Sales start for GEA's T.VIS® control top with IO-Link technology on July 1, 2020

The degree of automation in production plants in the food, dairy and beverage industry is constantly increasing. This also increases the demand for intelligent field devices. Sooner or later this leads to a confusing multitude of interfaces with different mechanical and electrical characteristics. In general, the solution to this challenge is called IO-Link and GEA's T.VIS® control top are now available with this technology.

IO-Link provides customers with a standardized solution that simplifies installation and offers extended diagnostic and parameterization capabilities.

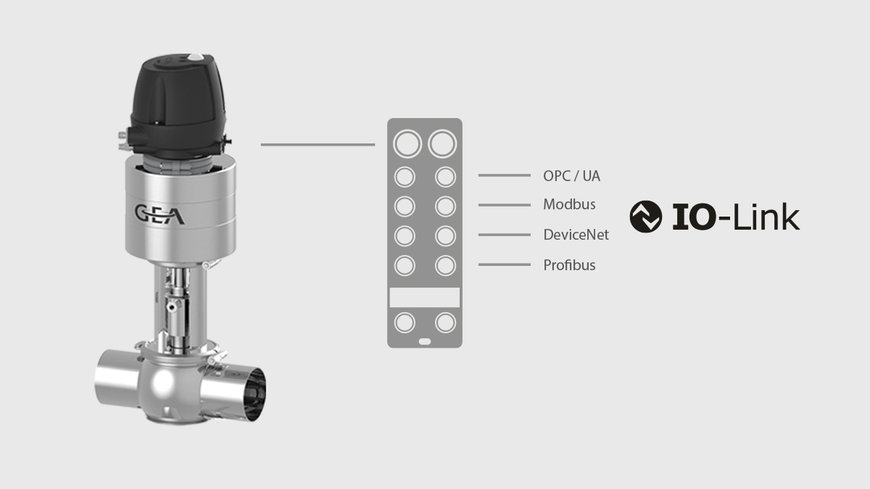

In addition to the 24 Volt, AS-i and DeviceNet communication types already available in the T.VIS® range, the IO-Link technology will now enable GEA valves to make the step into the industrial 4.0 world. IO-Link provides customers with a standardized solution that simplifies installation and offers extended diagnostic and parameterization capabilities.

Access real-time data with the T.VIS® control top program for GEA valves

The T.VIS® control top range for GEA valves offers significant efficiency benefits in the design and operation of food, dairy and beverage production and processing plants. Real-time diagnosis of data and direct access to sensor parameters, especially during valve setup and maintenance, improve the handling and operability of the valve unit. Problems can be anticipated before they escalate. The technology also enables greater plant effectiveness, identification of performance trends and reduction of downtime.

What distinguishes the IO-Link technology?

With the T.VIS® control top with IO-Link technology GEA presents the consistent further development of the previous connection technology for sensors and control tops of the latest generation. IO-Link is the first globally standardized IO technology (IEC 61131-9) for communicating with sensors and also control tops down to the field level. The powerful point-to-point communication is based on the long-known 3-wire sensor and control top connection without any additional requirements on the cable material.

An IO-Link system consists of an IO-Link master and one or more IO-Link devices. The IO-Link master represents the interface to the higher-level control level (PLC) and controls the entire communication with the connected IO-Link devices. This makes the system an intelligent solution at the field level.

The advantages of IO-Link at a glance:

- IO-Link makes sensors and control tops capable of communication

- Process data are exchanged digitally with high signal quality

- Components can be parameterized centrally

- Diagnostic information is transferred from the valve to the controller and can thus be visualized in the operating system.

- Standardized and considerably simplified installation

- IO-Link is fieldbus-independent and can be integrated into all fieldbuses worldwide.