www.magazine-industry-usa.com

11

'09

Written on Modified on

CoverTrax 1555

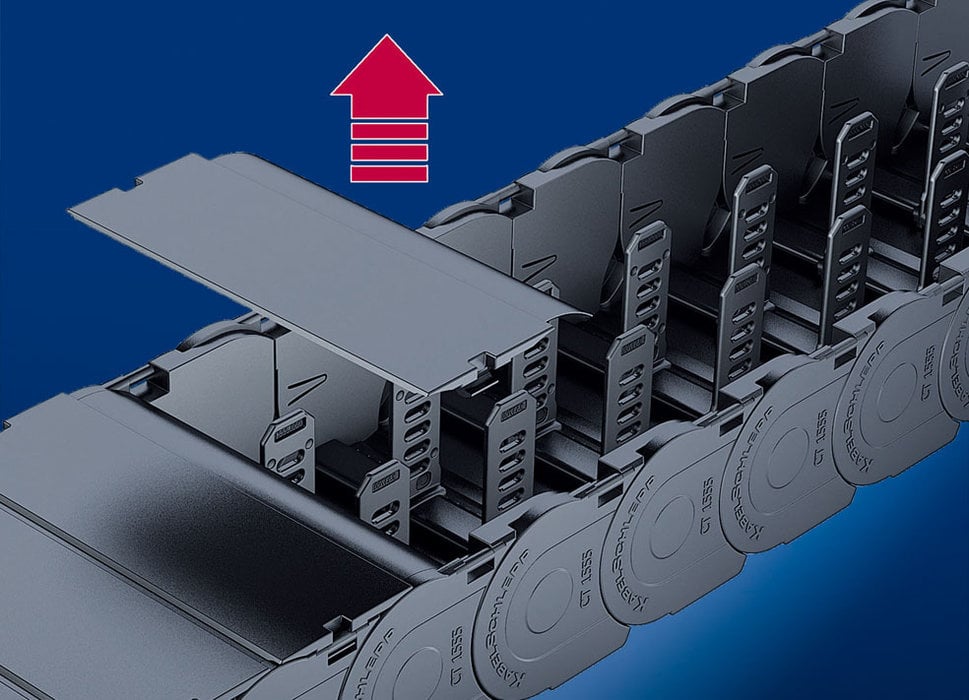

The CoverTrax 1555 from KABELSCHLEPP was developed specifically for harsh environments. This covered cable carrier provides effective protection against metal chips, dust and dirt, and prevents foreign objects from entering the cable space.

This is made possible by an optimised geometry and a reinforced cover contour that permits ex-tremely small gap dimensions even with large carrier widths. As a result, foreign matter can nei-ther become wedged in the gaps nor penetrate into the inside of the carrier while it is in motion. Since the cover is flush with the sideband, dirt is diverted to the sides. The overall design of CoverTrax ensures that foreign matter, dust and dirt have few opportunities to reach the inside of the carrier. Additional convincing features of the CoverTrax 1555 design include the smooth con-tour of the sideband and the extremely quiet operation resulting from the encapsulated stroke sys-tem.

CoverTrax even meets the requirement to remain tightly sealed close to the connection point, since it features cover systems both inside and outside here. Thus, with front connection, a com-pletely enclosed variant is possible.

The new hinge mechanism offers further benefits for flexible and equally uncomplicated use of CoverTrax. It allows the cover to be opened easily and quickly both inside (Type 60) and outside (Type 080), and detached completely. The CoverTrax is similarly easy to handle and flexible when it comes to the dividers, which can be positioned across the carrier cross section, but also fixed in place by simply turning and locking. This innovation from KABELSCHLEPP is designed for both self-supported (gliding) and unsupported installation – here, also for very long unsupported lengths – and very quiet during operation thanks to the internal damping. Using the UMB universal mounting brackets, it can be attached from the outside, the inside or from the front. A strain relief comb, C-rails and LineFix bracket clamps are optionally available to provide strain relief for the cables. The UMB universal brackets have mounts above and below for attaching a C-rail or strain relief comb.

Applications: off-highway vehicules, mining, oil rigs, machine-tools, woodworking...

CoverTrax even meets the requirement to remain tightly sealed close to the connection point, since it features cover systems both inside and outside here. Thus, with front connection, a com-pletely enclosed variant is possible.

The new hinge mechanism offers further benefits for flexible and equally uncomplicated use of CoverTrax. It allows the cover to be opened easily and quickly both inside (Type 60) and outside (Type 080), and detached completely. The CoverTrax is similarly easy to handle and flexible when it comes to the dividers, which can be positioned across the carrier cross section, but also fixed in place by simply turning and locking. This innovation from KABELSCHLEPP is designed for both self-supported (gliding) and unsupported installation – here, also for very long unsupported lengths – and very quiet during operation thanks to the internal damping. Using the UMB universal mounting brackets, it can be attached from the outside, the inside or from the front. A strain relief comb, C-rails and LineFix bracket clamps are optionally available to provide strain relief for the cables. The UMB universal brackets have mounts above and below for attaching a C-rail or strain relief comb.

Applications: off-highway vehicules, mining, oil rigs, machine-tools, woodworking...