www.magazine-industry-usa.com

07

'19

Written on Modified on

Safety via Slip Ring

Safe Torque Off: Kollmorgen and Stemmann-Technik are developing a TÜV-certified solution

The combination of Safe Torque Off and single-cable connection technology enables streamlined installation with AKD-N servo drives from KOLLMORGEN arranged in a distributed setup.

Author: Felix Haunschild, Safety Development, Kollmorgen Europe, Ratingen

Slip rings emerged at the same time as electric motors and generators. The operating principle, which involves sliding contacts on rotating circular conductors, is essentially fairly simple. Any issues relate to matters of detail, and these are the things that currently present the main challenge to developers – with regard, for example, to the growing role of safety technology in the field of engineering. For one thing, it is not that easy to transfer data, energy, air, or fluids from a static location to a component in constant rotation. The motion control experts at Kollmorgen have now managed, together with the slip ring manufacturer Stemmann-Technik, to develop a TÜV-certified safety solution – with UL approval – for this kind of thing.

Rotary indexing tables are a common piece of equipment used in an assembly and test stand context. Various work stations are arranged around an outer radius and take the component, held in a workpiece carrier, through another production stage with each indexing operation. If the workpieces on the rotating table still require rotational or linear positioning as well, the drives need to move as well. The job of slip ring systems is to transfer the power required for this along with the relevant control data. This is an established technology and works reliably well throughout a long service life. Things really get exciting, however, when this kind of slip ring is used to transfer safety-related data too. This was the task facing Kollmorgen as part of a project for a manufacturer of measurement inspection machines, with the aim being to investigate the behavior of crystalline components.

Benefits of distributed servo technology

The idea behind the engineering project was to install not only the actuators but also the controls on the rotary indexing table – adopting a distributed arrangement to save space. The Kollmorgen solution to this task was to use single cable connection technology, with the option to loop from drive to drive, also improved the inertia of the rotary indexing table. But it was still necessary to satisfy the safety technology requirements. This is integrated into the test station in the central AKD-C power supply module, which means a connection to the servo axes is required.

The Safe Torque Off (STO) feature was needed because the masses being moved – the rotary indexing table has a diameter of 120 cm after all – present a potential hazard to persons in the vicinity. The testing process does, however, envisage some operator intervention on the system, which ultimately implies Safe Torque Off as regards evaluating safety.

The central AKD-C power supply module does in fact feature STO as standard – albeit connected to clearly defined and certified cables. Using a slip ring as a connecting element between the central AKD-C power supply module and the AKD-N drives would inevitably mean disconnecting the cable, however, and invalidate certification. The same also applies to any existing UL approval. This too would no longer be effective.

Safety in the slip ring – with a certificate

As part of the joint engineering project with the test stand builder, Kollmorgen began to look for a suitable manufacturer of slip rings who would be willing and able, together with the servo drive and motion control specialists, to develop a safety slip ring with TÜV certification. The current solution, approved by TÜV Süd, is based on a slip ring from the Bako LP range from Stemmann-Technik. Compared with conventional slip rings, this transmission system (made in the German town of Schüttorf) offers a wide range of potential solutions for customized production – thanks to the numerous options available – along with UL approval.

The challenges associated the project included how to deal reliably, from a safety perspective, with the natural wear experienced by the contacts. In this regard, Stemmann-Technik would point out the reliable service life based on 35 million revolutions at maximum speeds of up to 80 rpm. Another challenging task was how to transmit safety signals reliably without interference. It should be noted here that the shielding integrated into the cables is no longer present in the slip ring. This then makes it necessary to find ways of preventing signaling errors caused by the coupling of interference signals.

Interference-resistant communication of signals

Kollmorgen and Stemmann-Technik are able to combat the familiar problems associated with EMC through two separate measures. From a design perspective, two shielded junction boxes in the safety slip ring interrupt the Ethercat communication supply via which the superimposed safety signal is transmitted. This ensures in particular that the magnetic influences from harmonics in the power wires do not cause any signal interference. The second aspect for ensuring high resistance to interference within the slip ring relates to the structure of the safety signals. Compared with the standard practice of arranging STO with 5 or 24 VDC signals, Kollmorgen uses AC signals with specific frequency patterns between the AKD-C, as the central module, and the distributed AKD-N servo drives.

In practice, this particular detail ensures that potential interference signals from the drive are completely ignored if they do not have the exact same frequency. This approach is therefore far more robust against interference – which ultimately, combined with the two separate junction boxes for power and signals, helped secure certification from TÜV Süd. Thanks to this equipment, engineering firms have the benefit of safely switching off the rotary indexing table without losing access to the positioning drives (which are also moving) for the workpiece carriers. Users also retain full access to all drives in the event of an emergency stop – which ultimately saves on time-consuming referencing as a result of undefined statuses.

Conclusion

The new safety slip ring solution, developed jointly by Kollmorgen and Stemmann-Technik, means users do not have to miss out on the benefits of drive-based safety technology. Even for applications involving slip rings. So certification of STO in the slip ring paves the way for streamlined solutions for incorporating Safe Torque Off into applications involving rotation – including with innovative single-cable connection technology and servo drives arranged in a distributed setup. And as far as the US market is concerned, this solution would also retain UL certification.

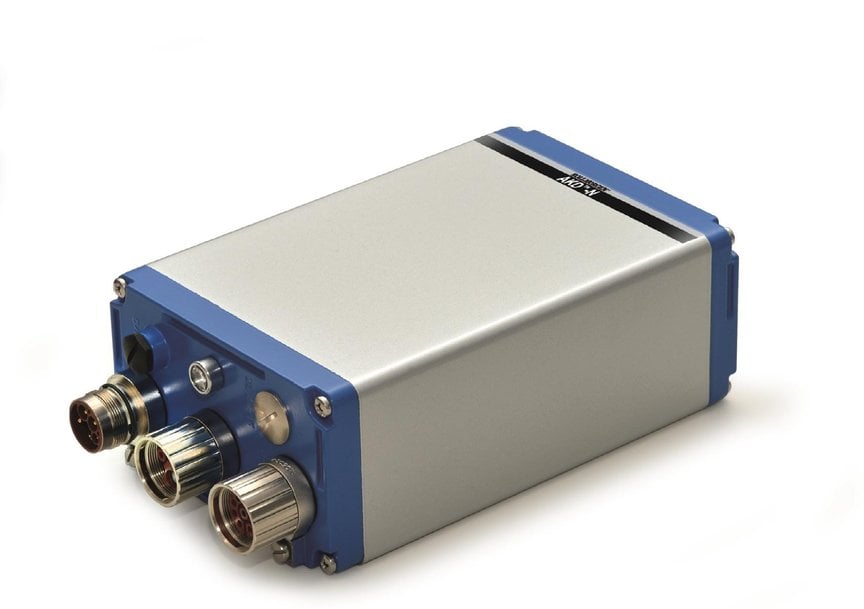

2. Individual AKD-N device

AKD-N distributed servo drive: more robust drive control directly within the process.

3. Servo motor installation

AKM servo motors are compact and quick to install – thanks in part to single-cable connection technology.

4. Bottling demonstration

Rotary indexing tables are used in many filling and packaging processes: now KOLLMORGEN offers a certified safety solution for slip rings for these kinds of applications.

5. Rotary indexing table

Safe Torque Off (STO) in practice: a Swiss manufacturer of test equipment is already using the TÜV-certified safety technology based on a slip ring and AKD-N servo drives from KOLLMORGEN arranged in a distributed setup.

6. STO

Safe Torque Off (STO) is increasingly becoming the norm in the field of drive technology.

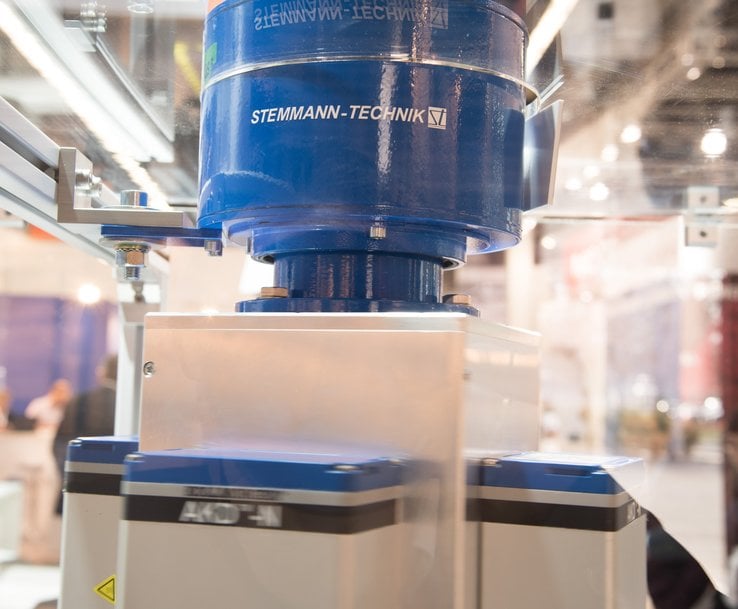

7. Stemmann-Technik slip ring

The safety solution, certified by TÜV Süd, is based on a slip ring from Stemmann-Technik.

8. Author: Felix Haunschild, Safety Development, Kollmorgen Europe, Ratingen