www.magazine-industry-usa.com

26

'17

Written on Modified on

These small

scale ball screw drives work hard, so webs can stay on course.

One of the leading developers and manufacturers of web guiding systems has recognised the advantages of using cold-rolled ball screw drives (BSGs) from Eichenberger Gewinde AG. He has put his trust in the expertise and flexibility of the thread rolling specialist from Burg, Switzerland and is now one of their regular customers.

To try to achieve dynamic balance, a web usually tends to align itself at right angles to the guide rolls. Various factors such as strength, stress distribution and inertia come into play. Processors form the heart of the electronic control system.

Processor units in combination with multiple highly-accurate sensors and free-running drives form an extremely accurate control system with high dynamics in the moving web.

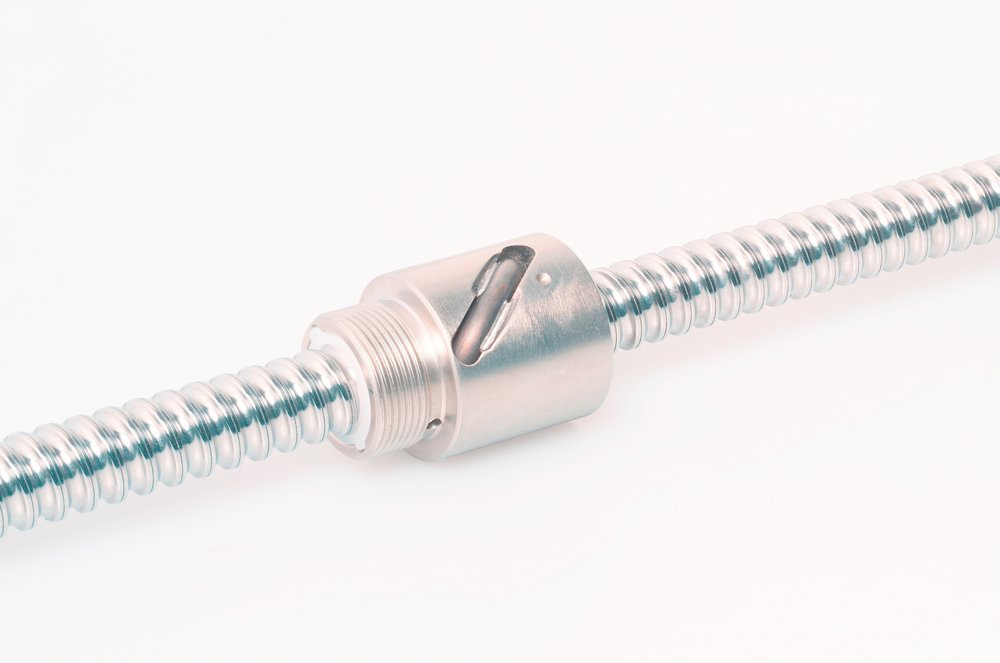

Various pivoting frame systems allow highly accurate corrections to be made by guiding the web at a different angle when it goes through the control loop. The rotation of the frame transfers the web to the position required for the process. Approximately 10 different types of ball screw drives are used in the various systems, each of which is perfectly suited to its task. These include special customer-specific BSDs or FGR, ZYI series types, in sizes ranging from Ø 8 mm, 1 mm lead (8 x 1) to Ø 32 mm, 5 mm lead (32 x 5). These cold-rolled BSDs carry out accurate movements, in some cases in a very limited space.

Small functions that produce a big effect

A spindle is controlled directly via a motor, a gear and a belt transmission. These cause rotational movements to be transformed into linear movements. In the case of web guiding systems, the ball screw drive starts the correction movement of the sensor-controlled actuator.

Thrust, speed, torque and accuracy are thus integrated into a single device, allowing perfect control of the optimisation of the web's position, with the help of pivoting frames or other systems. The benefits of cold-rolled ball screw drives are, among other things, their high efficiency (over η 0.9) and the resulting energy savings. Using force transmission with balls, the required actuating power can be reduced by approximately two thirds.

Eichenberger Gewinde AG has the resources to be exceptionally flexible, due to the expertise they have built up over six decades and the advantage of keeping development, production and quality assurance in a single location. This in turn, makes it possible to accelerate the production of prototypes and deliver them within very short lead times. Even the rolling tools can be manufactured in-house. Thanks to these factors, and by using advanced machinery, it is possible to manufacture flexibly and competitively even in a high-cost location. The thread-rolling specialist, Eichenberger Gewinde AG delivers tailored solutions that provide optimal functionality, maximum energy efficiency, and are cost-effective as well.