www.magazine-industry-usa.com

14

'23

Written on Modified on

Visual Components presents Simulating Automation in the Manufacturing of Windows

Invio Automation used Visual Components’ 3D simulation software to identify and communicate effective automation solutions for a drive-thru window manufacturer.

Sometimes manufacturers have a list of automation projects they would like to explore and implement in their facilities. Prioritizing these projects often requires assessing technical feasibility and risk, calculating return on investment, and communicating the future-state vision and value to senior management and company executives. On other occasions, manufacturers may be confident in how automation could help address their problems, but they are not sure where to begin or how to do it. For companies with limited automation experience or internal engineering capabilities, both scenarios can seem daunting.

This latter situation was one that Invio Automation, an industrial automation systems integrator, encountered recently. Invio’s Factory of the Future Consulting team was commissioned by a building products OEM that assembled windows to help evaluate how to increase throughput while maintaining or reducing overall direct labor.

Invio’s consulting team began its process by partnering with the customer team to develop a long list of potential ideas. From there, the Invio team needed to whittle down the long list of ideas to a small number of potential, highly impactful projects. This meant exploring multiple concepts with the client, evaluating each idea’s ROI, and pitching the shortlist of proposals to business managers. In the past, this process required intensive effort and often utilized tools like PowerPoint to communicate nascent ideas visually. For this project, however, Invio Automation turned to Visual Components’ manufacturing simulation software to accelerate its ideation process.

The resulting proposals were produced in less time, evaluated more rigorously, and garnered a higher level of client support than had been seen in previous projects. This case study explains how that was achieved and how Visual Components software contributed to the success of the undertaking.

Individual sections address:

- Solving complex engineering problems for the largest industrial companies in the world

- Finding solutions for an increase in demand

- Automation and the role of Visual Components

- Benefits of Visual Components in identifying potential automation cases

- Simulating Automation in window manufacturing

Solving complex engineering problems for the largest industrial companies in the world

In many industries, manufacturers are under pressure to improve quality and cut costs. An additional and widespread challenge is labor shortages stemming from high levels of retirement and difficulties in recruitment. For many manufacturers, including the one discussed in this case study, their biggest challenge is satisfying a high level of demand.

Most manufacturers understand automation is a way to tackle these problems. For some, automation means robots and CNC machines. Others are investing in autonomous guided vehicles (AGVs) or autonomous mobile robots (AMRs). And many are looking further into the realm of hyper-automation where all aspects of the business are candidates for improvement.

When manufacturers seek step-change process improvements, they often start by engaging with an industrial automation system integrator. Invio Automation is one of the larger integrators in North America and offers an extensive range of capabilities. AMRs, custom assembly cells, robotic automation, machine vision, and web handling applications are just some of their areas of expertise.

Invio works with clients in industries such as medical devices, renewables, automotive, and building products. A common problem for many clients across all these environments is that they either do not know what automation could do for them or they are unsure of where to start on the process of automating their existing, and often highly manual, operations. For these businesses, Invio offers its Factory of the Future Consulting service.

The Factory of the Future process starts with an on-site workshop to review the client’s existing manufacturing operations. Subject-matter experts and others from Invio Automation convene at the customer’s facility to identify opportunities. After the on-site workshop, Invio engineers develop 3D concepts and simulations. Through a high degree of collaboration with the client over a period of just a few weeks, a list of initial target projects emerges, and the basis of an ongoing relationship is formed.

Finding solutions for an increase in demand

Manufacturing windows for the construction industry is big business. According to a report published by Research and Markets, the global windows market is expected to grow by ~9% CAGR through the end of the decade.

These windows are engineered for repeated opening, rapid operation, and hostile environments. Many have security features, and some are power-operated. Customers demand a wide range of shapes and sizes and a high level of customization. Consequently, producers making these types of windows have deployed very little automation to date.

Invio Automation was commissioned by a window manufacturer to lead a consulting engagement focused on automating processes that were historically highly manual. This manufacturer’s processes have remained largely unchanged over the last decade and consisted of manual fabrication steps, manual assembly, unstructured material handling, and more. Facing increasing demand for their products, leadership was very aware that things had to change to keep up with the growing demand. For Invio and the customer team, the primary goal of the study was to identify and define projects that would enable a substantial increase in output without adding labor. Quality improvements and other indirect cost savings, while not sought explicitly, would of course be very welcome.

Automation and the role of Visual Components

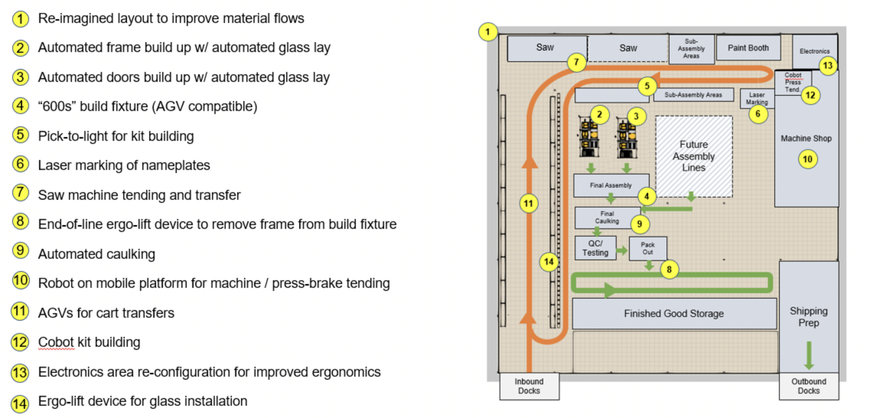

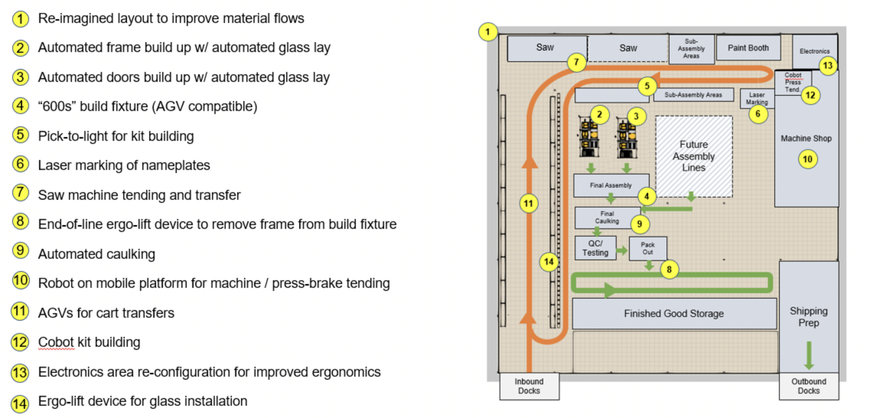

Invio Automation started the process by reviewing the customer’s current practices during an on-site workshop at the factory. The Factory of the Future team worked with the client to identify 14 potential automation and process improvement opportunities. In the subsequent investigations and discussions, the collection of 14 projects was narrowed down to three concepts that had a high probability of increasing throughput.

Each concept was investigated carefully, exploring options, identifying the types of equipment to use in window manufacturing, and the expected benefits. Invio used Visual Components software to help them with these activities.

A leader in 3D manufacturing simulation, Visual Components monitors trends in automation and robotics to better provide manufacturers with tools for exploring production line concepts, cells, and workflows. While often used for manufacturing process optimization, it’s also a tool for evaluating the output to be expected from new production equipment, layouts, and workflows. It permits the assessment of factors like robot reach and cycle time, identification of production constraints, and evaluation of potential throughput rates, given varying production schedules.

A particularly important aspect of Visual Components software for integrators like Invio Automation is the ability to produce a 3D concept rendering of a proposed arrangement or layout. This helps a team developing automation concepts explain their ideas, and so get better quality feedback and direction from the client.

In their “Factory of the Future Consulting” study, Invio used Visual Components software to create automated work cells, conceptualize automation solutions, and present these to their client.

Benefits of Visual Components in identifying potential automation cases

At the time this consulting study began, Invio Automation was new to Visual Components factory simulation software. Previously, the Invio team relied on a combination of 3D CAD and PowerPoint to communicate ideas and iterate with their clients. For this study, however, Invio’s engineering team to see what could be gained from using Visual Components simulation software.

The team saw benefits in three areas:

In many industries, manufacturers are under pressure to improve quality and cut costs. An additional and widespread challenge is labor shortages stemming from high levels of retirement and difficulties in recruitment. For many manufacturers, including the one discussed in this case study, their biggest challenge is satisfying a high level of demand.

Most manufacturers understand automation is a way to tackle these problems. For some, automation means robots and CNC machines. Others are investing in autonomous guided vehicles (AGVs) or autonomous mobile robots (AMRs). And many are looking further into the realm of hyper-automation where all aspects of the business are candidates for improvement.

When manufacturers seek step-change process improvements, they often start by engaging with an industrial automation system integrator. Invio Automation is one of the larger integrators in North America and offers an extensive range of capabilities. AMRs, custom assembly cells, robotic automation, machine vision, and web handling applications are just some of their areas of expertise.

Invio works with clients in industries such as medical devices, renewables, automotive, and building products. A common problem for many clients across all these environments is that they either do not know what automation could do for them or they are unsure of where to start on the process of automating their existing, and often highly manual, operations. For these businesses, Invio offers its Factory of the Future Consulting service.

The Factory of the Future process starts with an on-site workshop to review the client’s existing manufacturing operations. Subject-matter experts and others from Invio Automation convene at the customer’s facility to identify opportunities. After the on-site workshop, Invio engineers develop 3D concepts and simulations. Through a high degree of collaboration with the client over a period of just a few weeks, a list of initial target projects emerges, and the basis of an ongoing relationship is formed.

Finding solutions for an increase in demand

Manufacturing windows for the construction industry is big business. According to a report published by Research and Markets, the global windows market is expected to grow by ~9% CAGR through the end of the decade.

These windows are engineered for repeated opening, rapid operation, and hostile environments. Many have security features, and some are power-operated. Customers demand a wide range of shapes and sizes and a high level of customization. Consequently, producers making these types of windows have deployed very little automation to date.

Invio Automation was commissioned by a window manufacturer to lead a consulting engagement focused on automating processes that were historically highly manual. This manufacturer’s processes have remained largely unchanged over the last decade and consisted of manual fabrication steps, manual assembly, unstructured material handling, and more. Facing increasing demand for their products, leadership was very aware that things had to change to keep up with the growing demand. For Invio and the customer team, the primary goal of the study was to identify and define projects that would enable a substantial increase in output without adding labor. Quality improvements and other indirect cost savings, while not sought explicitly, would of course be very welcome.

Automation and the role of Visual Components

Invio Automation started the process by reviewing the customer’s current practices during an on-site workshop at the factory. The Factory of the Future team worked with the client to identify 14 potential automation and process improvement opportunities. In the subsequent investigations and discussions, the collection of 14 projects was narrowed down to three concepts that had a high probability of increasing throughput.

Each concept was investigated carefully, exploring options, identifying the types of equipment to use in window manufacturing, and the expected benefits. Invio used Visual Components software to help them with these activities.

A leader in 3D manufacturing simulation, Visual Components monitors trends in automation and robotics to better provide manufacturers with tools for exploring production line concepts, cells, and workflows. While often used for manufacturing process optimization, it’s also a tool for evaluating the output to be expected from new production equipment, layouts, and workflows. It permits the assessment of factors like robot reach and cycle time, identification of production constraints, and evaluation of potential throughput rates, given varying production schedules.

A particularly important aspect of Visual Components software for integrators like Invio Automation is the ability to produce a 3D concept rendering of a proposed arrangement or layout. This helps a team developing automation concepts explain their ideas, and so get better quality feedback and direction from the client.

In their “Factory of the Future Consulting” study, Invio used Visual Components software to create automated work cells, conceptualize automation solutions, and present these to their client.

Benefits of Visual Components in identifying potential automation cases

At the time this consulting study began, Invio Automation was new to Visual Components factory simulation software. Previously, the Invio team relied on a combination of 3D CAD and PowerPoint to communicate ideas and iterate with their clients. For this study, however, Invio’s engineering team to see what could be gained from using Visual Components simulation software.

The team saw benefits in three areas:

- Speed

- Customer communication

- Quality of concepts developed

In terms of speed, the Invio team estimates that by using Visual Components software, their workflows were sped up three times compared to how iterations were previously done. They also observed a noticeable improvement in customer perception and understanding of the concepts presented.

As to the quality of the concepts, the team felt Visual Components software was well suited to different levels of automation. Said Ben Graham of Invio Automation,

“It was so flexible… Whether we were in the concept of this fully automated cell, [or] looking at some material flow for a semi-automated cell, we found the tool very powerful and valuable as we tried to determine what was best for the customer. The flexibility of the tool was tremendous and enabled our team to explore various levels of automation”

Simulating automation in window manufacturing

Invio’s consulting process concludes with a formal report presented to the client. The report Invio Automation produced for the window manufacturer addressed:

As to the quality of the concepts, the team felt Visual Components software was well suited to different levels of automation. Said Ben Graham of Invio Automation,

“It was so flexible… Whether we were in the concept of this fully automated cell, [or] looking at some material flow for a semi-automated cell, we found the tool very powerful and valuable as we tried to determine what was best for the customer. The flexibility of the tool was tremendous and enabled our team to explore various levels of automation”

Simulating automation in window manufacturing

Invio’s consulting process concludes with a formal report presented to the client. The report Invio Automation produced for the window manufacturer addressed:

- Potential automation projects

- High-level estimates of costs and benefits

- Hardware/equipment requirements