www.magazine-industry-usa.com

20

'22

Written on Modified on

FROM VISION TO REALITY. FPT INDUSTRIAL REVEALS THE DIRECTION OF ITS ENERGY TRANSITION STRATEGY AT IAA TRANSPORTATION 2022

FPT Industrial’s multi-energy approach towards sustainable on-road propulsion was revealed at IAA Transportation, the world’s leading trade show for the transportation industry as well as the most important platform for innovations and technologies in the transport market, held in Hannover (Germany) from 19 to 25 September 2022.

At its stand (Hall 21/stand 34), FPT Industrial showcased exciting world premieres and the path the company is taking to reduce the environmental impact of road transport. The Brand also shared the vital role a leading powertrain manufacturer must play to ensure the continuity of key businesses together with a guided, smooth and accessible path for the energy transition.

INTERNAL COMBUSTION ENGINE AREA – THE JOURNEY GOES ON

This section of the stand showcased a full line of ICEs, from light to heavy applications. This means that FPT Industrial continues to believe and invest in internal combustion engines through range extensions and continuous improvement, state-of-the-art technologies and competitive solutions, all designed to meet new customer requirements. This course of action implies a sustainable and focused approach, where FPT Industrial’s leadership and know-how in natural gas for on-road applications will be a springboard to realizing a technology transfer to meet the net-zero carbon emissions goal.

NEW XC13 – THE CONCEPT TAKES SHAPE

The Brand’s new XC13, unveiled at IAA 2022, represents the embodiment of the Cursor X concept – the multi-energy, modular, multi-application, and mindful engine. Unmistakable with the flaming red X imprinted on the engine head, the XC13 is FPT Industrial’s first multi-fuel single base engine. From diesel to natural gas – including biomethane – hydrogen, and renewable fuels, the base engine has been designed with multiple versions to offer maximum component standardization and easy integration into the final product.

The XC13 features unique DNA for on-road multi-applications, is immediately compatible with a range of different market requirements and emission regulations, with limited impact on vehicle installation.

The new XC13 engine positions itself as a primary contributor to achieving short and mid-term fleet CO2 emissions targets. A major step in the ICE decarbonization path, the XC13 guarantees lower emissions, together with world-beating performance. The diesel version delivers best-in-class performance up to 600 hp and 2,850 Nm, resulting in +5% power and 14% torque compared to the current Cursor 13 model. The methane version delivers up to 520 hp and 2,500 Nm resulting in +13% power and +25% torque compared to the current Cursor 13 Natural Gas. CO2 emissions reductions stand at 9% for the diesel unit and 10% for the methane model, but the latter can achieve net-zero CO2 emissions when fueled by biomethane. The natural gas version offers diesel-like performance. Designed for the future, and for future emissions challenges, the XC13 will be ready for Euro VII with simple upgrades.

Braking power also achieves best-in-class performance, with a +29% increase on the diesel version (up to 530kW @ 2300 rpm) and a stunning +300% on the methane model (up to 245kW @ 2300 rpm). Last but not least, both versions are significantly lighter: -10% (100 kg) for diesel and -10% (80 kg) for the methane model. This weight reduction is achieved thanks to the Compacted Graphite Iron casting for the cylinder head and block, reducing wall thickness while improving thermo-mechanical strength.

In short, this revolutionary and ultra-versatile engine has all it takes to be a serious contributor in the sustainable transport sector. Economic and environmental sustainability is improved by enhanced combustion efficiency, thanks to a new fuel injection system and higher peak cylinder pressure, reduced friction, down speeding and new divided-flow turbo – a unique concept for the Diesel version – smart auxiliary equipment management, and by FPT Industrial’s proprietary software for integrated combustion and ATS control.

The 152 kW F1C and the N67 NG for commercial vehicles complete the Internal Combustion Engine line-up presented by FPT Industrial at IAA Transportation 2022.

ePOWERTRAIN AREA – ZERO EMISSIONS SOLUTIONS NOW

In this area, FPT Industrial clarified its current and future position as zero emissions solution provider with primary focus on eAxles, Central Drive, Modular Battery Packs and Battery Management Systems. This position will be achieved with the intervention of two different yet connected factors. Firstly, the imminent opening of the new ePlant for ePowertrain production, as well as continuing to create disruptive solutions, through its DNA as a game changer and an Open Innovation approach, acting with an agile mindset and also partnering with smaller companies in the electric mobility sector. Through this approach, FPT Industrial aims to become a fully fledged ePowertrain system manufacturer.

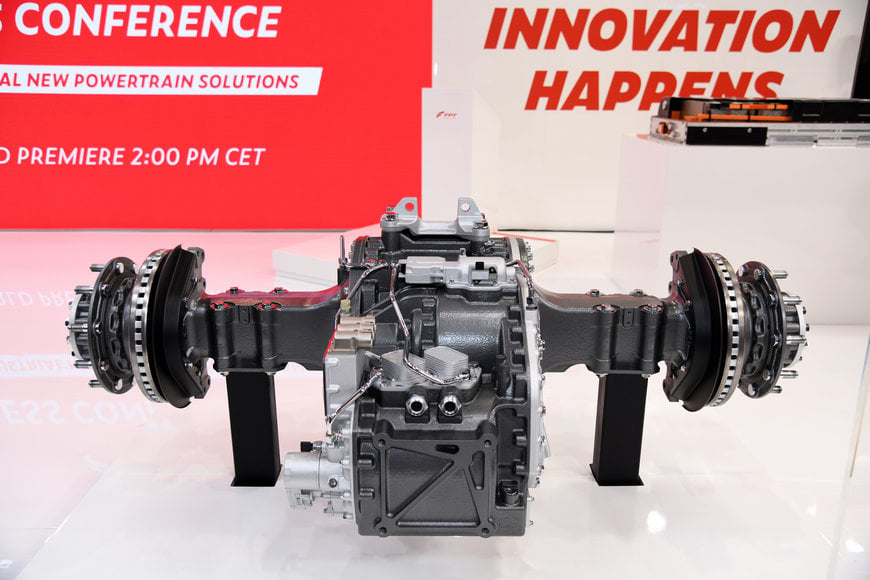

SECOND-GENERATION eAXLE FOR 4X2/6x2 MCVS AND 6X4 HCVS – THE FUTURE IS COMING

With the unveiling of the eAX375-R, FPT Industrial has clarified its strategy for the electrification path of medium and heavy commercial vehicles. The new eAxle will suit medium-duty 4x2/6x2 and heavy-duty 6x4 vehicles, delivering high performance and efficiency, thanks to its two-speed gear set. The second-generation eAxle is designed to be fully scalable, to accommodate specific customer requirements, and to broaden the range of applications. Thanks to this new addition, the eDriveline range also includes light and heavy versions, providing solutions for electrification for all vans, light, medium, and heavy trucks and buses from 3.5 to 44 tonnes – and beyond.

CENTRAL DRIVE FOR LCVs – INTEGRATING ELECTRIC DRIVE INTO CONVENTIONAL VEHICLES

The electric Central Drive 140 is a complete, compact solution for integrating electric drive systems into existing conventional light commercial vehicles and minibuses (Gross Vehicle Weight up to 8 tonnes). FPT Industrial’s engineering team has designed a lean and robust central drive, in order to guarantee easy integration with existing platforms and optimized space during installation for integration of battery packs. The eCD 140 delivers peak power of up to 140 kW and axle torque of up to 1.6 kNm; it is designed for rear-wheel-drive applications, and offers outstanding efficiency (>92%) and durability (up to 350 km). It incorporates a parking lock system for safety, and is easily adaptable for hybrid solutions. Visitors to the show were able to see the eCD at the IVECO booth.

BATTERY PACKS FOR BUSES – PASSENGER TRANSPORT GOES GREEN

Created in partnership with Microvast, FPT Industrial’s battery packs have been developed for LCVs, minibuses and bus applications, with Microvast taking care of the modules and cells, and FPT Industrial creating the housing and handling complete integration.

At IAA 2022, FPT Industrial showcased the new 69 kWh battery for bus applications for the very first time, a product which offers high energy density in a versatile solution, thanks to its modular pack system. It has been developed in partnership with Microvast, a market leader in ultra-fast charging and long-life battery power systems for industrial applications.

CUSTOMER SERVICE – FPT INDUSTRIAL STANDS ALONGSIDE ITS CUSTOMERS AT ALL TIMES

The Brand’s stand at IAA Transportation 2022 featured an area dedicated to Customer Service, an important factor when dealing with solutions for on-road mobility. This corner offered a clear vision of the pillars on which FPT Industrial has built its renowned customer service reputation: reliability, protection, and uptime.

The common trait of the Services that the Brand offers is supporting customers in the easiest and most efficient manner, delivering the best customer experience. Through these Services, customers can rely on FPT Industrial’s on-road engines and spend their time on the road, with minimal worries.

“The evolution of a carbon-based economy into a new, sustainable circular economy is perhaps the greatest technological challenge of the industrial era,” adds Sylvain Blaise, President of the Iveco Group Powertrain Business Unit. “And as producers of propulsion systems we are at the core of it. Our outstanding display of innovation and sustainable technology here in Hannover demonstrate our full commitment to reaching the ‘net zero carbon’ goal by 2040 and being a key technology enabler for our customers and partners.”

“The Multi-energy approach is the cornerstone of our product strategy,” says Pierpaolo Biffali, Vice President Product Engineering, FPT Industrial. “Internal combustion engine still represents one of many sustainable solutions we have in our toolkit, together with our complete ePowertrain offering including battery and electrified driveline.”