www.magazine-industry-usa.com

25

'11

Written on Modified on

NKE develops bearing unit for pump applications

In collaboration with a large pump maker, NKE has developed a new modular system for the bearing arrangements to rationalise a whole pump generation. The bearing solution simplifies mounting and handling, therefore reduces costs.

The original objective was the rationalisation of a complete pump family. Therefore a module of twelve different sizes for fixed and non-locating bearing positions should be developed. A very important requirement was to ensure easy mounting and dismounting of the bearing unit on the shaft and the pump casing without the need of special mounting instruments. The bearing unit should also be protected against splash water and ensure a maintenance-free period of three years without additional lubrication. NKE succeeded in developing a bearing arrangement composed of six components which met all the customer’s requirements. For the whole pump family consisting of 48 different models, only 21 different types of angular contact ball bearings and deep groove ball bearings were used.

A special challenge was the development of the bearing unit for high performance pump models. on the locating bearing position, pairs of angular contact ball bearings were applied in order to resist high loads and to guarantee a long service life. Instead of individual installation, NKE found a solution to mount the bearing pairs into the pumps as entire units.

The advantages of this new bearing unit are easy mounting and simple handling, due to the deployment of one component instead of several single parts. This also simplifies the spare part service. Thanks to lifetime lubrication the maintenance costs are virtually eliminated. The rationalisation of the bearing arrangements also decreases production costs. This system is so well accepted by the end customers that NKE’s partner is planning to covert all types of pumps to this new modular system.

Captions:

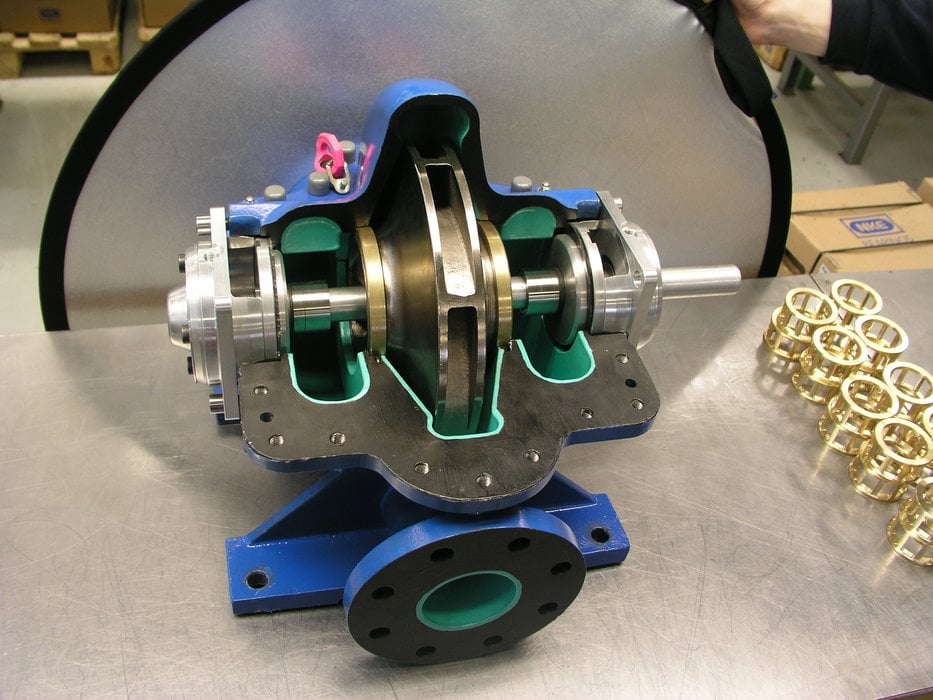

Picture 1: Cut-away model of a pump with NKE bearing units

Picture 2: NKE special bearing unit with housing for pumps

Picture 3: Caption: Bearing arrangement of an impeller shaft

A special challenge was the development of the bearing unit for high performance pump models. on the locating bearing position, pairs of angular contact ball bearings were applied in order to resist high loads and to guarantee a long service life. Instead of individual installation, NKE found a solution to mount the bearing pairs into the pumps as entire units.

The advantages of this new bearing unit are easy mounting and simple handling, due to the deployment of one component instead of several single parts. This also simplifies the spare part service. Thanks to lifetime lubrication the maintenance costs are virtually eliminated. The rationalisation of the bearing arrangements also decreases production costs. This system is so well accepted by the end customers that NKE’s partner is planning to covert all types of pumps to this new modular system.

Captions:

Picture 1: Cut-away model of a pump with NKE bearing units

Picture 2: NKE special bearing unit with housing for pumps

Picture 3: Caption: Bearing arrangement of an impeller shaft