www.magazine-industry-usa.com

22

'12

Written on Modified on

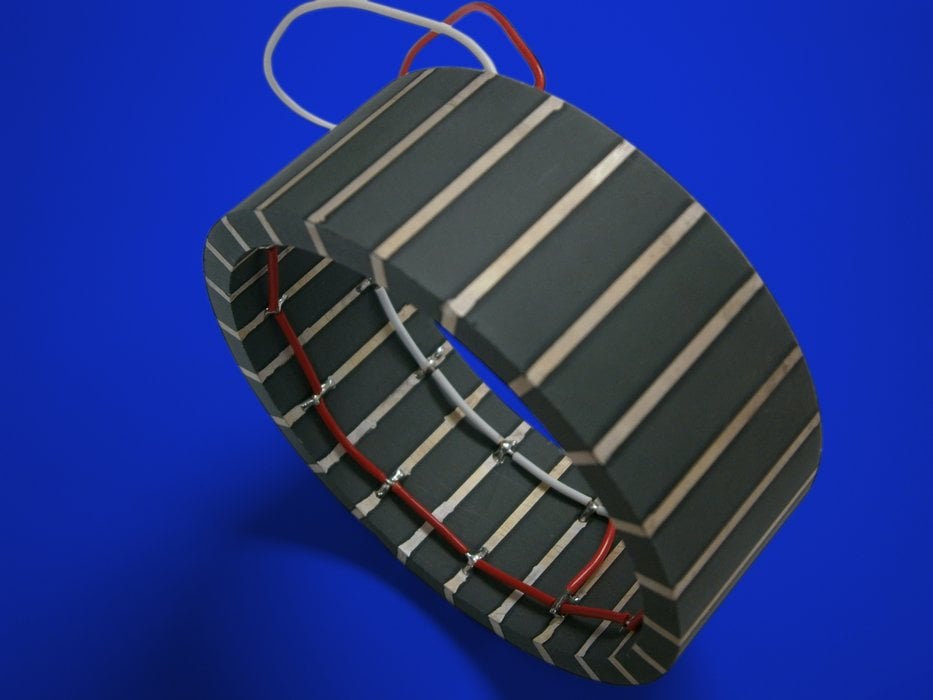

Morgan Technical Ceramics earns its stripes with revolutionary tube design

Morgan Technical Ceramics is promoting its range of striped tubes for the defence sector with an innovative design, offering lower frequency and increased drive for applications where high acoustic transmitting properties are required.

In contrast to a standard tube, which has three main resonance modes (length, wall and circumferential), Morgan Technical Ceramics’ innovative striped tubes have one main resonance – the circumferential mode. In 99 per cent of cases, circumferential mode (low frequency) is chosen for underwater transmission applications to allow the signal to move further away from the source.

Having focused and refined performance through the circumferential mode, the striped tubing features segments which are equally distributed around the circumference, and the space in between the positive and negative electrodes is generally greater than the wall thickness. As the distance between the electrodes is much larger, this allows a user to apply a much higher voltage, and thus achieve a higher acoustic output. If a strong, acoustic signal is needed from a standard tube, its wall thickness limits the higher vibrations achievable.

The striped tube range is available from 12.70 mm (1/2”) to 101.60 mm (4”) diameter tubes with lengths ranging from 10 mm to 75 mm (under ½” to 3”); Morgan Technical Ceramics can also make the product in 152.4 mm (6”) to 202.8 mm (8”) diameter tubes with lengths of up to 75 mm (3”). Larger or smaller sizes are available on request, dependant on available tooling.

The striped tubes are generally manufactured from PZT401 and PZT807 which are hard PZT materials for increased robustness and longevity but this offers low sensing properties. If a striped tube is required for receive/sensing, rather than transmission, Morgan Technical Ceramics can offer an alternative striped tube product made from a softer material such as PZT5A1 which is more sensitive. Applications for this would be more confined to commercial purposes, such as for bore hole investigation, oil exploration and drill navigation.

In receive/sensing mode a standard tube will see uniform pressure on OD/ID and voltage output will be proportional to the D33. In a striped tube, the same happens but the voltage is proportional to the D31 which is much lower than D33.

Richard Carus, product sales manager – Piezo Components for Morgan Technical Ceramics, said: “We work closely with our clients in the defence and security industries to listen and really understand their challenges. The launch of the striped tube range reflects our commitment to radical innovation and to bringing to life the products that our clients want and need. We believe that this ethos to work for our customers is what allows us to retain our position as leader in the design and manufacture of electro ceramic products for the security and defence markets.”