www.magazine-industry-usa.com

13

'20

Written on Modified on

A lot of power in a very small space

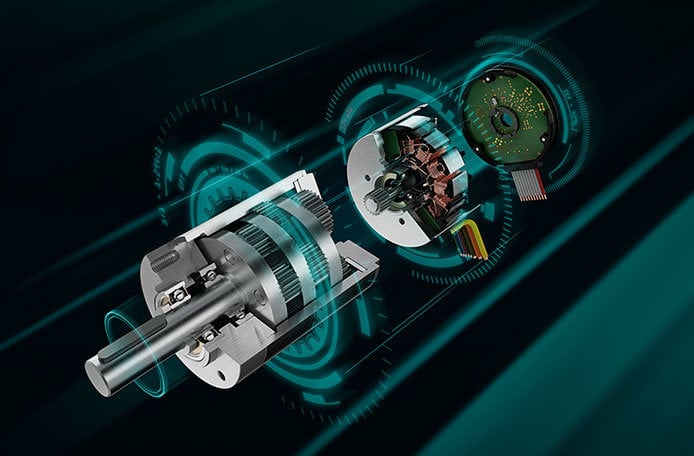

Drive Systems evolved. Generally speaking, electric motors are not "lone wolves" but for most applications need to be combined with gearheads for speed reduction as well as encoders. To ensure that the components are perfectly matched to each other and to minimise installation requirements, it is recommended to obtain the individual components as a complete solution from a single source. Even in cases where installation space is extremely tight and where high-torque drives are required which, owing to the installation situation, need to be as short as possible, there is a practice-oriented solution that is especially suitable for applications in robotics, prosthetic joints, laboratory automation, pumps, medical technology or aircraft cabin equipment.

Figure: The powerful and compact drive systems are ideal for applications in robotics, prosthetic joints, laboratory automation, pumps, medical technology or aircraft cabin equipment. (Copyright: Schunk, FAULHABER)

The drive specialist FAULHABER has once again demonstrated its competence as a system provider and has extended its BXT flat motor series by adding corresponding gearheads and integrated encoders as well as speed controllers that are also exceptionally short in the axial direction. All components have been optimised to ensure that they function perfectly together. The three sizes can solve many different drive challenges. In the case of a lower-arm prosthesis, for example, the smallest drive with a diameter of 22 mm would be ideal for the hand and the 16 mm long motor for the elbow. Other possible applications for the small compact drive systems are robot grippers, industrial automation, humanoid robots and even bio-robotics for motorised – i.e. power-assisting – hand exoskeletons. Thanks to their precise speed control properties, they are also suitable for e.g. dialysis machines or medical pumps.

Figure: Compact drive system from a single source: The high-torque flat motor series has been extended by the addition of matched gearheads as well as integrated encoders and speed controllers, which are also exceptionally short in the axial direction. (Copyright: FAULHABER)

Innovative winding technology for more torque

Metallic planetary gearheads with numerous reduction ratios

The GPT metal planetary gearhead family, which also impresses with compact dimensions and high torque, is suitable for speed reduction of the flat motors. The pure metal gearheads achieve performance values that are comparable to those of significantly more expensive technologies available, such as those that use ceramic components. The gearheads are available with motor-compliant diameters and offer reduction ratios from 3:1 to 1,294:1 with extremely fine graduations in up to four stages. Each stage was optimised for high performance with respect to torque and speed. Depending on the diameter, the gearheads achieve continuous torques of 1, 8 and 18 Nm. Higher torques are also possible for a short period.

Furthermore, the gearheads are extremely robust and tolerate continuous loads as well as rapid load changes. They have been developed for limited axial installation space and are significantly shorter than other models with the same diameter. The single-stage 22 mm version, for example, is only approx. 18 mm long and the four-stage version approx. 37 mm. With the 42 mm gearhead, the lengths are just under 31 mm and approx. 68 mm respectively.

Housed encoder with high positioning accuracy

All BXT motors are equipped with digital Hall sensors and, thanks to their large number of poles, their speed can be controlled very precisely. The IEF3-4096 magnetic encoder is available for precise positioning tasks. The encoder is fully integrated in the housed motor variant, thereby increasing the length of the overall drive by just 6.2 mm. Despite of the flat design, it offers three channels with index function, a Line Driver and a high resolution of up to 4,096 lines per revolution. The combination of motor and encoder is an ideal system solution in cases where extremely precise positioning must be performed in constrained spaces and, at the same time, high torques are required, e.g. in robotics, medical technology, laboratory automation or industrial automation.

Integrated speed controllers complete the product range

Beginning in April 2020, speed controllers will also be available for the BXT motors. They are integrated in the housed versions of the BXT motors and increase the length of these motors by just 6.2 mm. The well though-out design concept enables both the encoder and the speed controller to be installed in the same housing and also permits a large number of common parts to be used. Speed control is performed by the digital Hall sensors integrated in the motors. Thus, a wide speed range from 200 min -1 to 10,000 min -1 is available. The compact combination of motor and speed controller is ideal for space-critical applications and simplifies installation and commissioning.

www.faulhaber.com/evolved/en