www.magazine-industry-usa.com

11

'13

Written on Modified on

New Kennametal Brisbane Office Spotlights Full-Spectrum Wear Solutions for Australia and Region

Kennametal Inc., a world leader in providing innovative wear-resistant products and application engineering, is pleased to announce its new facility in Yatala near Brisbane, Australia, dedicated to providing the latest in wear solutions for Australia and the Asian region. The address is 22 Computer Road, Yatala, Queensland, Australia 4207, and the phone number is 61.7.3801.5844.

“The global demand for minerals, commodities, and other mined products continues to grow, and Australia and the South Asia region will play a significant role,” says George Boxsell, regional product manager. “Kennametal is equally well-positioned to supply any number of productivity-enhancing solutions to numerous wear applications, particularly in extreme environments.”

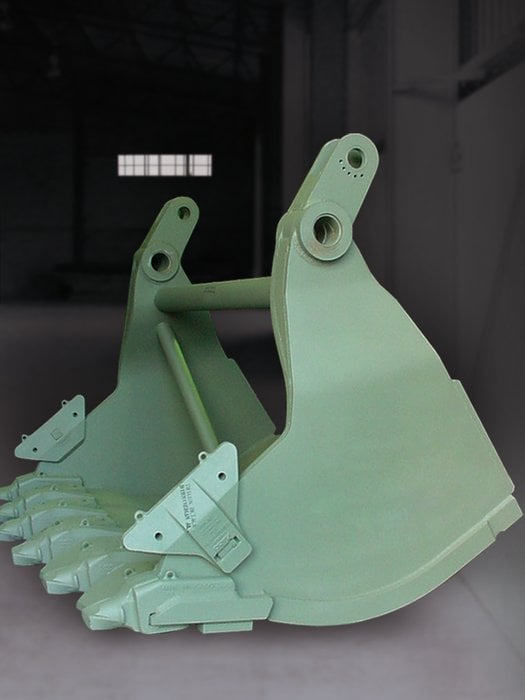

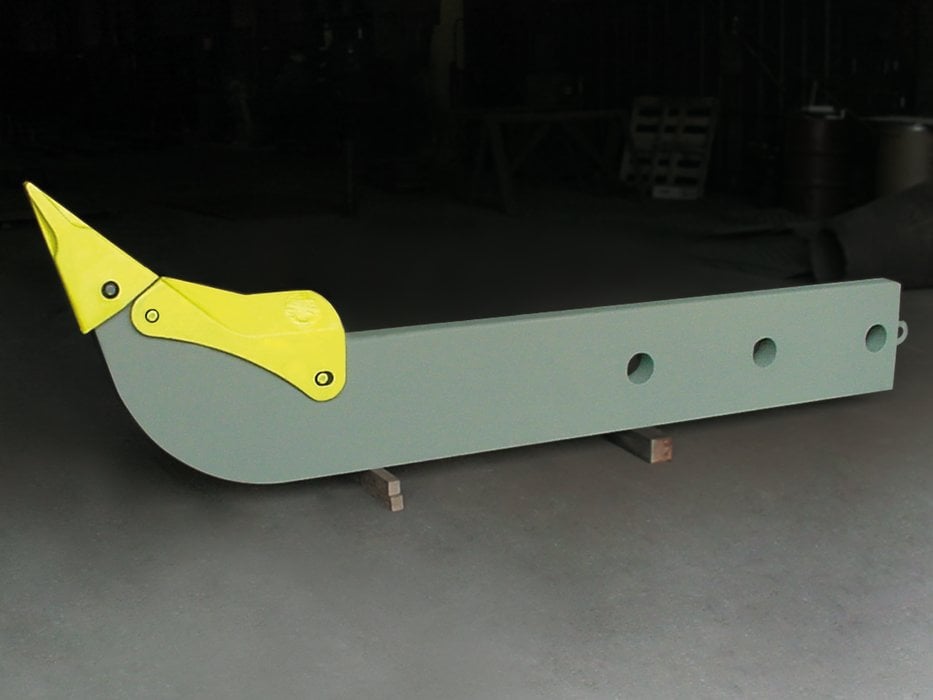

The most extreme jobs – quarrying, mining, earth moving, heavy industry – chew up wear components regularly, raising the costs of doing business. Kennametal’s Tricon family of products, including Dura-Plus™, the next generation of abrasion-resistant alloy steel, is often an effective response.

“This is proprietary alloy steel chemistry that combines hardness, toughness, formability, and weldability unachievable in any other material,” Boxsell says. “Shovels, excavators, buckets, dump truck trays, chutes, hoppers, cutting edges, and other wear components in extreme mining environments are natural fits for this new technology.”

Dura-Plus™ chemistry and processing achieves full hardness throughout the plate, eliminating the “soft middle” found in conventional abrasion-resistant materials. Extremely low sulfur content and fine grain structure yields superior impact resistance while also providing excellent weldability under field conditions. Long performance life and lower maintenance costs for end users are the results.

Dura-Plus™ is available in thicknesses up to 20 mm, widths up to 3 meters (120 inches), and lengths up to 7.3 meters (288 inches) for such high-impact applications as hoppers, crushers, feeders, transfer chutes, shovels, dozers, truck beds, buckets, and discharge sites in surface mining.

Other answers for miners in Kennametal’s Tricon lineup include Tri-Braze™, through-hardened alloy steel for the toughest abrasion and impact applications; Super C™, a chromium-carbide overlay wear-resistant plate with a mild steel base for weldability; Super X™ induction-hardened pins developed specifically for extreme heat and wear situations, and Prime Arc™ welding consumables for efficient field welding and hard surfacing.

Many Capabilities In-House

In addition, the fully operational 2,000 square meter Kennametal facility offers such related services for customers as CAD design, plasma arc and flame cutting, welding and other fabrication services, including press brake forming, drilling, plate rolling, and painting.

“This new facility is an outstanding combination of best-in-class wear materials and the application, design, and fabrication expertise to get products to customers under critical deadlines,” Boxsell adds. “Customers increase their uptime, maximize their productivity, and supply more product to their customers. For the products and solutions that make that possible, Kennametal is your one-stop shop.”

For more information, visit www.kennametal.com.