www.magazine-industry-usa.com

15

'13

Written on Modified on

IM-6600: the IM Series Extends its Field of Applications.

By drastically reducing measurement times, Keyence's IM Series Image Dimension Measurement System has revolutionised full-part inspection. Now with a twice as large field of view (200 × 100 mm) and new illumination options, it can handle larger and more complex targets.

A broad range to cover a maximum of applications.

The IM-6600 controller can be used with four different head units — the IM-6015/IM-6025 (general-purpose models), the IM-6140 (high-precision model, 0.1 µm repetition accuracy) and the all-new IM-6120 (200 mm wide-field model). The IM-6120 features a 200x100mm stage yet still has a remarkably small footprint.

Four types of illumination are now available — backlighting, epi-illumination (for measuring non-through dimensions), ring epi-illumination (for measuring shiny targets or tapered surfaces such as conic sections) and grazing illumination (for measuring targets with uneven surfaces or contours that are hard to delineate due to the diffusion of light).

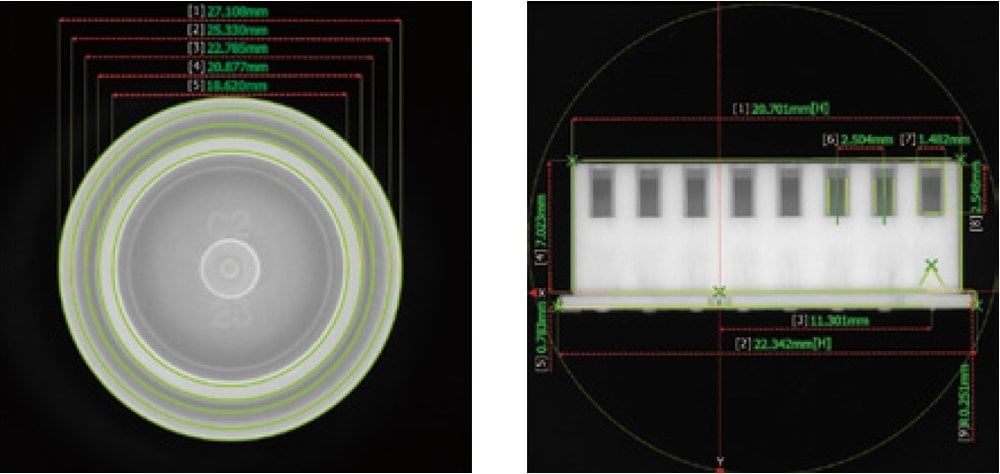

Plastic cap/Mouldedcapacitor.

Ring epi-illumination makes measuring non-through dimensions on bottle caps and other targets with raised surfaces possible. This high-intensity ring of white LED light is cast onto the circumference of the lens. The ring is divided into four parts that are individually turned on and off to obtain the sharpest image. These settings are retained for each specific target to be measured.

Statistical processing of data has also been improved with a new application that extracts measurement data so that it can be imported into conventional spreadsheet software. Users can choose from a set of document templates and customise each layout with a logo or other visual element. The trend graph/histogram function allows on-site analysis of production trends and variations and can help to reduce rejection rates.