www.magazine-industry-usa.com

09

'20

Written on Modified on

Future-proof power, data and signal transmission

Connectivity for Future Technologies / Han® S: Connectors for efficient energy storage / ix Industrial portfolio is being successively expanded / SPE partner network continues to grow.

Globalisation, demographic change and climate issues - these megatrends are having a major impact on industry. Tomorrow’s manufacturing must also be more strongly converted to energy efficiency and sustainability. HARTING is providing the connectivity to master these challenges - Connectivity for Future Technologies! In the field of automation, the three trends of digital twin, connectivity and modularity will drive further development significantly. Machines and systems will become more autonomous - and will increasingly be making more independent decisions in future.

Modularisation in mechanical engineering entails many advantages, not only for manufacturers but also for users. Thanks to modularisation, they benefit from cost-optimised products that are precisely tailored to their requirements, while transparently designed at the same time. HARTING’s Han-Modular® series is providing expedient solutions for all interfaces required in modern control, drive, HMI and communication technology for production systems. They are making power, data and signal transmission future-proof. Thanks to such solutions, modularisation can be further advanced without functional restrictions.

Existing systems can be easily upgradable

The Han® 300 A module is precisely one such modularisation driver, which HARTING has launched this year and is showcasing on the occasion of the "electronica" and "SPS" digital trade fairs. It is reverse compatible with the proven 200 A module and can therefore also be plugged onto this module (whereby the lower rated power is then available). As a result, existing systems can be easily upgraded. The new module is designed in such a way that both direct connections to a busbar and installations in slide-in systems are readily possible. The market requirement for the module to be touch-proof on both the socket and pin sides is also met.

Integration of 10 Gbit/s Ethernet in modular connectors

The demand for higher transmission rates is driving the continuous development of data interfaces. This not only applies to office area, but also to the industrial arena, where the advantages of modular interfaces are especially relevant. All common bus systems can be easily adapted, including Profibus, Profinet, CAN, Ethernet Cat. 5, Cat. 6A and Cat. 7A.

Thanks to the M12 module, there is now an additional option of integrating 0 Gbit/s Ethernet into modular connectors. The module enables significant space savings: two D- or X-coded M12 connectors fit into a single module. By comparison with conventional RJ45 solutions, the M12 system is more robust and offers even greater operational reliability.

Interface for shielded cables

The new Han® Shielded Power Module offers three power contacts and one PE contact for connecting typical three-phase loads. In addition, there are two signal contacts for temperature monitoring, brakes or similar elements, as well as a generously dimensioned shield transition, which enables EMC-compliant connection of the cable shield directly to the module. This provides an alternative to the fixed wiring of shielded power cables, while at the same time allowing such connections to be made in a common housing alongside other modules of the Han-Modular® series.

Shielded power module for frequency converters

HARTING has tested the module in the EMC laboratory in practical applications: The EMC properties of the shielding transition in the Han® Shielded Power Module are entirely sufficient for typical drive applications, such as frequency-controlled three-phase motors or other loads. It allows the pluggable design of shielded power cables, is easy to handle, while enabling direct shield connection to the module. This results in reduced installation times for machines and systems, in the factory or at the end customer.

Moreover, the series is supplemented by an EMC-protected module for signal transmission. With a generously dimension shield transition and an additional 360° shielding plate, this module not only ensures good shielding, but also enables impressive transmission options in a compact space: up to 27 shielded D-Sub contacts up to 4A / 32V can be plugged in. Under the name Han® Shielded Modul Basic, this new product will enable users in mechanical engineering and robotics, for example, to easily and cost efficiently integrate shielded transmission into modular connectors.

Han® S: Connectors for the efficient construction of energy storage systems

In addition to new products for mechanical engineering, HARTING will also be presenting new products for the energy market at SPS 2020: powerful, easy-to-handle connectors enable efficient construction of energy storage systems. With Han® S, HARTING is now offering for the first time a connector solution for front mounting of energy storage modules. The new series ensures optimum safety levels, as the design meets all technical requirements and the latest UL 4128 standard for stationary energy storage systems.

Han® S: Connectors for efficient energy storage.

The single-pole connectors can transmit rated currents up to 200 A with a voltage of 1500 V. Han S® ensures safe installations thanks to the touch-proof contacts with different connection types (M8 screw or busbar). The locking status is always visible and easy to check. Moreover, the HARTING product is vibration-proof and available in two different colours: red (+) and black (-). The coding is mechanical, thereby preventing incorrect connections of polarity.

Ethernet communication: ix Industrial® portfolio to be successively expanded

With the clearly stated mission to offer a smaller, more robust and powerful alternative to conventional Ethernet connectors, HARTING has entered the Ethernet connector market with the ix Industrial®. In order to meet the relevant demands, the ix Industrial® portfolio will be successively expanded and extended by all the necessary variants to achieve these aims and objectives. This includes straight and angled versions, various locking systems and IP protection classes. No matter where Ethernet needs to be installed in the device in a space-saving and reliable way, ix Industrial® is the interface of the future.

SPE partner network growing

The ecosystem of various companies and suppliers revolving around SPE technology and the IEC 63171-6 standard initiated by HARTING is growing rapidly. The SPE Industrial Partner Network e.V. currently comprises some 37 members, and their number is increasing every week. With the T1 Industrial Interface HARTING is providing the connectivity foundation for SPE connections in future IIoT networks. SPE is taking Ethernet all the way through to the field level. Only one protocol, a uniform infrastructure and reduced implementation times are just a few of the advantages of single-pair cabling.

The SPE Pioneer Summit 2020 took place on 3 and 4 November. Top-class keynote speakers and panel discussions clearly showed that now is the right time to invest in SPE technology. Subsequently, 18 Network experts took the seminar participants on a guided tour of all the details and aspects of the SPE ecosystem.

Frank Welzel, Head of Global Product Management HARTING Electronics and Chairman of the SPE Industrial Partner Network e.V., was also at hand and announced the important cooperation with the AMA.

New definition of high speed connections

The reduction of assembly time is one of the most important savings potentials in automation plant construction. HARTING has also thought one step ahead for users in the area of existing, set interface concepts and with the RJ Industrial® Multifeature 10 Gbit, is offering an industrial grade RJ45 with an integrated wire cutter.

The solution offers 25% faster assembly thanks to the integrated miniature knives. These automatically shorten and cut the individual wires during assembly and thereby provide very simple and error-free field assembly with practical strain relief. Cat. 6A performances for all PoE classes and the variable cable outlet in 5 outlet directions ensure faster assembly with increased handling safety and robustness. This represents reliable solution delivering savings potentials for optimising existing and new networks.

har-modular®

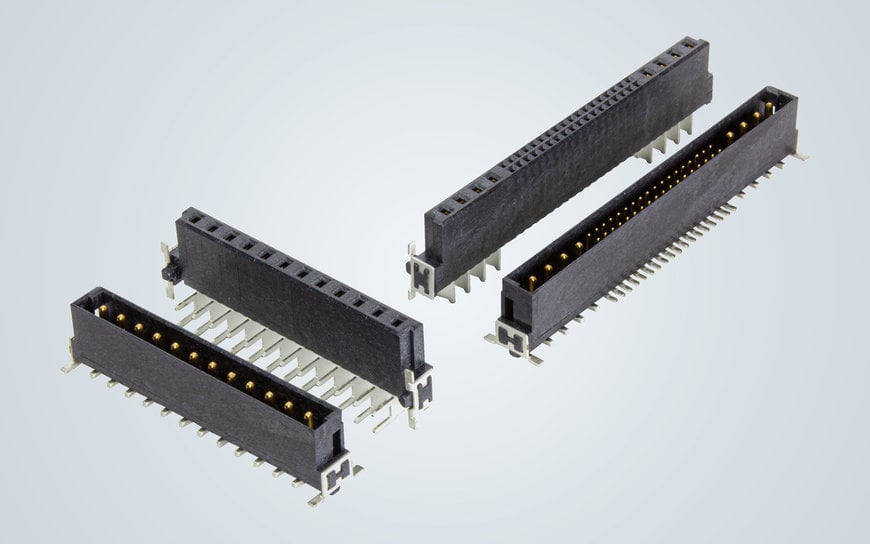

In the autumn of 2020, the PCB Connectivity sector will be taking centre stage. With the introduction of the har-modular®, HARTING is presenting an absolute world first for the connection of PCBs. A modular concept based on the reliable DIN 41612 strips, but modularly configurable as from batch size 1. Modularity is thereby completely redefined for design-in devices. Thanks to an online configurator, it is possible to select from a trillion possible combinations and thereby always arrive at the ideal solution, even for small series and prototypes. This represents an enormous simplification of work and time savings on the way to the finished product. True to the claim of CREATE YOUR OWN, users can choose from any number of contacts for power, signals and data. Where several connectors used to be necessary, har-modular® combines all the desired lifelines in one single connection.

The flexible and self-configurable board solution har-modular® is setting new standards.

har-flex® Hybrid&Power

The flexible portfolio revolving around the miniaturised PCB connector har-flex® in 1.27mm pitch is extended by power variants for even greater scope of freedom and also includes hybrid solutions combining power and signals. This combination eliminates the use of separate power and signal connectors on the board. Both lifelines are thereby combined in a single space-saving connection.

Just like the new har-flex® hybrid solutions for miniaturised power and data transmission in the device.

The power variants also reduce the space required for power transmission as opposed to conventional, previous solutions. Here, users have often taken the path of conducting power via several signal contacts connected in parallel. Naturally, this results in a higher number of contacts, which accordingly require more space. Thanks to har-flex® Power, this power can now be transmitted over approximately half the required surface area. Consequently, har-flex® variants are once again making vital contributions to the miniaturization megatrend.

www.harting.com