www.magazine-industry-usa.com

30

'12

Written on Modified on

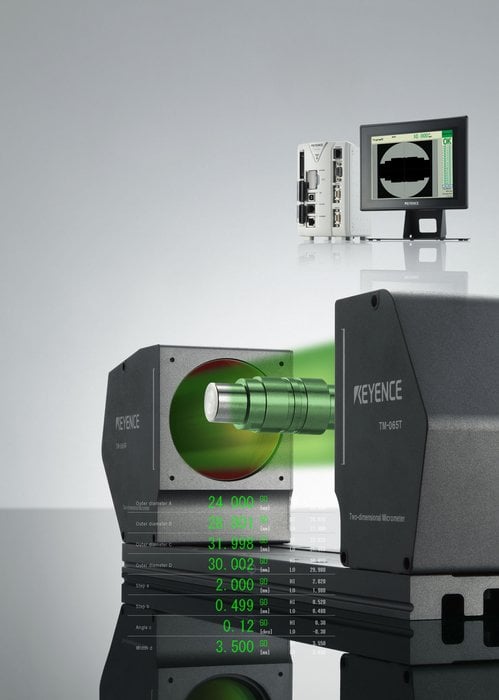

TM-3000 : 2D Optical Micrometre.

First of its kind in the world: this new sensor performs on line two-dimensional measurement with a micron precision.

This 2D optical micrometer is equipped with a high-speed computing CPU and two dedicated image processing DSPs. Using a total of four processors for parallel processing, it allows for fast processing of 1800(images)/minute.

A stable measurement to micron precision

The 2D optical micrometer uses a dual telecentric optical system with a uniform collimated light beam. The two-dimensional CMOS array detects the light and dark edges in the received light, and measures the target dimensions. With the dual telecentric system the variations of the image projected on the CMOS according to the target position based on the receiver are suppressed. Thus high precision measurement is achieved by performing subpixel processing offering an accuracy of 0.5 μm to 3 μm according to the models for a repeatability of +/- 0.06 μm à +/- 0.2 μm.

16 measurement points without changing the target position

As the TM-3000 Series is two dimensional, it can measure up to 16 points on the part to control. This system combines more than 15 measurement modes thus answering to the very large majority of applications: hole diameters, distances between centres, measurements of diameter, co-ordinates of points of intersection, measurements of angle, height, step, distances to a perpendicular, radius, outer diameter… Moreover, the TM-3000 Series position adjustment automatically corrects the target misalignment and tilting, performs an accurate measurement even when positioning is difficult or when objects move randomly. Thus, the adjustment is very simple and there is no need for an accurate repositioning mechanical system of the part to control.

Simple programming and visualization can be carried out with or without a PC. Thanks to the measured values history and shapes saved, the TM-3000 Series provides tracking data. The measurement range reaches 65 mm for a maximum distance of 270 mm between the transmitter and the receiver. The LED technology used offers an exceptional stability and a very long lifespan.