www.magazine-industry-usa.com

20

'20

Written on Modified on

NORD Gear to Showcase Gear Units for Poultry Processing Industry at IPPE 2020

From conveying to pumping to packaging, heavy washdown environments are no problem for NORD’s high-performance drive systems

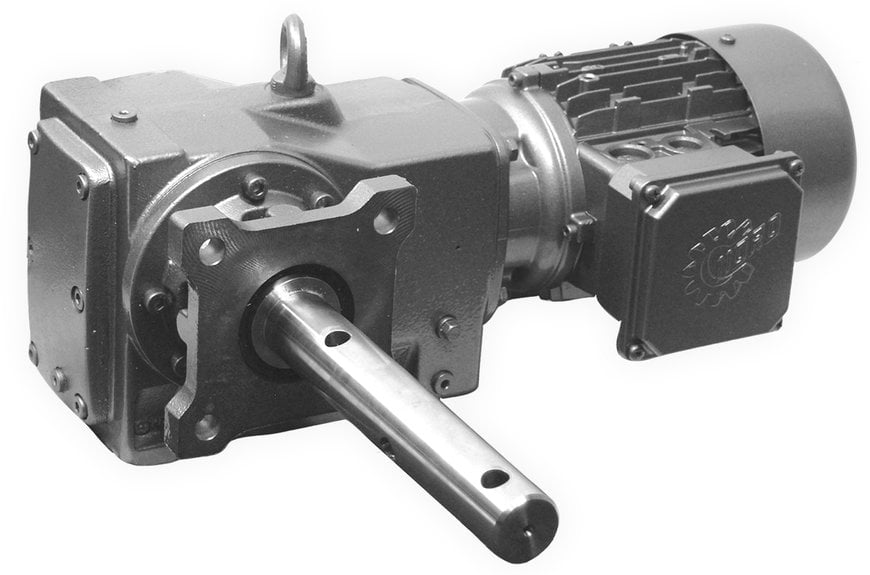

NORD's overhead conveyor drives feature heavy-duty construction and high-quality machined components.

NORD Gear Corporation, a world leader in drive technology, will showcase a variety of its solutions for the poultry industry at the International Production & Processing Expo (IPPE), January 28-30 in Atlanta. As the world's largest annual poultry, meat, and feed industry event of its kind, this year’s IPPE will bring together more than 32,000 buyers and sellers from around the globe.

Visit booth #7865 in Hall B at the Georgia World Congress Center to meet with experts from NORD and learn how the company’s intelligent drive solutions are helping poultry processing and production facilities improve operational efficiencies.

Featured products at the booth will include:

Overhead Conveyor Drives – Designed specifically to meet the needs of poultry and other meat processing applications, NORD's overhead conveyor drives feature heavy-duty construction and high-quality machined components.

With high efficiency performance and low maintenance requirements, these drives have a very low total cost of ownership while providing clean and reliable operation in food processing plants around the world. Mounting flange and output shaft ensure an easy, drop-in fit with industry-standard footprints.

Key Advantages:

-High overhung load capacity

-QUADRALIP™ sealing system

-Spread bearing design with dry cavity for optimized oil leakage protection

-Low maintenance, long service life

-Gear efficiency up to 95%

-Three sizes available to accommodate a wide range of applications

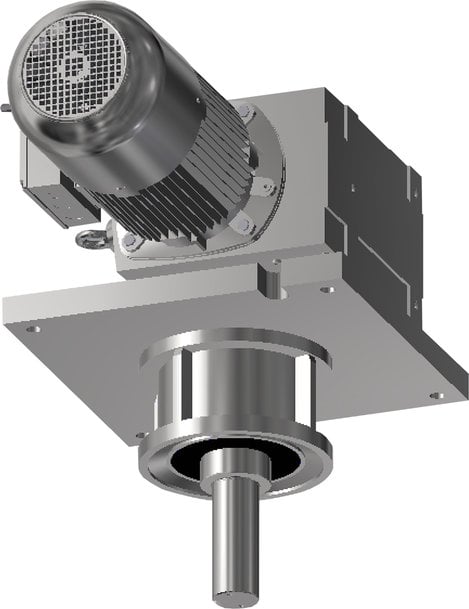

Screw Conveyor Package – The NORD Screw Conveyor Package offers a cost-effective drive solution in a powerful, compact footprint. Closely stepped speed reduction ratios combined with a directly coupled gearmotor or NEMA C-face input design eliminates the need for top motor mounts, pulleys, belts, or guards. Minimizing parts and eliminating the belted input systems provides for easier system maintenance, increased reliability, and superior drive performance.

Key Advantages:

-Reduced operation costs

-Large ratio range

-Direct drive motor options (Integral or C-face)

-No belt maintenance or belt guarding required

-Reduced parts / higher reliability / space savings

-Higher efficiency

-More direct torque transfer

nsd tupH™ – With nsd tupH, NORD provides a comparable alternative to stainless steel at a fraction of the price. Our special molecular conversion process ensures aluminum alloy drive equipment has all the surface protection food and beverage applications demand. Corrosion-resistant, easy to clean, lightweight, durable, dissipates heat more effectively than stainless steel, and will not blister or flake.

Products available with nsd tupH:

-Helical inline, helical bevel, and FLEXBLOC® gear units

-Smooth body motors

-NORDAC® START and NORDAC BASE electronic drive solutions

Learn more about the products that will be on hand at the NORD booth and download a new brochure on how NORD solutions are used by the poultry industry.

NORD manufactures a wide selection of gearboxes, electric motors, and drive electronics in various sizes and configurations for companies in intralogistics, food and beverage, airport baggage handling, grain and bulk materials, and other demanding markets. The modular design offers unlimited versatility with more than 20,000,000 combinations of totally unique gear motors and speed reducers available – in-line or right-angle, mounted by foot or flange, featuring solid or hollow shafts – to give customers complete freedom to specify a drive solution that’s perfect for the job. For more information, visit www.NORD.com, call 888-314-6673, or e-mail This email address is being protected from spambots. You need JavaScript enabled to view it..