www.magazine-industry-usa.com

08

'09

Written on Modified on

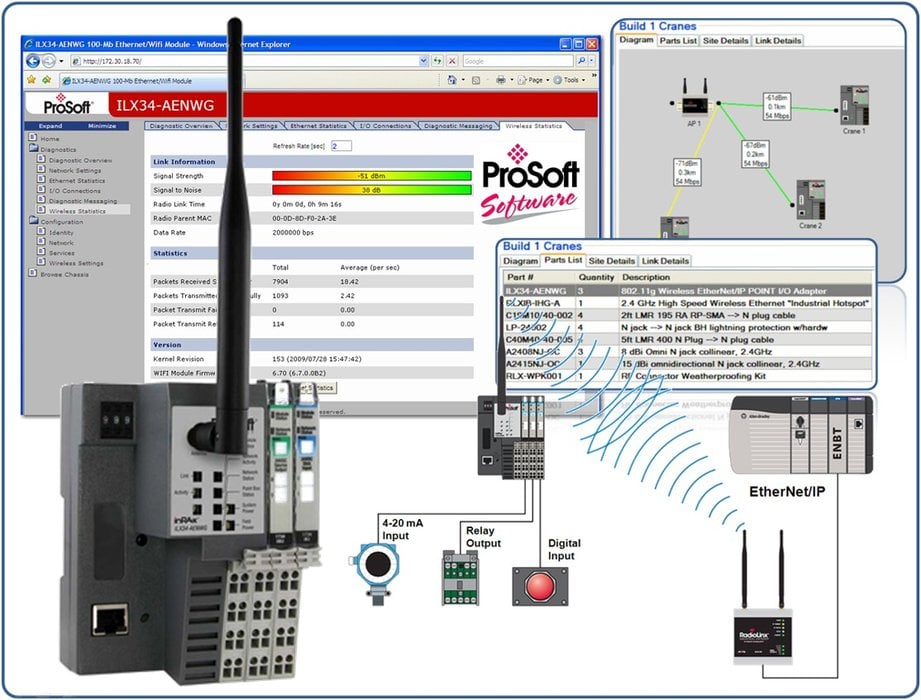

Wireless POINT I/O ILX34-AENWG

ProSoft Technology develops the new Wireless POINT I/O modules for distributed automation applications

The new Wireless POINT I/O Adapter (ILX34-AENWG) is a high-speed, standards-based 802.11g wireless I/O adapter. It takes benefits of the compact size of the 1734 POINT I/O systems (distributed Input/Output modules) from PLC/PAC manufacturer Rockwell Automation®, and combines it with ProSoft Technology’s Integrated Wireless ArchitectureTM.

When coupled with the Wireless, POINT I/O Adapter becomes ideal for collecting data from and for controlling moving systems (like robots, automated carts, overhead cranes, earthmovers), as well as fixed-position racks in hard-to-reach areas of the process plant.

The need

Non-tethered link to distributed I/O is requested in applications with moving or remote equipment, or where it would be difficult or costly to wire devices or control panels. These applications include:

- Tank farms (Oil and Gas, Water treatment),

- Cranes, stackers/reclaimers (Material Handling),

- Rotating filling, spooling, molding machines (Food and Beverage),

- Robotics / multi-axis machining

- Remote monitoring

- Condition monitoring

- and other remote/moving distributed I/O applications.

The solution

The ability to connect POINT I/O modules wirelessly, allows Automation Engineers to design high-performance, scalable and low-latency systems in cases where wired I/O would be problematic.

The Wireless POINT I/O Adapter provides a familiar programming environment to users by utilizing the connection-based EtherNet/IP protocol and configuration with RSLogixTM 5000 programming environment and connection-based EtherNet/IPTM protocol to simplify configuring and communicating with POINT I/O racks scattered throughout the process facility.

The benefits

The Wireless POINT I/O Adapter can be used in networks with RadioLinx® Industrial Hotspots or third party 802.11g access points to provide high-speed, low latency 802.11g client communication over widely spaced plant areas. This ability to work with existing standards-based wireless technology protects and leverages the end-users' investment. For security, the Wireless POINT I/O employs 802.11i WPA2 with AES Encryption.

The Wireless POINT I/O Adapter provides users with the flexibility and scalability (up to 63 modules) offered by the many standard Rockwell Automation POINT I/O modules including analog I/O, digital I/O, POINT Guard I/O(TM), DeviceLogix(TM), relays, RTD, and counters.

All ProSoft Technology products come with a 3 year warranty and unlimited technical support.

When coupled with the Wireless, POINT I/O Adapter becomes ideal for collecting data from and for controlling moving systems (like robots, automated carts, overhead cranes, earthmovers), as well as fixed-position racks in hard-to-reach areas of the process plant.

The need

Non-tethered link to distributed I/O is requested in applications with moving or remote equipment, or where it would be difficult or costly to wire devices or control panels. These applications include:

- Tank farms (Oil and Gas, Water treatment),

- Cranes, stackers/reclaimers (Material Handling),

- Rotating filling, spooling, molding machines (Food and Beverage),

- Robotics / multi-axis machining

- Remote monitoring

- Condition monitoring

- and other remote/moving distributed I/O applications.

The solution

The ability to connect POINT I/O modules wirelessly, allows Automation Engineers to design high-performance, scalable and low-latency systems in cases where wired I/O would be problematic.

The Wireless POINT I/O Adapter provides a familiar programming environment to users by utilizing the connection-based EtherNet/IP protocol and configuration with RSLogixTM 5000 programming environment and connection-based EtherNet/IPTM protocol to simplify configuring and communicating with POINT I/O racks scattered throughout the process facility.

The benefits

The Wireless POINT I/O Adapter can be used in networks with RadioLinx® Industrial Hotspots or third party 802.11g access points to provide high-speed, low latency 802.11g client communication over widely spaced plant areas. This ability to work with existing standards-based wireless technology protects and leverages the end-users' investment. For security, the Wireless POINT I/O employs 802.11i WPA2 with AES Encryption.

The Wireless POINT I/O Adapter provides users with the flexibility and scalability (up to 63 modules) offered by the many standard Rockwell Automation POINT I/O modules including analog I/O, digital I/O, POINT Guard I/O(TM), DeviceLogix(TM), relays, RTD, and counters.

All ProSoft Technology products come with a 3 year warranty and unlimited technical support.