www.magazine-industry-usa.com

29

'13

Written on Modified on

MAXXDRIVE Industrial Gearing from NORD DRIVESYSTEMS - At work in the Swiss Alps

Located in the Swiss Alps, Industrial Gearing from NORD DRIVESYSTEMS is an integral part of the pumped storage hydroelectric power station expansion entitled “Linthal 2015 project”.

Fig 2 - NORD MAXXDRIVE SK12407 drives the lower conveyor belt.

Pumped-storage hydroelectricity:

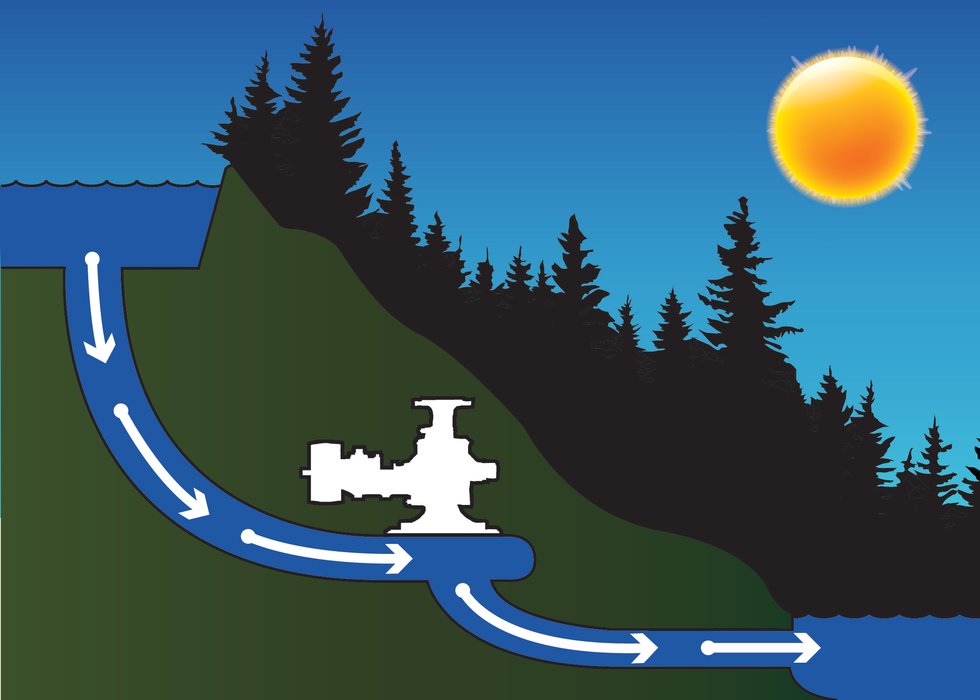

PSH is a type of hydroelectric power generation used by some power plants for load balancing. The method stores energy in the form of potential energy of water, pumped from a lower elevation reservoir to a higher elevation. Low-cost off-peak electric power is used to run the pumps. During periods of high electrical demand, the stored water is released through turbines to produce electric power.

Reversible turbine/generator assemblies act as pump and turbine and the height difference between the two bodies of water, natural or artificial reservoirs, is critical.

Fig 3 - Daytime: water flows downhill thru turbine, producing electricity

Fig 4 - Nighttime: water is pumped uphill to reservoir for tomorrow’s use

At an altitude of about 5,600 ft. and some 2000 ft. inside the mountain, the heart of this gigantic expansion project is being created with huge excavated chambers that will house underground pump stations.

Every day about 28,248 ft³ of rock has been removed from the mountain and in total almost 86,000,000 ft³ has been excavated to form the chambers.

Drive systems for conveyors

NORD Large Industrial gear units (350 HP each) drive the conveyor belts, the first moving 500 tons of material per hour over a distance of about 850 ft. with an extreme incline of 45 degrees and a height difference of 600 ft. down to the crushing plant while the second conveyor belt transports the crushed material up to the gravel plant, where it is stored.

Fig 5 – Conveyor driven by NORD DRIVESYSTEMS

The NORD Large Industrial gear units have been developed according to the well-proven UNICASE™ housing design in which all the bearings and seals are contained within a single casting. The UNICASE™ concept was pioneered by NORD in 1980 and features the highest levels of precision, rigidity and strength by eliminating splits and bolt-on covers. There are no separations in the housing which are subjected to torque and radial loads. The UNICASE™ principle enables a more compact design due to the staggered arrangement of the shafts and also allows for the use of larger roller bearings which along with optimized geometries and precise shaft alignment result in long operating life.

Customer-oriented drive solution

"We sell customer benefits - not just products. NORD DRIVESYSTEMS offer a comprehensive service package that includes commissioning and maintenance training, so that the customer knows what to look out for. We offer more than just drive components; rather, we provide complete and functioning system solutions. We tailor our drive solutions to each individual customer” states Guido Eigenmann, Manager of NORD DRIVESYSTEMS AG, Switzerland.

Ernst Kuster, head of maintenance and responsible for conveyor systems at the "Linthal 2015" expansion project, relies on NORD products and services. Ernst’s expectations are continuously exceeded and states: "The communication and cooperation with NORD DRIVESYSTEMS is particularly positive for me. All of our requirements were met. What is also remarkable is NORD’s determination to supply as promised. Delivery was met in weeks and on time. With other suppliers, much longer lead times are not unusual. We are very satisfied. NORD DRIVESYSTEMS provides a very good cost-benefit ratio, excellent advice and support, on-schedule delivery and last-but-not-least, NORD delivers high performance products built of very good quality".