www.magazine-industry-usa.com

21

'11

Written on Modified on

AOD ™ pumps computer selection advantage

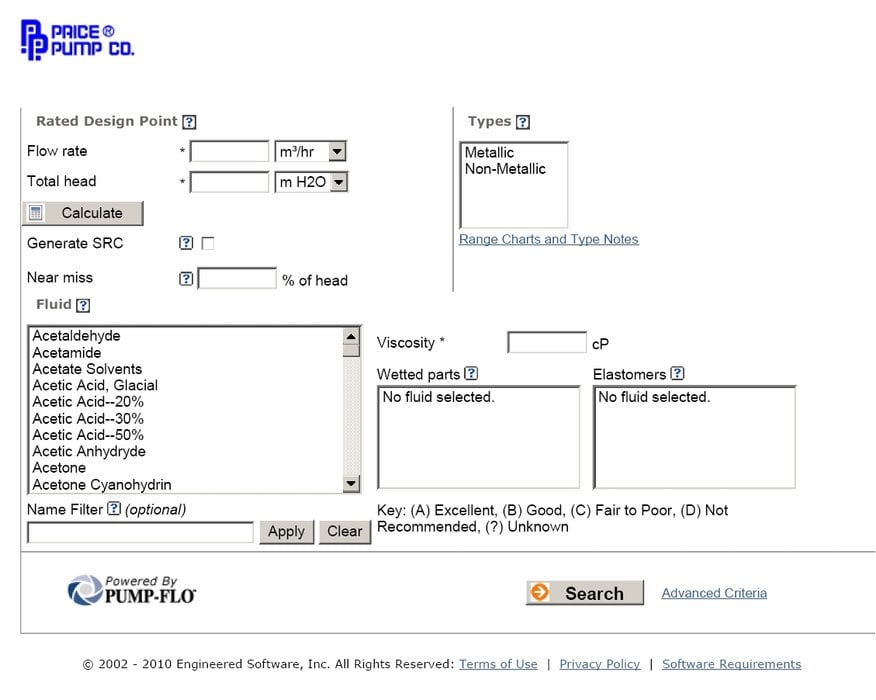

AOD ™ (air operated diaphragm) pumps are available in 7 sizes to handle flow rates from a few cc/min to 52m3/hour. Selection of this type design is important for maximum performance and minimum maintenance. Optimum pump selection is now possible with the PSI computer selection program available over the Internet.

The computer program starts with the flow rates, heads, viscosity and fluid itself. After entry, various models are displayed to meet the inserted specifications. One more click and the curves are presented for the respective offered models. This allows the comparison of various sizes to meet the application needs.

A complete pump model is outlined and displays suggested wetted parts for the AOD pump.

Once the model is selected, based on the fluid requirements, the AOD offers a unique low maintenance product with the fewest air valve components of any of the other AOD suppliers. With the low parts count this means fewer parts to fail in the valve section. The valve section is patented and is only available from AOD™.

All major metal group and engineered plastics such as polypro, PVDF and PTFE can be selected to meet the fluid requirements.

To complete the correct pump installation, a wide range of accessories pulsation controls, air regulators and diaphragm monitors can be supplied.

The end result of all this process is a correctly selected pump with a low maintenance air valve design. AOD offers the most cost effective solution to pumping of clear or solids laden fluids.

Applications can be found in most industry sectors: process, chemical, ceramics, construction, food processing, mining, plating and finishing, pharmaceutical, pulp and paper, refineries, marine, water and sewage treatment or automotive.

A complete pump model is outlined and displays suggested wetted parts for the AOD pump.

Once the model is selected, based on the fluid requirements, the AOD offers a unique low maintenance product with the fewest air valve components of any of the other AOD suppliers. With the low parts count this means fewer parts to fail in the valve section. The valve section is patented and is only available from AOD™.

All major metal group and engineered plastics such as polypro, PVDF and PTFE can be selected to meet the fluid requirements.

To complete the correct pump installation, a wide range of accessories pulsation controls, air regulators and diaphragm monitors can be supplied.

The end result of all this process is a correctly selected pump with a low maintenance air valve design. AOD offers the most cost effective solution to pumping of clear or solids laden fluids.

Applications can be found in most industry sectors: process, chemical, ceramics, construction, food processing, mining, plating and finishing, pharmaceutical, pulp and paper, refineries, marine, water and sewage treatment or automotive.