www.magazine-industry-usa.com

25

'11

Written on Modified on

Drypack: the plug and dry solution for processing biogas

In Germany and throughout the world, more than 1,000 biogas dehumidification installations have already been equipped with CIAT systems. The Drypack range is the optimised result of CIAT's combined experience and expertise in processing the different sources of biogas up to 6,000 Nm3/h.

Conscious of the stakes in terms of energy and the environment, CIAT implements an ENERGY & ENVIRONMENT segment which targets all the sectors of WASTEWATER, WASTE and ENERGY. Drawing on many years of experience in heating, cooling, dehumidification, heat recovery and air quality, and to a rich product offer as yet unrivalled, CIAT offers coherent and consistent system approaches that have proven their reliability. This is reflected in the fact that CIAT has become the leading player in Europe for Biogas conditioning.

Biogas offers enormous potential for savings in the production of electricity, heat or biomethane. In its raw state, it contains many impurities (H2S, NH3, siloxanes, etc.) and a large amount of water vapour. This vapour reduces energy efficiency and compromises the service life of the recovery systems, in particular the engine and purification equipment. Drypack is an efficient dehumidification solution that is easy to install and maintain for farmers, industrial plants, wastewater treatment plants, waste facilities, etc.

Drypack is more profitable, more reliable, more simple. More profitable, thanks to a high level of dehumidification which guarantees effective motor protection and increases energy efficiency. More reliable, because it is entirely developed and manufactured by CIAT, giving the security of a reliable industrial process and a single partner. More simple, because Drypack is available in frame-mounted versions allowing rapid installation and connection to the digester and the engine.

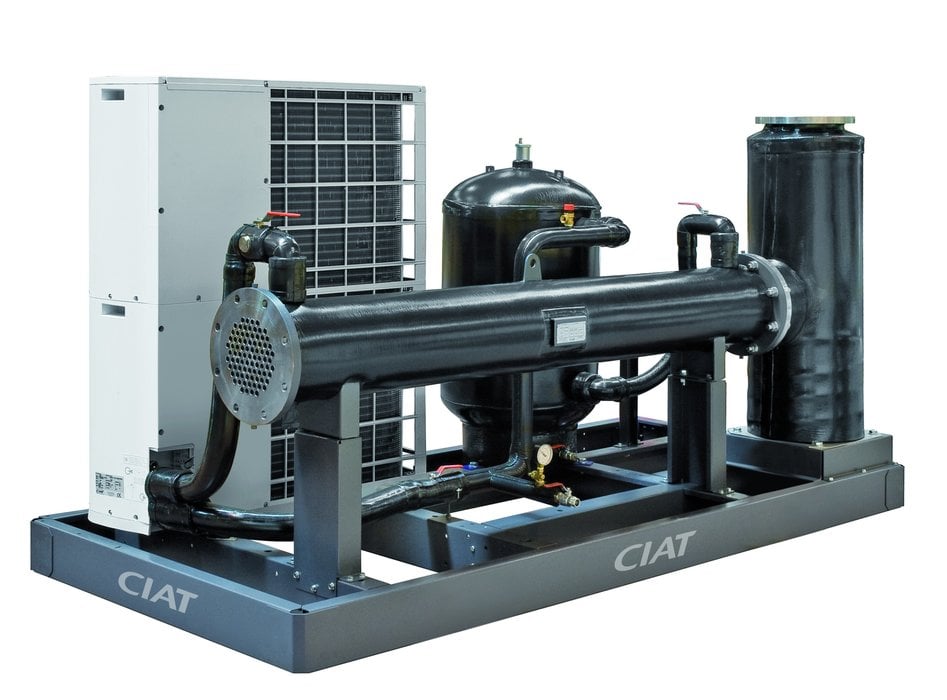

Drypack integrates shell and tube exchangers, a water chiller and a droplet separator in a homogeneous system either mounted on a frame or ready to assemble. 3 versions are available: Drypack One, Drypack Flex and Drypack Plus. They guarantee performance and profitability by combining optimised heat exchange, chiller energy efficiency and highly efficient droplet separation.

Drypack One, processing up to 800 Nm3/h of biogas, is an offer comprising 8 models configured to suit the most common operating conditions of agricultural biogas installations. These skids are equipped with AQUALIS or AQUACIAT chillers. An optional post heater may be installed which allows the relative humidity to be reduced by heating the biogas via recovery of calories from the engine. This solution requires low investment and has low operating costs.

Drypack Flex, with processing capacities up to 2500 Nm3/h, represents the best compromise between adaptation to needs and ease of installation. CIAT selects and optimises the system components to match the installation-specific data. The system is delivered on a frame with all the advantages of “Plug & Dry”. This solution can include an economizer, namely an auxiliary exchanger which reduces the cooling capacity and provides post heating with no need for additional outside heat. This equipment significantly reduces the operating costs.

Drypack Plus is the most powerful offer, up to 6000 Nm3/h, and the one that provides the greatest freedom in terms of adaptation. Whatever the type of gas, flow rate, temperatures and moisture content, CIAT components offer unlimited combinations. It can, for example, integrate a precooling function that is carried out via a tubular heat exchanger connected to a drycooler which sheds the load from the chiller and reduces the energy consumption of the system. This precooling greatly reduces the overall operating costs.

Biogas offers enormous potential for savings in the production of electricity, heat or biomethane. In its raw state, it contains many impurities (H2S, NH3, siloxanes, etc.) and a large amount of water vapour. This vapour reduces energy efficiency and compromises the service life of the recovery systems, in particular the engine and purification equipment. Drypack is an efficient dehumidification solution that is easy to install and maintain for farmers, industrial plants, wastewater treatment plants, waste facilities, etc.

Drypack is more profitable, more reliable, more simple. More profitable, thanks to a high level of dehumidification which guarantees effective motor protection and increases energy efficiency. More reliable, because it is entirely developed and manufactured by CIAT, giving the security of a reliable industrial process and a single partner. More simple, because Drypack is available in frame-mounted versions allowing rapid installation and connection to the digester and the engine.

Drypack integrates shell and tube exchangers, a water chiller and a droplet separator in a homogeneous system either mounted on a frame or ready to assemble. 3 versions are available: Drypack One, Drypack Flex and Drypack Plus. They guarantee performance and profitability by combining optimised heat exchange, chiller energy efficiency and highly efficient droplet separation.

Drypack One, processing up to 800 Nm3/h of biogas, is an offer comprising 8 models configured to suit the most common operating conditions of agricultural biogas installations. These skids are equipped with AQUALIS or AQUACIAT chillers. An optional post heater may be installed which allows the relative humidity to be reduced by heating the biogas via recovery of calories from the engine. This solution requires low investment and has low operating costs.

Drypack Flex, with processing capacities up to 2500 Nm3/h, represents the best compromise between adaptation to needs and ease of installation. CIAT selects and optimises the system components to match the installation-specific data. The system is delivered on a frame with all the advantages of “Plug & Dry”. This solution can include an economizer, namely an auxiliary exchanger which reduces the cooling capacity and provides post heating with no need for additional outside heat. This equipment significantly reduces the operating costs.

Drypack Plus is the most powerful offer, up to 6000 Nm3/h, and the one that provides the greatest freedom in terms of adaptation. Whatever the type of gas, flow rate, temperatures and moisture content, CIAT components offer unlimited combinations. It can, for example, integrate a precooling function that is carried out via a tubular heat exchanger connected to a drycooler which sheds the load from the chiller and reduces the energy consumption of the system. This precooling greatly reduces the overall operating costs.

Contact:

CIAT

Marc SCHALLER

This email address is being protected from spambots. You need JavaScript enabled to view it.

CIAT

Marc SCHALLER

This email address is being protected from spambots. You need JavaScript enabled to view it.