www.magazine-industry-usa.com

07

'20

Written on Modified on

GEA Pavan installs seventh production line for Polish breakfast cereal producer

Earlier this year, GEA Pavan successfully handed over a seventh production line for manufacturing breakfast cereals to OBST S.A.. Both companies have been working in a close partnership for 20 years.

This long-lasting collaboration aims to turn marketable ideas into concrete and successful cereal products. The recent line addition will allow the Polish company to go to the market with innovative cereal products. In this case cereal shaped like pillows.

OBST – the Polish solution for high quality breakfast cereals

In the 90s, Polish consumers started to replace traditional morning food like “Jajecznica”, a large meal composed of eggs, sausages, with breakfast cereal. During the years that followed, the shelves of supermarkets in Poland began filling with corn flakes and other breakfast cereals that were produced outside the country. OBST saw the opportunity to break into a growing market, opened the company and partnered with GEA Pavan to provide a local source of breakfast cereals.

In 1997, OBST ordered its first line from GEA Pavan, creating the beginning of a strong strategic partnership. The business grew and OBST decided to increase production capacity by installing five more lines. It was a positive experience for OBST, and they confirmed GEA Pavan as a preferred supplier. With these six GEA Pavan lines, OBST produces 3.500 tons per year of breakfast cereal and exports into Europe, Africa and Asia.

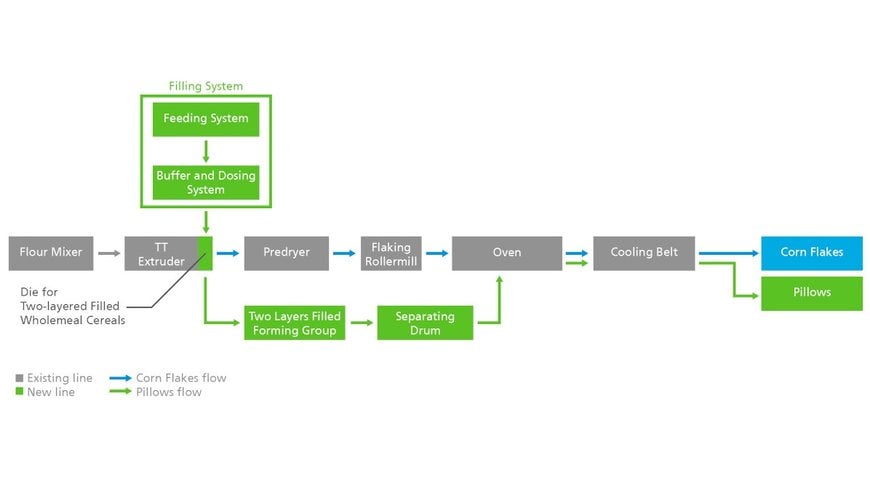

Starting from an already existing line used for corn flakes production (in grey), the added machinery (in green) can be transform the production line into a pillows production one. (Pic. GEA)

The new seventh line allows OBST to step into a new product area. Starting with one existing line used for corn flake production GEA added machinery, transforming the line into one that produces cereal pillows. The die for two-layered whole meal cereals is applied directly to the extrusion head, allowing the production of coextruded pillows. The filling system composed of a feeding system, a buffer and a dosing system, allows for filling of the pillow and it ensures perfect dosing calibration. The extruded product is initially processed by a two-layer forming unit which, by means of a roller, will give the product its typical pillow shape and at the end separated through a rotating drum. Once separated, the pillows are dried in the oven and, once cooled on the belt, are ready to be packaged and distributed.

Boguslaw Obst, founder of the company OBST S.A. in Poland. (Photo OBST/Beniamino Gelain)

GEA Pavan extrusion technology ensures high efficiency and product quality

“The GEA Pavan production lines assure high standards of quality and extreme flexibility. These are the most important factors in our success, as we now produce high quality breakfast cereals expressed in a range of 20 different products. We are able to serve the most demanding consumers with specific lines: healthy products, sugar free, with vitamins, wholegrains and also developed “super oat”, specifically formulated to reduce cholesterol,” explains Boguslaw Obst, founder of OBST S.A..

The GEA Pavan extrusion machines, like the TT Twin-screw extruder series makes this happen. The technology ensures high efficiency and product quality, enabling to production of a wide range of final products thanks to the perfect combination of time, temperature and mechanical input in the cooking phase.

GEA Pavan TT extruders (Photo OBST/Beniamino Gelain)

GEA Pavan R&D Team supports introduction of new recipes

The development of such a variety of products was also possible thanks to collaboration between the R&D departments of GEA Pavan and OBST. OBST’s R&D department is constantly working on introducing new innovative products by analyzing the latest developments, technical solutions and innovations in the field of production technology. GEA Pavan’s research and development (R&D) activities are performed by a team of 30 people including process technicians, analysts and mechanics. Their research is conducted in a 2000 sqm facility located in Italy. The facility is equipped with three pilot plants and four flexible production lines. A complete laboratory is equipped with instruments for chemical, chemical physical, rheological and nutritional / organoleptic analysis of food.

A technologist in OBST’s R&D department. (Photo OBST/Beniamino Gelain)

By testing new formulation at their Center in Italy, the R&D team supported OBST in developing recipes for new products. “This, added to a very interesting balance between costs and quality offered, made us very loyal to GEA Pavan, resulting in us continuing to develop new products and increasing our production capacity,” remarks Boguslaw Obst. “More than 20 years have passed since I decided to cooperate with GEA Pavan. I can confirm that this was the right decision,” Obst concludes.

www.gea.com