www.magazine-industry-usa.com

26

'12

Written on Modified on

2,000 Festo devices macros developed for EPLAN users

Partners, Festo and EPLAN, are each pushing forward with the goal of connecting the worlds of configuration in electrical and pneumatic engineering. Festo developed a data package specifically for EPLAN users with over 2,000 smart devices macros that now gives extra strength to the mechatronic orbit of the CPX terminal. Users of the EPLAN Platform can use this to simply and easily create overview drawings, electrical and pneumatic circuit diagrams, and PLC overviews.

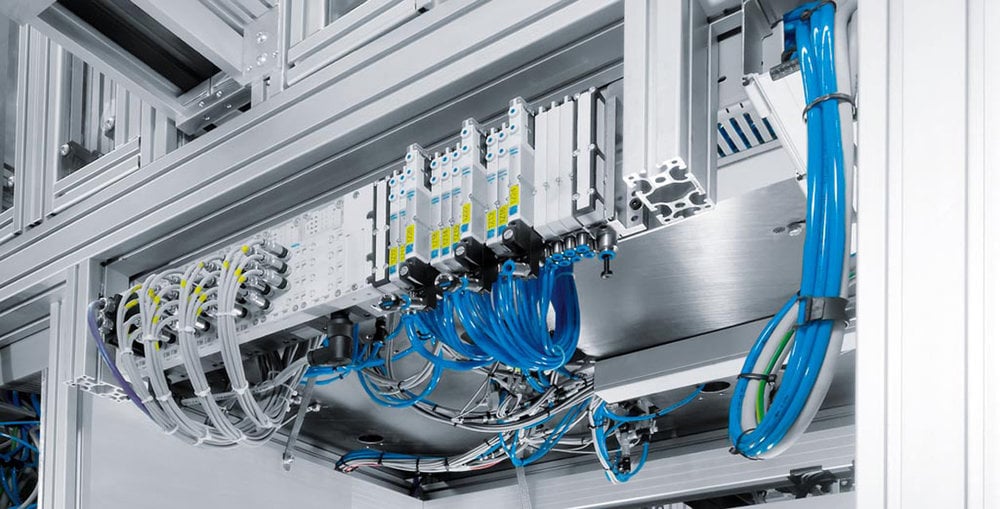

Modular, versatile and powerful: There are now

2,000 new device macros to help with rapid

planning of Festo CPX/MPA valve terminals

2,000 new device macros to help with rapid

planning of Festo CPX/MPA valve terminals

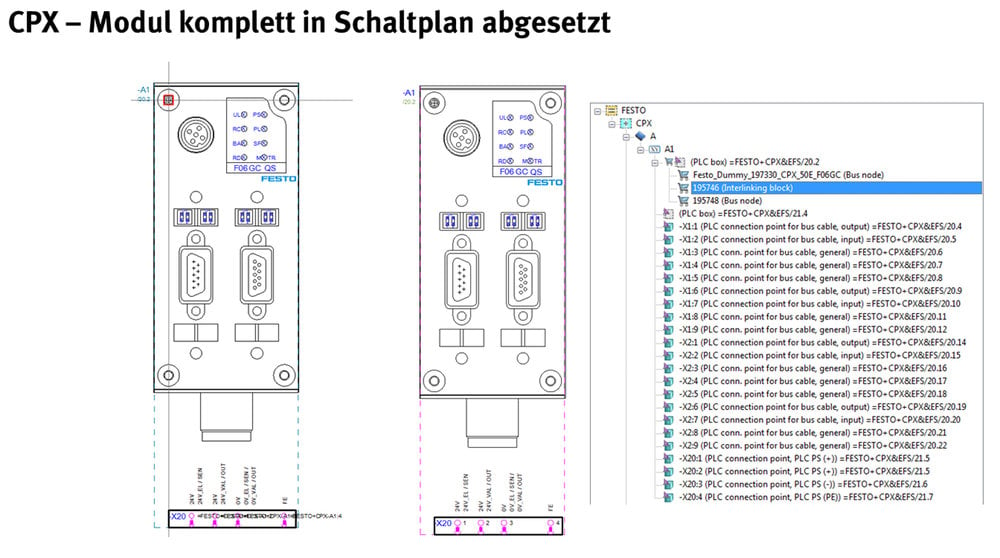

The new exclusive macro collection of over 2,000 device macros for valve terminals with Festo's CPX electric terminal brings together configurations in electrical and fluid project engineering. The device data is available in six languages and comprises intelligent module configurations that already contain their electrical and fluid engineering connection logic, including function templates. The final type code of the configured Festo valve terminal is the link. It comprises two ID codes, one for the electrical and one for the pneumatic section. The designer can use this ID code to select the most appropriate of the predefined device modules and place it by Drag & Drop into the electrical or fluid engineering documentation. Users of EPLAN Electric P8 and EPLAN Fluid can use this to simply and quickly easily create 2D overview drawings, electrical and pneumatic circuit diagrams and PLC overviews. The data can be downloaded from Festo's website at no charge (www.festo.de/EPLAN).

Versatile for any field of application

The benefits of guided configuration using Festo's tools are combined with logic-based documentation in EPLAN. Thanks to an individual combination of different functions, the valve terminal's configuration can be matched to the application precisely – wide ranges of application are guaranteed. The Festo CPX terminal is perfect here: electrical and open to all current field bus standards and all customer-specific installation standards. Customers benefit from ease of handling: out of the control cabinet into the plant, and network electrics and pneumatics, saving installation effort.

Free download

The macros, available for all CPX terminals (electrical peripheral equipment and field bus nodes) and some MPA valve terminals, contain the following functions and can be used as parts master data in the creation of the parts lists:

• Structural overview with individual module feeds and ordering code

• Circuit diagrams in all-pole representation, terminal diagram and PLC overview

• Overview of control cabinet with type codes and in a scale of 1:1

The data is available for download at no charge as a complete package from www.festo.de/EPLAN and can also be downloaded from the Festo online product catalogue under 2D/3D CAD. Availability through the EPLAN Data Portal is also in preparation.

Common target: user benefit

For years, Festo and EPLAN have worked together to develop solutions with the aim of making engineering easier for their common customers. For instance, Festo's mechatronic components can be designed and documented simply thanks to the direct connection between EPLAN Fluid and Festo's product catalogue. In addition, the subsidiary Festo Didactic has been distributing the EPLAN Education software for industrial foundation and further training for some years.

Overview of EPLAN macros for

Festo CPX terminals

About Festo

Festo is both a global player and an independent family-owned company with its headquarters in Esslingen am Neckar. The company provides pneumatic and electrical automation technology for 300,000 customers in over 200 industries. Its products and services are available in 176 countries worldwide. With about 15,500 employees in 59 national companies throughout the world, Festo generated revenues of € 2.1 billion in 2011, of which 8.5% is invested annually in research and development. As a learning company, Festo invests 1.5% of its revenue in education and training. Learning opportunities are not just for employees: Festo Didactic GmbH provides industrial education and training programs in automation technology for customers, students and trainees as well.