University of Sheffield Develops 3D Liquid Surface Measurement Technique

University of Sheffield researchers develop 3D stereoscopic measurement method using Mikrotron EoSens CXP cameras, 1080p projector, and Digital Image Correlation for liquid surface dynamics.

mikrotron.de

Measurement of liquid-free surfaces is fundamentally important in applications subject to liquid sloshing, wave propagation, or fill-level transients. For instance, in chemical, petroleum, and water treatment industries, monitoring the free surface level in storage tanks ensures accurate inventory management, prevents overflows, and maintains operational safety. In pipelines transporting liquids, free surface measurements help detect flow regimes and ensure efficient operation. And in medical systems like dialysis machines or IV drips, monitoring the free surface of liquids ensures accurate dosing and patient safety.

Advancements in sensor technology have enabled robust 2D measurement techniques for tracking free surface dynamics in partially filled pipelines, tanks, and containers. However, monitoring these dynamics in 3D is very limited. Until recently, in fact, there has been no studies on surface 3D measurement in partially filled pipes due to its geometry complexity.

NOVEL 3D TECHNIQUE

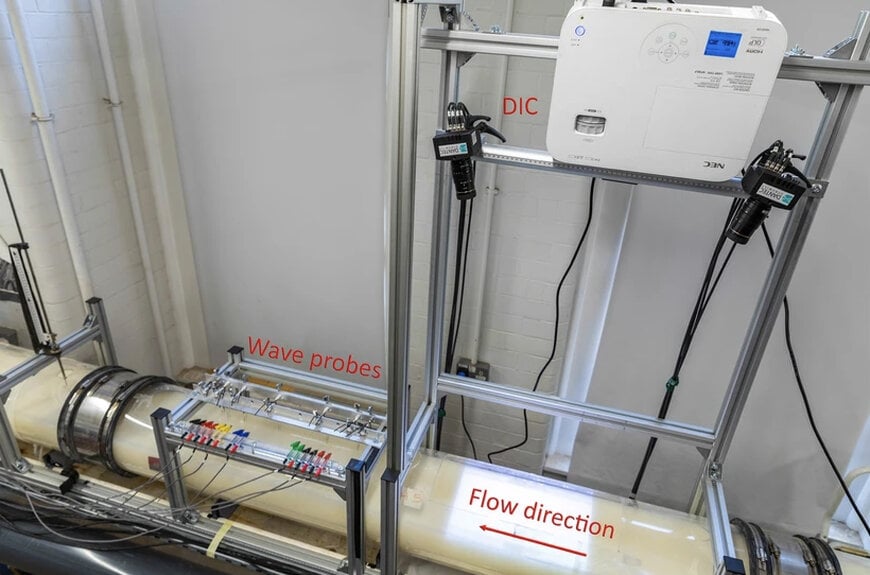

Researchers at the University of Sheffield (Sheffield, UK) recently took up the challenge of developing a novel 3D stereoscopic method for free surface measurement. They demonstrated that the parameters of turbulent flow in partially filled pipes, including surface fluctuations and surface velocity, could be measured with a technique consisting of a high-resolution projector, two Mikrotron CMOS cameras, and a standard Digital Image Correlation (DIC) algorithm.

Mikrotron EoSens 4CXP high-speed CMOS cameras are part of the stereoscopic DIC system (photo courtesy of University of Sheffield)

Observations were carried out in a 300mm diameter transparent plastic pipe that was 20 meters long and slightly sloped. An adjustable butterfly valve located upstream of an inlet tank regulated the pump's discharge. Tinting the water inside the pipe white with titanium dioxide made its surface appear solid to the image-based measuring system. A five-megapixel stochastic pattern of light was projected onto the tinted water surface by a NEC 1080p projector that was mounted above the pipe. Patterns were captured on the deformed water surface by the two Mikrotron cameras installed just below the projector at fixed 40° angles. In addition to the cameras, seven pairs of wave probe arrays were used for measurement verification.

The dual Mikrotron EoSens CXP 4-megapixel monochrome cameras were configured at their maximum resolution of 2336 x 1728 pixels and a frame rate of 563 fps. A round bar supported both cameras, allowing for adjustment of the angle and distance between them. Sampling frequency was set to 120 Hz to synchronize with the HD projector running at 60 Hz.

A total of fourteen flows were recorded for five minutes each with their magnitude determined using an electromagnetic flow meter. Water depth was controlled to ensure uniform conditions throughout the measurement and for the stability of the flow. Once raw images were captured of each flow, they were transmitted to a PC via the cameras' CoaXPress interface capable of 25 Gbit/s data transfer for real-time streaming. Following image pre-processed with Instra4D software, the 3D instantaneous water surface fluctuations were able to be computed leveraging the DIC algorithm.

The University of Sheffield research team reported that the power spectrum and standard deviation of the measured data from the cameras and the wave probes were comparable. These results validated their novel technique's ability to measure free surface dynamics at multiple locations on a surface with the accuracy of a 2D system while offering the advantages of 3D reconstruction of the full surface geometry.

www.mikrotron.com