www.magazine-industry-usa.com

19

'25

Written on Modified on

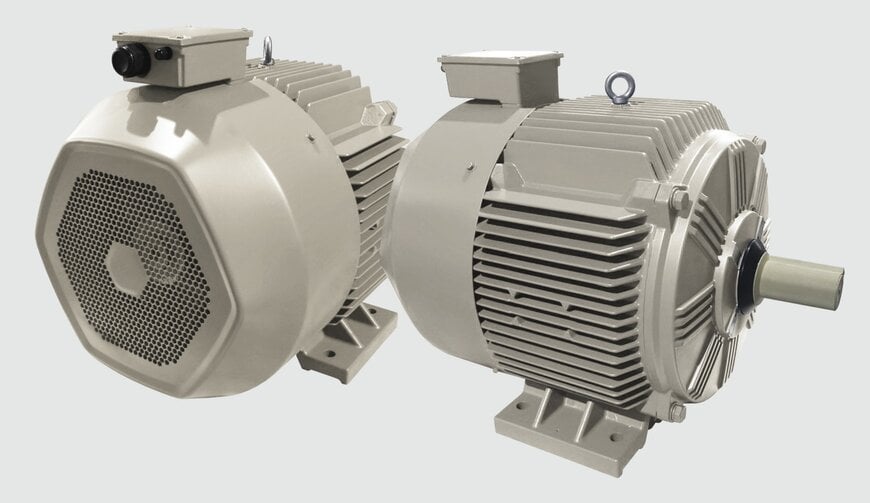

Direct Drive Motors for Industrial Airflow Efficiency

Wolong Electric America outlined how permanent magnet motor architectures reduce mechanical losses and lifecycle costs in fan and air-handling applications.

www.wolongamerica.com

Wolong Electric America highlighted its permanent magnet direct drive (PMDD) motors as an alternative to conventional belt-driven and induction motor configurations used in industrial airflow applications. The motors are intended for systems such as fans, blowers, and air-handling equipment operating in environments where energy efficiency, uptime, and maintenance access are critical.

Removing mechanical losses from airflow systems

PMDD motors use a direct drive architecture that eliminates belts and sheaves, removing common sources of mechanical loss and wear. By coupling the motor directly to the fan, the design reduces system complexity and avoids alignment issues and belt degradation that typically contribute to unplanned maintenance. The absence of belt-driven transmission also lowers radial loads on bearings, reducing mechanical stress and extending service intervals.

The motor design incorporates a rare-earth permanent magnet rotor, which produces higher magnetic flux density than ferrite-based designs. This enables a more compact motor footprint while maintaining torque output and improving electrical efficiency compared with traditional induction motors.

Variable-speed operation under real load conditions

Operation is managed through a variable frequency drive (VFD), allowing precise speed control and smooth acceleration and deceleration. This approach limits energy spikes during startup and supports stable operation under fluctuating airflow demand. A specified 4:1 turndown ratio allows the motors to maintain usable torque and efficiency at reduced speeds, supporting applications that require frequent modulation rather than constant full-load operation.

For airflow systems subject to variable ambient conditions or process-driven demand changes, this controllability enables closer matching of motor output to actual load, improving overall system efficiency.

Measurable efficiency and electrical performance gains

According to Wolong Electric America, PMDD motors achieve approximately 20% higher efficiency than comparable induction motors in airflow applications. Direct drive operation also enables smoother starts without inrush current, reducing electrical stress on upstream infrastructure and connected equipment. Lower heat generation during operation contributes to cooler running temperatures, which supports longer insulation life and improved long-term reliability.

These electrical and thermal characteristics are particularly relevant in large-scale installations where repeated starts, continuous operation, or sensitive power networks amplify the impact of inefficiencies.

Application flexibility and system integration

The motors are designed for integration into a range of industrial environments, including data centers, refineries, and OEM-built equipment such as heat exchangers. Wolong Electric America offers application-specific configurations to align motor characteristics with system requirements, supporting easier integration into OEM and packager designs.

By reducing maintenance demands and extending service life, the PMDD platform also supports streamlined service planning and reduced downtime, contributing to lower total cost of ownership over the operating life of airflow systems.

Alignment with evolving efficiency requirements

The PMDD motor architecture is positioned to meet increasingly stringent energy efficiency expectations, including anticipated Department of Energy efficiency standards. For operators upgrading legacy equipment or designing new airflow systems, the combination of direct drive mechanics, permanent magnet efficiency, and VFD control provides a pathway to improved performance while maintaining regulatory compliance.

In industrial settings where airflow reliability and energy consumption directly affect operating costs, permanent magnet direct drive motors represent a shift away from mechanically complex drive systems toward electrically efficient, low-maintenance alternatives.

www.wolongamerica.com