www.magazine-industry-usa.com

27

'13

Written on Modified on

Power'Control: Control and Supervision of High-Performance Thermal Energy Pools

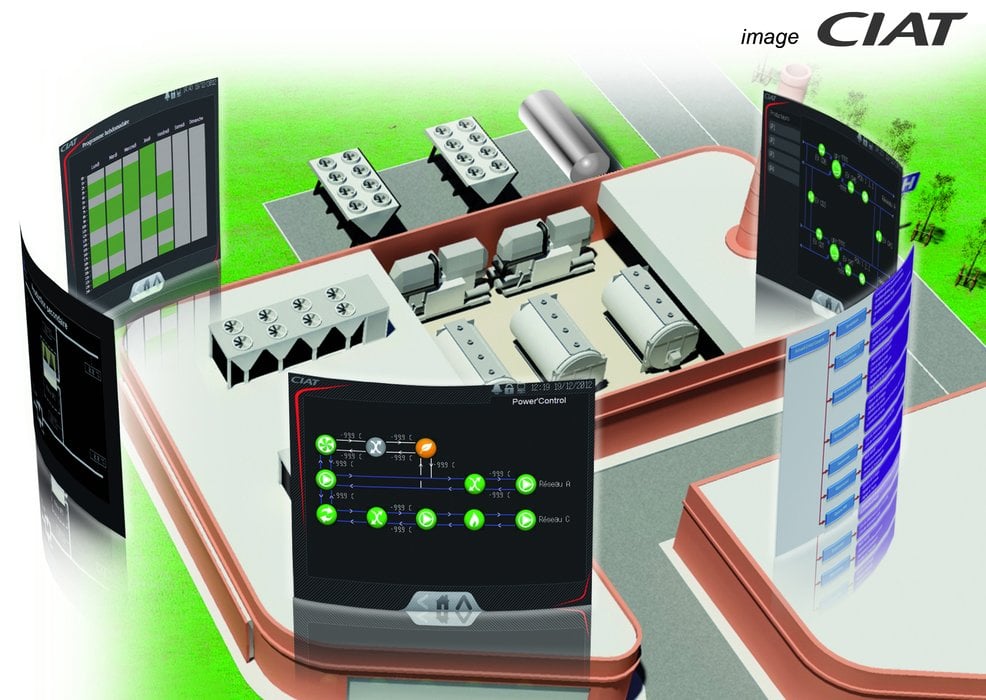

Power'Control is the name of CIAT's specialised control and supervision tool for your entire energy production system. It is part of CIAT's unique hot and cold thermal Energy pool package and guarantees high levels of performance in all situations. Power'Control takes into account the needs specifically defined for each application and defines, in real time, the right production strategies, the best assignment of tasks and the correct allocation of equipment. It autonomously controls systems of chillers or heat pumps, dry coolers, pumps and other ancillary hydraulic equipment and ensures the most efficient modes of production. Depending on the system combination and the type of application, it improves efficiency by 15 to 30%. Power'Control is designed for applications in tertiary environments, shopping centres, hospitals, hotels and industrial refrigeration systems.

Power'Control manages all water chillers, heat pumps and transfer and regulation peripherals, from the primary loop down to the supply manifolds on your distribution networks. As the main control interface, Power'Control allows you to program daily and seasonal schedules, configure setpoints, choose from among various strategies and manage equipment starting, alternation and backup orders. It also reports events (faults, alarms) and serves as a local and remote supervision tool. All operating parameters are displayed as curves and tables and are accessible for remote monitoring, such as via a Web interface. Key information can also be sent to a BMS.

In addition to protecting equipment and ensuring that changes in needs are quickly met, Power'Control's purpose is to improve your thermal system's energy efficiency. It optimises the cascading of chillers and heat pumps as well as the speeds of dry coolers for the condenser circuits of thermodynamic machines based on the loading rate and climate conditions. Power'Control also maximises the use of free cooling according to setpoints configured on the networks. It recovers heat energy from thermodynamic machines for use in primary or third-party networks (heating, preparation of domestic hot water, etc.) and matches production output to actual demand.

Power'Control thus can increase the energy efficiency of Energy pools by as much as 30%.

Power'Control can control up to eight water chillers or heat pumps as well as four dry coolers (up to eight with water-to-water machines) and three plate heat exchanger water loops. It also manages single and double pumps, controls both motorised two-way valves and three-way valves and logs readings from temperature and pressure sensors as well as flowmeters and counters.

Power'Control's many features include a 10" graphic touch screen, an intuitive Touch to Go interface, mimic diagrams that display the status of the system and its components, three access levels (read-only, operator, manufacturer), programming of individual network starting times (automatic summary), and control of the ancillary transfer equipment on the primary production loop.

Power'Control is also a predictive and curative maintenance support tool. It reports alarms, events and faults and feeds back a wide range of data such as equipment usage rates, heat balances, operating deviations, operating times and number of starts.