www.magazine-industry-usa.com

19

'22

Written on Modified on

The octoplant software solution sets the standard for securing factory automation and optimizing the connection between OT and IT

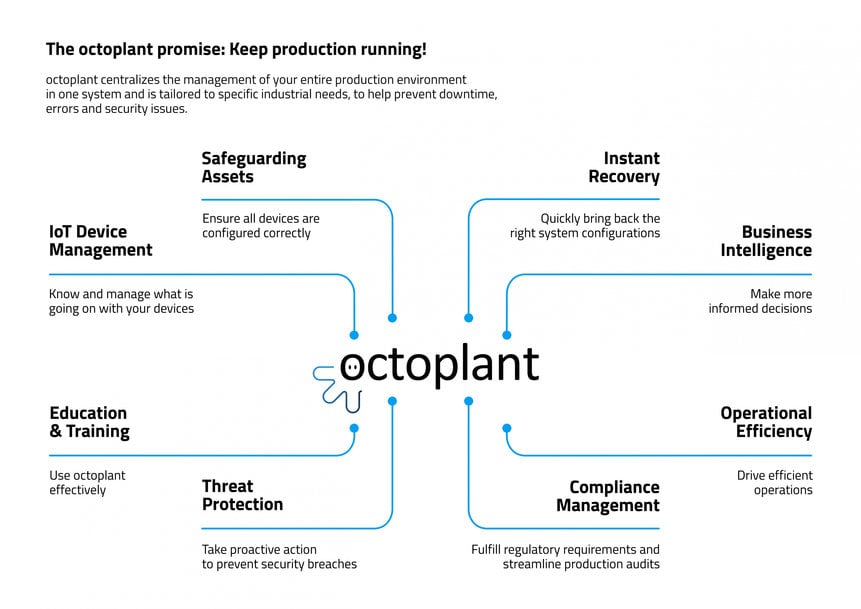

The new software platform helps reduce production downtime and provides optimal protection against data loss through a vendor-independent backup and cyber security strategy.

AUVESY-MDT, one of the world's market and technology leaders for data management in highly automated industrial enterprises, is proud to introduce: octoplant, the next level of development of the versiondog and AutoSave solution, currently used at more than 2500 companies, including many of the world’s leading automotive, food, water, life science and mining companies. octoplant is a new data management platform that provides a vendor-independent and comprehensive view of all automation backup processes involving OT and IT. Users are protected against production downtime, data loss and also experience significantly increased cyber security.

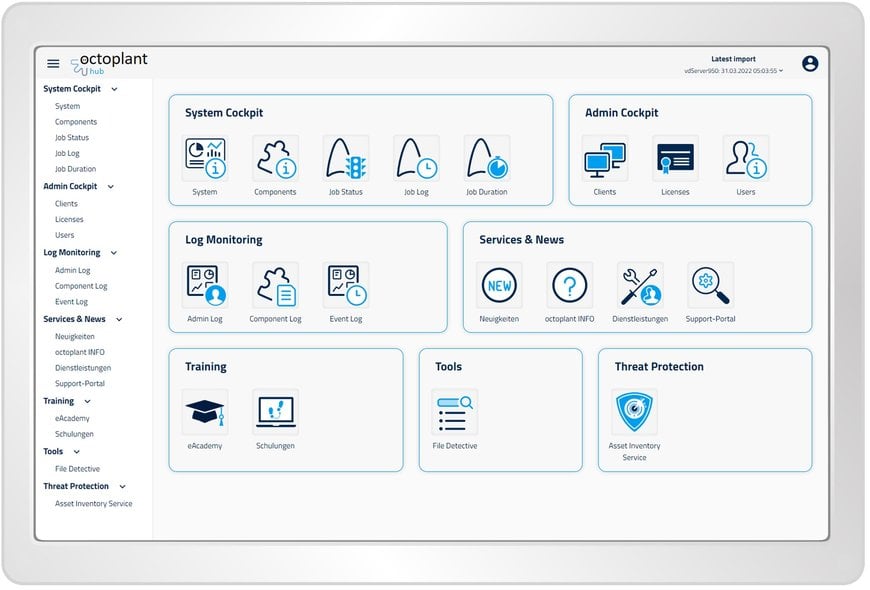

Due to constantly growing plant floor complexity, manufacturing companies are being increasingly threatened by production downtimes, which can cost millions in downtime and lost profits. octoplant provides maximum protection against this danger. Consisting of eight function sets, octoplant is tailored to different industrial needs and uses dashboards to display the various statuses of the plant clearly and precisely.

With this software, production managers know where programs and configurations are stored and how up to date they are at the touch of a button. In regard to production data, they are able to take quick and decisive action in the event of system failure or when production comes to a standstill by restarting production and restoring the previous settings. This is not only possible when the shutdown is due to common equipment malfunctions, but also if the plant is the victim of a cyber-attack.

octoplant displays the current and correct status of all machine programming as well as the version history of all changes with detailed visibility into program differences through tabular and graphical reports. This makes it easy to see which changes were made, when and why. With automatic program backups, a previous version can be restored in just a few clicks, saving time, and avoiding product errors. Automatic backups can apply to a single device or the entire plant, even if it consists of several hundred or even several thousand devices and sensors, and hardware and software components.

octoplant is now available as a subscription model at www.auvesy-mdt.com/en/octoplant.

"octoplant is a milestone in the development of digital asset management solutions for industrial companies," explains Dr. Tim Weckerle, Group CEO at AUVESY-MDT. "It is the first product that we have jointly developed and brought onto the market since we merged to form AUVESY-MDT. This solution provides us with the best foundation to further expand our leadership position as a partner for the industry, providing maximum reliability, minimum downtime as well as the highest quality and safety standards.”

"octoplant also stands out because this software has the greatest compatibility in a market comparison, both across manufacturers and devices," explains Stefan Jesse, Group COO at AUVESY-MDT. "Comparable solutions only cover individual machines or partial aspects of a plant, such as PLC, SCADA and HMI or the programming of robotics. This is exactly where octoplant comes into play as it provides the highest transparency on the function and safety status of all plant elements. As the perfect link between OT and IT, octoplant enables companies to advance to a new and forward-looking level in the key areas of business intelligence and cyber security.”