www.magazine-industry-usa.com

01

'19

Written on Modified on

Kennametal Makes Hard Turning More Cost-Effective

New KBH10B and KBH20B PcBN grades deliver higher productivity and lower cost per part

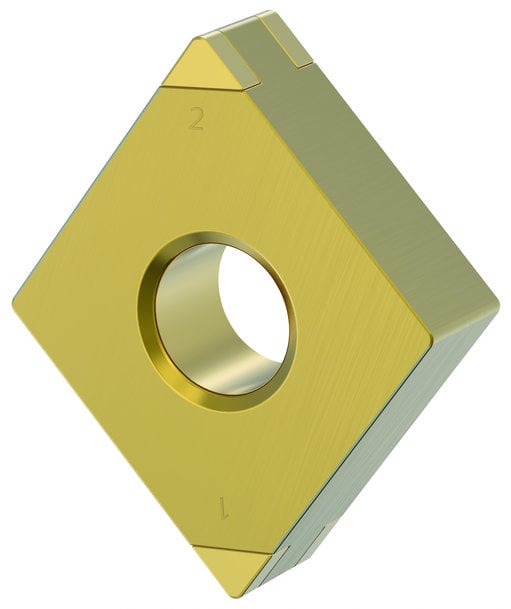

Kennametal today announced its latest innovation in hard turning-KBH10B and KBH20B PcBN grades, double-sided inserts for materials up to 65 HRC.

The new grades are specially designed to deliver higher productivity and longer tool life when turning tool steels and other hardened materials.

“Kennametal’s new KBH10B and KBH20B grade inserts are an excellent choice for high-volume production of hardened gears, shafts, bearings, housings, and other drivetrain components, where tooling cost per part is an important metric”, said Robert Keilmann, Product Manager, Turning.

Polycrystalline cubic boron nitride (PcBN) mini-tipped inserts have long been recognized as a great option for reducing part cost when turning hardened steel components. Kennametal’s new grades of PcBN inserts improve upon that value proposition by delivering increased productivity with a lower cost per part. Features include:

-Patented ceramic binder structure and TiN/TiAlN/TiN coating that provides extreme wear resistance even at elevated cutting speeds.

-A gold PVD coating makes it easy to identify when an insert needs indexing, while the numbered corners assure that a machine operator won’t inadvertently switch to a used edge.

-Two edge preparations in a “trumpet” style hone for heavier and interrupted cuts, and a light hone for continuous turning. Both are free-cutting, further extending tool life and generating surface finishes down to 0.2 Ra.

-The PcBN mini-tips are offered in four insert shapes—three rhomboidal and one triangular—which means up to six cutting edges per insert.

Kennametal’s new KBH10B (45% PcBN content) and KBH20B (60% PcBN) mini-tip: two grades, four shapes, a variety of corner radii, and twice as many cutting edges per insert.