www.magazine-industry-usa.com

07

'20

Written on Modified on

Contactless Handling of Small Parts in the Semiconductor Industry (Chips & Dies)

Gentle, maintenance-free, and clean room compatible handling with ultrasound

Challenges in processing dies

Technical progress and the demand for ever smaller and more powerful processors always lead to demanding requirements. New techniques, such as stacking very thin chips, are needed to enable the manufacture of innovative products. Especially the properties of these thin wafers and chips pose an additional challenge in handling. The materials are flexible, fragile, and wavy, and often also have specially treated surfaces (e.g. with adhesive).

Conventional handling systems often have problems, for example particle contamination in air bearings caused by the air turbulence of compressed air (e.g. Bernoulli grippers). Other systems without air supply, e.g. vacuum grippers, can leave traces such as marks or scratches on the substrate during handling. With the help of the patented ultrasonic bearing from ZS-Handling, substrates can float evenly on an air film generated by vibrations and therefore be held without contact during handling. Through a combination of negative pressure and ultrasound, attracting and repulsive forces act simultaneously on the workpiece, thus keeping it at a distance even when gripping from above.

How does the ultrasonic technology work?

The ultrasonic movement of the so-called sonotrode creates a supporting gas film (air or process gas) between the sonotrode surface and the substrate. The substrate floats on the resulting gas film at distances of 10 - 150 μm, depending on the application. In special cases, higher hovering heights can also be achieved. By using buoyancy forces due to vacuum, handling from above is also possible. In this way, any mechanical surface contact is avoided.

The physics of the ultrasonic bearing results from the flow dynamics and not from acoustic principles. The gas pressure in the gap between the workpiece and the vibrating surface increases due to the cyclic compression and decompression of the thin gas film. It is therefore necessary to realize a uniform oscillation pattern in order to generate constant floating forces over the entire sonotrode. The vibrations are not transmitted into the substrates and do not lead to any impairment of the substrate material.

Advantages

With the repulsive forces of the ultrasonic bearing, the substrate can be moved without any friction even at very high speeds. In combination with vacuum, attractive forces can be applied simultaneously, which allows handling from above. In addition, flexible materials can be "smoothed" without contact by this technique, i.e. they can be kept in an even, centered position.

For very small components (up to approx. 12x12 mm), the self-centering effect is effective when the gripper tip is precisely adjusted, which means that no side stops are required even for very precise positioning.

The force profile of ZS-Handling handling systems is similar to that of a conventional air bearing, but no compressed air supply is required. This means, for example, that in a clean room environment the laminar air flow - unlike with Bernoulli grippers - is not disturbed by high flow velocities and no particles can penetrate through external air or via pipes. Also, in new production lines the costs for the compressed air supply can be saved.

By avoiding surface contact and without dynamic turbulence in the ambient gas, no damage, micro-scratches, micro-cracks, or contamination can damage the substrate. Handling on machined or coated surfaces is possible without contact, allowing more degrees of freedom in process and machine design. During handling, a high level of flatness of the substrate is achieved as well.

The systems can be used in all atmospheric processes and in up to 20% partial vacuum processes. This requires fewer resources, such as energy or compressed air, than a standard air bearing. This has a positive effect on the energy and cost balance for the handling systems of ZS-Handling.

Exemplary requirements of a use case:

In a clean room environment of ISO 6, dies of different sizes (10x10 mm, 5x5 mm and 5x12 mm) are to be separated from a cut wafer (ø 300 mm) attached to a sawing foil with a contactless gripper. After that, the dies should be placed for the subsequent bonding process.

The solution of ZS-Handling

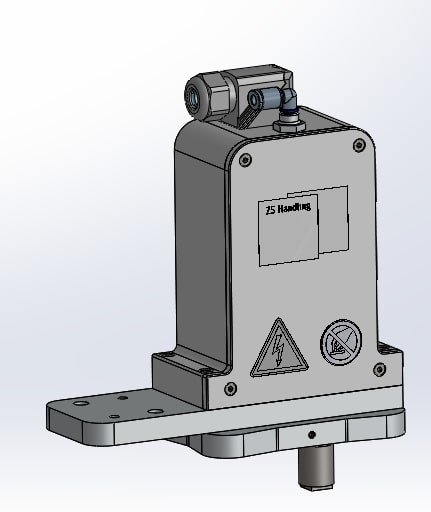

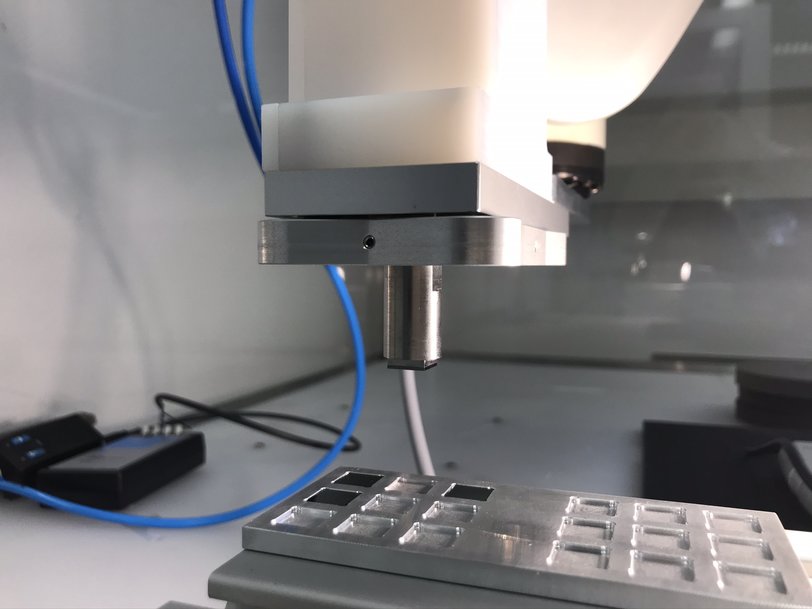

ZS-Handling's solution includes the MicroLevi Gripper with different gripper tips for the different sizes, which can be easily exchanged using a collet chuck. With ultrasound and vacuum at the same time, the die can be gripped from above and held and swiveled without contact. Due to the self-centering effect at the gripper tip, the die can be gripped and placed down precisely even at rapid accelerations of over 2g. In order to achieve an optimal centering effect, the gripper tip must be adapted exactly to the format of the die, therefore three different gripper tips are necessary for this application. The gripper can be connected to any robot or axis system by an adaptable flange. Gripper and housing are made of anodized aluminum, the tip of the gripper is made of titanium.

In the application described here, the dies to be separated are pushed upwards by pins under the wafer to reduce the adhesive force on the adhesive film and to facilitate contact-free separation. The die lifted in this way is picked up by the gripper tip without contact and moved to the next process step at high speed, where it can be placed easily and precisely by switching off the vacuum.

Summary

The entire process flow when handling dies takes place fully automatically. With the help of the ultrasonic oscillations, the die is kept in a centered position on the evenly generated air film, so that scratches or any other contact are avoided. In addition, the laminar air flow in the clean room is not impaired by turbulence, thus preventing the transfer of particles.