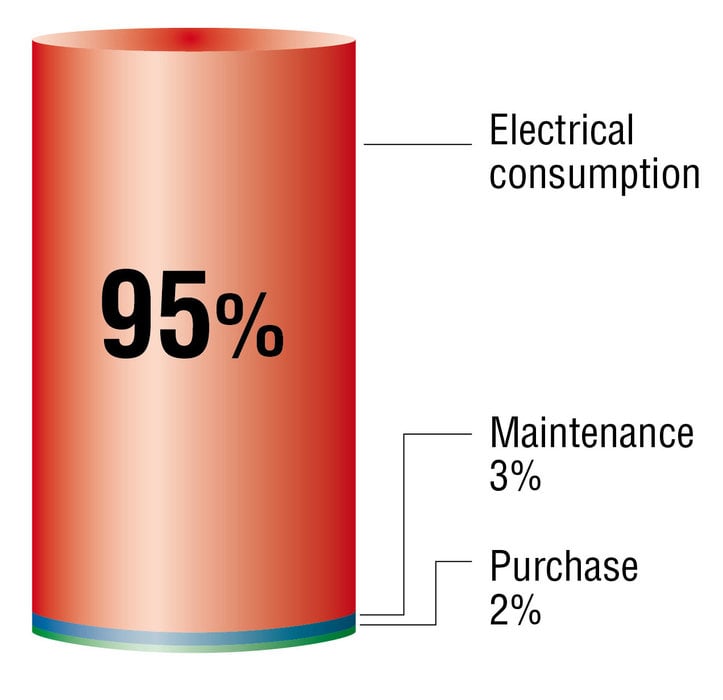

The annual energy savings have been calculated at an average of 9% or 90,000 kWh, which is particularly interesting in the long term, keeping in mind that over 10 years, 95% of the total costs of an electric motor is directly related to the energy consumption.

Stål & Plast A/S, which is located right in the heart of Denmark, manufactures bench tray systems which are used in greenhouses and nurseries worldwide. The raw plates are manufactured at a modern co-extrusion plant operated by three extruder motors, one 175 kW motor and two 71 kW motors. The extruder plant’s three worn-out DC motors were due for extensive reconditioning or alternatively an expensive and time-consuming replacement, as new DC motors would have to be made to order.

As the DC technology is expensive and outdated in terms of energy consumption and moreover associated with high operation and maintenance costs, A/S, Jacob Braa Sørensen, managing director of Stål & Plast, in consultation with Emerson Industrial Automation, decided to upgrade the extruder plant by purchasing highly efficient Dyneo PM motors from Leroy Somer, which are controlled by a Control Techniques Unidrive M700 variable speed drive.

One of the aspects that mattered most to Stål & Plast A/S was that Emerson was the only supplier that could offer to replace the motors and the controls as a total project for which they would assume full responsibility.

The replacement took place in collaboration with the service partners Lindpro as the professional installer and automation provider for the project, and Ølgod Elektro, which routinely handled commissioning and running-in.

Stål & Plast A/S manufactures a broad range of top-quality bench tray systems, which are used in greenhouses and nurseries worldwide. The tray systems are manufactured on a fully automated vacuum forming machine. The company manufactures its raw plates on a modern co-extruder that makes it possible to manufacture the plates in three layers.

For Stål & Plast A/S, the main reason for choosing a motor technology with permanent magnets was, first of all, the long-term energy savings on power consumption but also the higher operating torque, the operational reliability of PM technology and the very low maintenance costs compared with DC technology.

Calculations showed that Stål & Plast could reduce the annual energy consumption of the three motors by an average of 9%. The extruder accounts for 75% of the plant’s total energy costs, of which most is consumed by the extruder motors.

Over a period of 10 years, 95% of the total costs of an electric motor are directly attributable to the energy consumption, whereas the purchase price and the maintenance costs represent as little as 5% of the total costs of the investment when choosing the Dyneo PM motor technology from Emerson.

Since 1984, Stål & Plast A/S has manufactured Ebb/Flow products in high impact polystyrene, which is sold by a worldwide network of distributors. The distributors are typically nursery construction companies that install the tray systems as part of a total project purchased by a nursery.

Over the years, the tray systems have been thoroughly tested against common fertilisers, temperature impact, UV radiation and normal daily wear and tear in a modern greenhouse. This know-how is used to improve and optimise the products on an ongoing basis.

The tray systems are produced on modern fully automated vacuum forming machines that are optimised for the production of Ebb/Flow products. The production plants are primarily operated by robots and monitored by trained staff with years of experience.

The company manufactures its raw plates on a modern co-extruder that makes it possible to manufacture the plates in three layers. As a result, the finished trays can be manufactured in accordance with the customer’s exact requirements and with all the desired characteristics.