www.magazine-industry-usa.com

20

'20

Written on Modified on

Try it before you buy it: SMC technologies now available in Automation Studio

SMC and Famic Technologies offer the convenient and efficient virtual assembly of pneumatic systems.

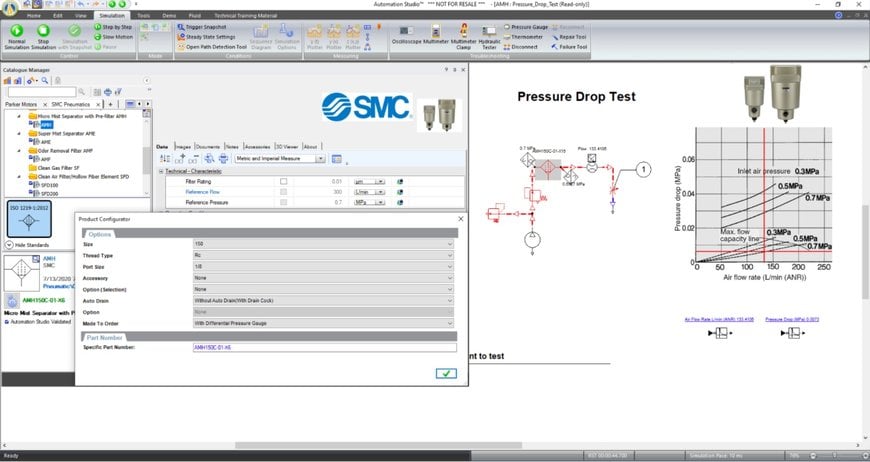

Designing and planning pneumatic circuits has never been easier: SMC has made its own product library available for this purpose for use with the design and simulation software Automation Studio from Famic Technologies. The two companies are working together to support planners and machinery builders with their combined knowledge in the areas of simulation and application. Users of Automation Studio can now create and simulate pneumatic circuits using SMC components.

Application expertise meets simulation knowledge

“As a developer of high-performance systems and services in the fields of software engineering and industrial automation, Famic Technologies is the ideal partner for Industry 4.0 applications,” says Christian Ziegler, Manager Digital Business Development at SMC. “In an era of increasing digitalization, the benefits of the virtual planning and simulation of circuits are obvious. It enables users to personally compile technologies that are suitable for them and to test individual solutions. For that reason, we are combining our technological knowledge with the simulation expertise of Famic Technologies.” If the pneumatic circuit is suitable and works well, the designer can directly export the relevant components as a parts list. “This saves time and money for users, as they no longer need to laboriously search through catalogs for the parts,” explains Richard Gagné, Quality Manager at Famic Technologies. “It also makes the work of SMC’s pneumatics experts easier, as they know that the

parts lists compiled in this way have already been tested in the virtual environment.”

The complete integration of all technology modules in the Automation Studio software—from pneumatics to the human-machine interface—is particularly useful, as it enables the virtual assembly, animation, and validation of entire systems. Richard Gagné further states: “Simulation also offers additional benefits. For example, virtual circuit diagrams can be subjected to extensive start-up tests in a safe environment. This provides designers with unique insights into the function of their planned systems.”

An inventor’s paradise: Engineers can now make full use of the SMC pneumatic library in Automation StudioTM, enabling them to plan the right pneumatic circuit for the job – and integrate it into complete systems.

A quicker and more convenient route to finished products

The integration of the SMC pneumatics library into Automation Studio catalogues makes the planning and realization of complete systems even easier—and applications even more efficient and productive. Ziegler is delighted with the successful collaboration: “Working alongside Famic Technologies, we have created a genuine win-win-win situation. We benefit from the increased visibility of our products, Famic extends its range of technologies, and designers can now access our extensive portfolio of high-performance and reliable pneumatics solutions.” Richard Gagné is also convinced of the merits of the partnership: “Virtual planning and design plays a key role nowadays in the realization of new machinery and equipment. Our collaboration with SMC shows the potential that still exists in this area.”

www.smc.com