www.magazine-industry-usa.com

29

'12

Written on Modified on

EPLAN, Kiesling and Komax present Control Panel Manufacturing Automation at IMTS – Booth E-4501

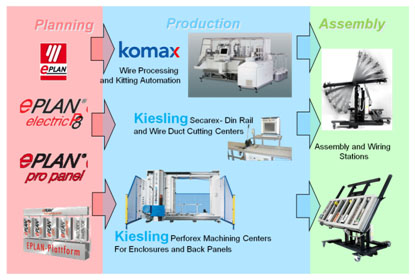

Today the manufacturing of control panels is traditionally a labor intensive process with few options for process automation. Most operations are done manually including engineering, laying out, punching and drilling back panels and enclosures; cutting to length, stripping crimping and labeling wires, installing components and wiring panels.

For the preparation of the control enclosures and back panels, CNC machining centers, Kiesling Maschinentechnik uses technology such as the Perforex machine which is designed for the automated modification of off-the-shelf industrial enclosures as well as drilling and tapping the associated component mounting panel. The Perforex system is designed to work on both flat work pieces like mounting panels, doors and modular surfaces as well as all surfaces of three dimensional welded enclosure bodies. These special CNC centers provide a reduction of up to 30 percent of the total costs on each control panel, even more so when it comes to single piece production. They also improved quality with no rework of expensive painted and stainless steel enclosures; the automated technology drives process standardization on the shop floor with faster lead-times in mechanical prefabrication, meaning faster turn-around overall.

For the last piece to this Automation equation is the wire preparation. Komax Wire offers machines that can perform functions from measuring the wire to length, cutting and stripping with the Kappa line to the advanced Zeta systems for processing wire kits suited for panel wiring. The Zeta can process up to 36 different wires and can be equipped with up to 8 different processing stations and up to 2 inkjet marker; it selects wires automatically, cut them to length, inkjet marks them and terminates them. Termination possibilities can include insulated ferules or compacting the wire ends with ultrasonic or resistance welding. Chain and normal bundle can be defined for each wire in the same sequence. Wires for back panels or enclosures can be produced and kitted in the ideal order. The optimized order is maintained until wires are installed in the cabinet, meaning the cabinet is wired quickly and orderly with missing wires being a thing of the past. Components with different terminal contacting such as spring-loaded, push-in or conventional terminals can have one or both ends automatically inserted in the same sequence directly at the machine while at the same time, chain bundling non inserted wires.

These three companies have partnered together to provide customers, with not only individual technologies, but a complete solution for Control Panel Manufacturing. Without further efforts, Pro Panel takes the layout design data and exports the information to Kiesling Perforex system and to the Komax Zeta automatic wire harness processing machine. In a 3D environment, you can layout your design panel, align and position components exactly, follow spacing requirements and automatically calculate wire lengths.

As with any automation technology, correct data is extremely important as there is no longer the opportunity for manufacturing personnel to make on-the-fly corrections to the engineering layouts due to “tribal knowledge”.

These companies, EPLAN Software and Services, Komax Wire and Kiesling Maschinentechnik will demonstrate a combination of their technologies which streamline the quality critical and resource draining activities involved in the control panel industry. Live demonstrations of this solution will be held in Chicago this September 10 – 15, at the Industrial Automation North America show booth #E-4501 directly across the aisle from the Rittal Corporation.

Van Miller is the North American Sales Representative for Kiesling USA with 10 years of experience in the control panel industry. For more information, please contact Van at This email address is being protected from spambots. You need JavaScript enabled to view it.

Patrick Boyer is the Harness Machine Product Manager for Komax Wire with 17 years of experience in the wire processing industry. For more information, please contact Patrick at This email address is being protected from spambots. You need JavaScript enabled to view it.

Christine Knapik is the Marketing Communication Manager at EPLAN Software and Services. For more information, please contact Christine at This email address is being protected from spambots. You need JavaScript enabled to view it.