www.magazine-industry-usa.com

18

'20

Written on Modified on

Specialized in packaging machines for confectionery and baked goods: The new DRT 25C from Leuze

The primary and secondary packaging of confectionery and baked goods can be challenging: The new DRT 25C dynamic reference diffuse sensor from Leuze solves precisely this problem in an innovative and reliable way: with a one-of-a-kind reference technology and three light spots.

Leuze's detection expert – the DRT 25C – reliably meets the high requirements of packaging machines for confectionery and baked goods with innovative reference technology.

Sensors must continuously and reliably detect a wide range of products and films on the conveyor belts of primary and secondary packaging machines for confectionery and baked goods (HFFS, FS, Thermoform, or VFFS). The packaging machines keep running without interruption, even if the product or packaging material changes.

Innovative reference technology for all products.

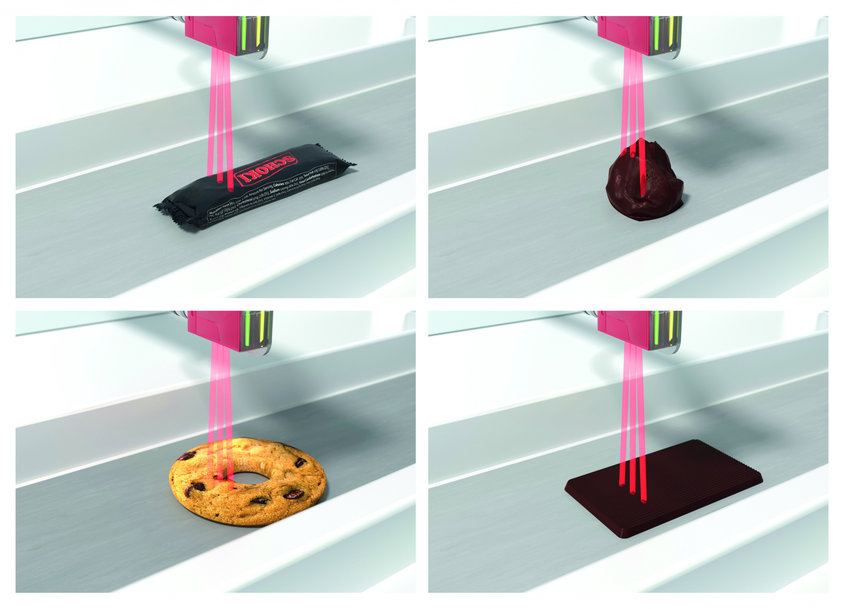

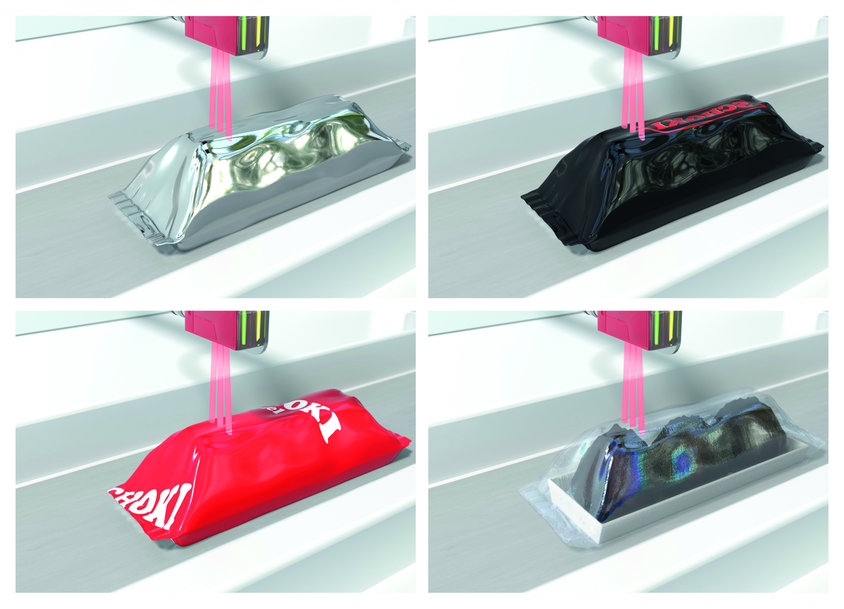

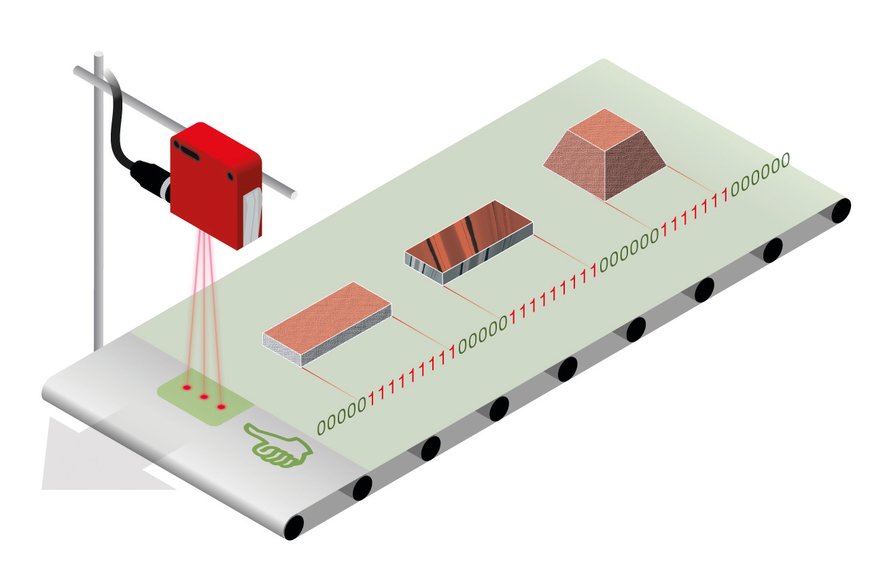

Leuze developed the DRT 25C dynamic reference diffuse sensor with its innovative detection method for precisely this area of application. The sensor works with three light spots and uses reference technology. The latter references the conveyor belt instead of the product and that is what makes this technology so unique. In the first step, the surface characteristics of the belt are taught in. This enables the sensor to subsequently detect all objects that do not correspond to the belt surface as "deviations", even if the conveyor belt is dirty or vibrating. With this approach, the surface properties of the products, such as the color, gloss, or transparency do not influence the detection. The DRT 25C uses its three light spots to reliably detect the entire spectrum: small, flat, or also tall and spherical products. Even irregular shapes and contours or products with openings, e.g. cookie curls, are detected. Thanks to the wide scanning range, these are also detected as a continuous piece.

Higher throughput due to reliable detection and zero setup time when changing products.

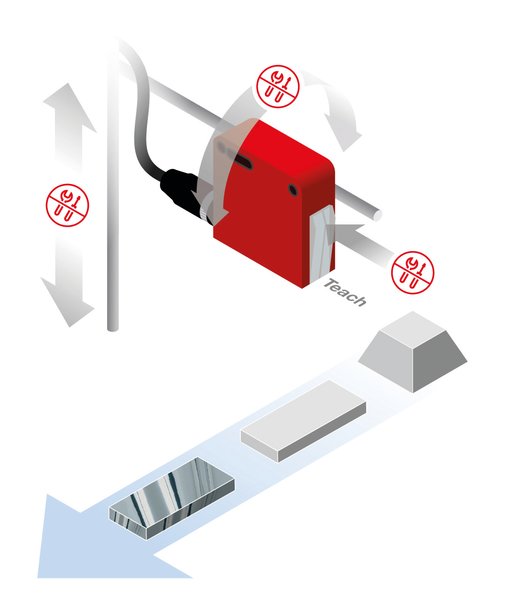

The reliable detection of objects – even those with challenging shapes and surfaces – guarantees a high machine throughput and prevents system standstills. Even under difficult conditions such as vibrations or contamination on the conveyor belt. No realignment of the sensor is needed when products or packaging materials are changed over. This significantly reduces the setup time required and enables higher product volumes. The DRT 25C is quickly and easily set up thanks to automatic teaching by means of the teach button. With a universal mounting position for all objects. Additional functions can be conveniently integrated into the machine control via IO-Link. For example a warning message for excessive debris, use of the counter built into the sensor, or locking the teach button.

www.leuze.com/drt25c

Three light spots ensure maximum reliability. The DRT 25C reliably detects the front edges of the objects, ensuring smooth processes and no machine downtime. The wide scanning range detects all types of products, even those with difficult geometries.

From transparent to high-gloss: The reference technology enables the detection of packaging with a wide range of colors and transparency as a "deviation" from the conveyor belt surface.

The teach button is used to teach-in the belt surface during the initial setup of the sensor. This means no additional setup time is required when changing products or packaging materials.

The DRT 25C works with the conveyor belt surface as a dynamic reference for the detection of objects. This is how the sensor reliably detects all objects that do not correspond to the belt surface, even in the case of contamination and vibration of the conveyor belt.