www.magazine-industry-usa.com

19

'26

Written on Modified on

Northrop Grumman expands defense manufacturing & R&D operations in Maryland

In Maryland, Northrop Grumman manufactures propulsion systems, microelectronics, sensors, undersea vehicles and space hardware supporting defense, aerospace, and national security programs.

www.northropgrumman.com

Northrop Grumman operates an extensive network of manufacturing and research facilities across Maryland, forming a core part of the company’s U.S.-based defense and aerospace production footprint. The sites support propulsion, electronics, sensor systems, undersea platforms, and space technologies used across air, land, sea, and space domains.

The Maryland operations span more than 30 facilities with over six million square feet of manufacturing space, located near major U.S. military and research hubs including Naval Air Station Patuxent River and Aberdeen Proving Ground. Together, these sites combine vertically integrated manufacturing, testing, and qualification capabilities designed to shorten development cycles and support long-term production programs.

Propulsion manufacturing for hypersonic and missile systems

In Elkton, Maryland, the Hypersonics Capability Center produces propulsion technologies for hypersonic systems operating at speeds beyond Mach 5. The facility applies digital engineering, consolidated production workflows, and scaled manufacturing methods to support air-breathing hypersonic propulsion.

Adjacent investments include the 57,000-square-foot Propulsion Innovation Center, part of a broader $100 million expansion in Elkton focused on hypersonic and solid rocket motor production. Over the past seven years, Northrop Grumman has invested more than $1 billion across its operations to increase capacity for missile propulsion and critical components.

Elkton facilities also support the design and testing of solid rocket motors such as the 21-inch second-stage motor and the Mk 72 prototype for U.S. Navy applications. These programs integrate digital twins and performance modeling validated against measured test data, with multiple qualified suppliers used to reduce supply chain risk.

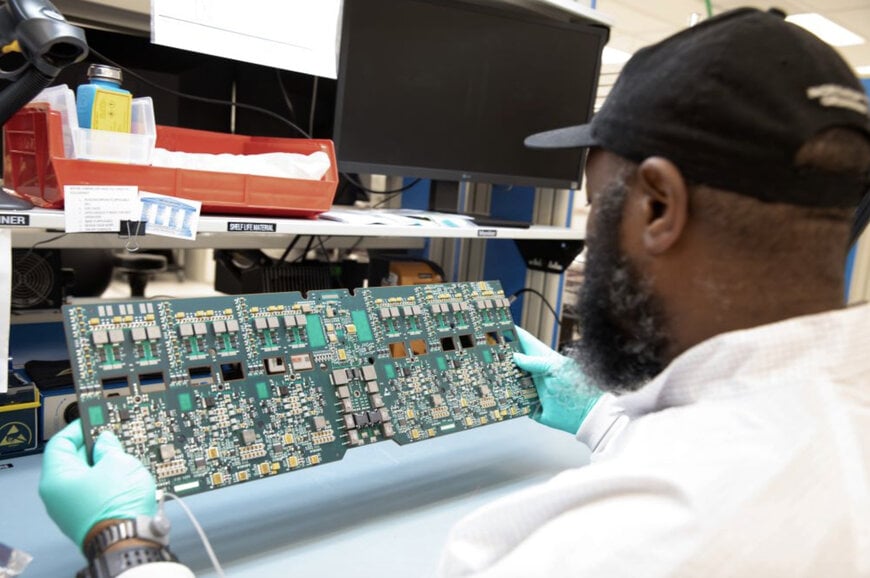

U.S.-based microelectronics manufacturing

Microelectronics production is centered around Northrop Grumman’s government-accredited fabrication facilities in Maryland, including the Advanced Technology Lab near Baltimore. The site provides over 111,000 square feet of cleanroom space and supports the full semiconductor lifecycle, from design and fabrication to packaging and long-term sustainment.

The facility manufactures high-reliability chips used in defense, aerospace, and select commercial systems, with product lifecycles extending over multiple decades. All manufacturing is performed within the United States, supporting supply chain security and compliance requirements for national security programs. Access to these facilities is also provided to partners across the defense industrial base.

Defense electronics and multispectral sensors

At the Linthicum campus, Northrop Grumman designs and manufactures defense electronics across more than 20 buildings. The site supports vertically integrated production, from semiconductor foundry processes through final system testing.

The facility specializes in multispectral sensing technologies, including radar and radio-frequency systems designed for long-range detection in constrained size, weight, and power envelopes. Systems produced here operate in harsh environments and support both crewed and uncrewed platforms.

In Baltimore, the company builds multifunction sensors for ground and airborne applications. These systems combine advanced electronics with software-defined architectures to support target detection, tracking, and situational awareness. Programs include active electronically scanned array radars and mobile ground/air surveillance systems used across multiple operational domains.

Undersea and space systems production

Northrop Grumman’s Annapolis facility focuses on undersea technologies, including autonomous unmanned underwater vehicles. Platforms such as Manta Ray are designed for long-duration missions with extended range and payload capacity. The site also develops precision underwater sensing systems used for seabed imaging and situational awareness in deep-water environments.

Maryland facilities also manufacture space avionics and thermal control hardware supporting civil, commercial, and defense space missions. These products have been used in satellite systems for climate monitoring, communications, and space exploration for more than six decades, with emphasis on high reliability and single-point-failure mitigation.

Industrial scale and workforce impact

Across Maryland, Northrop Grumman employs more than 14,000 people and supports tens of thousands of additional jobs through its supply chain. The sites combine manufacturing scale with integrated testing and qualification infrastructure to support sustained production of complex defense and aerospace systems.

The Maryland operations illustrate how propulsion, electronics, sensing, undersea, and space technologies are developed and produced within a single regional industrial ecosystem, supporting long-term defense and national security requirements.

www.northropgrumman.com