www.magazine-industry-usa.com

02

'23

Written on Modified on

TRUMPF reports breakthrough in industrializing SWIR VCSELs above 1300nm

TRUMPF targets SWIR VCSEL manufacturing in state-of-the-art, high-volume production process, outstanding results of robustness and performance of long wavelength VCSELs, revolutionary VCSEL technology that enables new sensing application fields such as under-OLED sensors.

TRUMPF Photonic Components, a global leader in VCSEL and photodiode solutions, is industrializing the production of SWIR VCSELs above 1300 nm to support high volume applications such as in smartphones in under-OLED applications. The company demonstrates outstanding results regarding the efficiency of infrared laser components with long wavelengths beyond 1300 nm on an industrial-grade manufacturing level.

This takes TRUMPF one step further towards mass production of indium-phosphide-based (InP) VCSELs in the range from 1300 nm to 2000 nm. “At TRUMPF we are working hard to mature this revolutionary production process and to implement standardization, which would further develop this outstanding technology into a cost-attractive solution. We aim to bring the first products to the high-volume market in 2025,” said Berthold Schmidt, CEO at TRUMPF Photonic Components. By developing the new industrial production platform, TRUMPF is expanding its current portfolio of Gallium arsenide- (GaAs-) based VCSELs in the 760 nm to 1300 nm range for NIR applications.

The new platform is more flexible in the longer wavelength spectrum than are GaAs, but it still provides the same benefits as compact, robust and economical light sources. “The groundwork for the successful implementation of long-wavelength VCSELs in high volumes has been laid. But we also know that it is still a way to go, and major production equipment investments have to be made before ramping up mass production”, said Schmidt.

VCSELs to conquer new application fields

A broad application field can be revolutionized by the industrialization of long-wavelength VCSELs, as the SWIR VCSELs can be used in applications with higher output power while remaining eye-safe compared to shorter-wavelength VCSELs. The long wavelength solution is not susceptible to disturbing light such as sunlight in a broader wavelength regime.

One popular example from the mass markets of smartphone and consumer electronics devices, is under-OLED applications. The InP-based VCSELs can be easily put below these OLED displays, without disturbing other functionalities and with the benefit of higher eye-safety standards. OLED displays are a huge application field for long wavelength sensor solutions.

“In future we expect high volume projects not only in the fields of consumer sensing, but automotive LiDAR, data communication applications for longer reach, medical applications such as spectroscopy applications, as well as photonic integrated circuits (PICs), and quantum photonic integrated circuits (QPICs). The related demands enable the SWIR VCSEL technology to make a breakthrough in mass production”, said Schmidt.

Exceptional test results

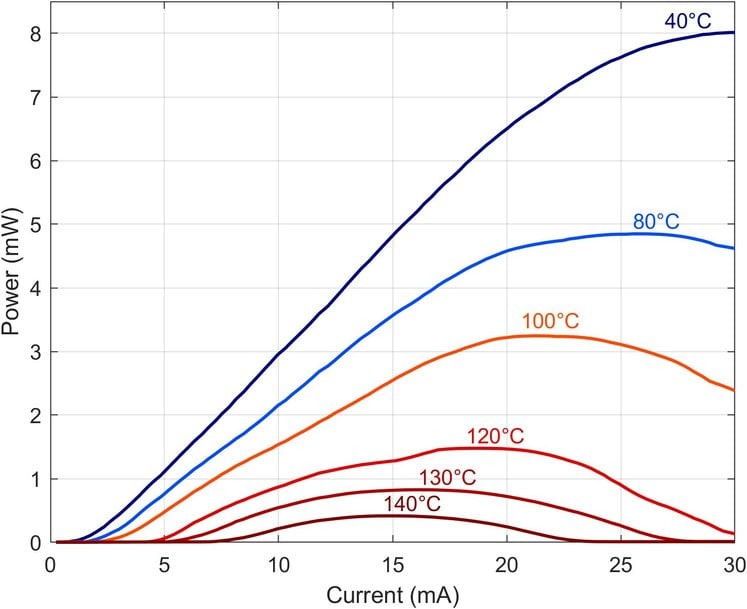

TRUMPF presents results showing VCSEL laser performance up to 140°C at ~1390 nm wavelength. The technology used for fabrication is scalable for mass production and the emission wavelength can be tuned between 1300 nm to 2000 nm, resulting in a wide range of applications. Recent results show good reproducible behavior and excellent temperature performance.

“I’m proud of my team, as it’s their achievement that we can present exceptional results in the performance and robustness of these devices. We are confident that the highly efficient, long wavelength VCSELs can be produced at high yield to support cost-effective solutions”, said Schmidt.

Visit TRUMPF Photonic Components at Photonics West 2023 at booth 539.

www.trumpf.com