Meltio launches its first advanced additive manufacturing site in the United States

Meltio and Fastech inaugurate their first advanced additive manufacturing site in Danville, Virginia, showcasing groundbreaking Blue Laser wire-laser 3D printing technology for multiple industries on October 14, 2025.

www.meltio3d.com

Meltio and Fastech has announced the official launch of its introduction from the infrared-laser–based Meltio Engine Robot Integration to Blue Laser wire metal 3D printing technology.

This milestone will be celebrated with the opening of Meltio’s first international Advanced Additive Manufacturing (AM) reference site in Danville, Virginia, on October 14, 2025. Join us for this inaugural gathering, where the new facility will serve as a demonstration hub for U.S. and international industries to experience the capabilities of Meltio’s Directed Energy Deposition (DED) wire-laser metal 3D printing solutions across multiple sectors.

This site marks a major milestone in Meltio’s global expansion, highlighting the breakthrough shift from IR to Blue Laser technology. With greater performance, reliability, and scalability, this introduction sets the stage for future reference centers worldwide.

The new Meltio Reference Site will specialize in producing metal parts for sectors such as defense, aerospace, naval, education, and beyond. It highlights the value of wire-laser metal additive manufacturing in solving critical challenges: enabling on-demand repair and production in remote or operational areas, replacing obsolete or worn-out components, restoring battle-damaged equipment, and providing design flexibility for innovative parts. By reducing reliance on vulnerable supply chains and allowing remote tele-operation, Meltio delivers shorter time to part and reduced costs.

As part of this milestone, Fastech has acquired the Meltio M600 metal 3D printer and the Meltio Robot Cell, which will be fully operational and on display during the open house, showcasing Meltio’s industrial metal additive manufacturing solutions.

Advancing the Defense and Security sector: A New Era for the American industry

Meltio’s reference site will enable manufacturers across the defense, aerospace, automotive, mining, energy, oil and gas, and research sectors to test, validate, and adopt metal AM applications. Thanks to the capabilities of Advanced Additive Manufacturing that Meltio offers, the center will help companies cut costs, speed up production, and strengthen supply chains with reliable, on-demand manufacturing.

The Meltio M600 industrial system and the Meltio Engine Integration Kit for industrial robots enable the production and repair of parts in multiple materials, including copper, titanium, stainless steel, Inconel, and aluminum.

Competitive Advantages

Meltio addresses evolving demands across multiple American industries by delivering highly reliable metal 3D printing making possible Advanced Additive manufacturing through its Blue Laser technology, offering exceptional versatility in part production, repair, durability, and feature addition. Its near-net shape approach minimizes production time and reduces material waste, making the process more environmentally friendly, setting a new standard for efficiency in additive manufacturing.

Meltio’s wire-laser Directed Energy Deposition (DED) metal additive manufacturing solutions offer higher tolerances and superior part definition compared to other similar technologies. This makes it particularly valuable for industries where precision, repeatability, and reduced lead times are critical.

Alan Pearce, CEO of Fastech, said: “We are proud to partner with Meltio to bring this groundbreaking reference site to life. Many companies, including ours, are embracing DED technology because it enables higher tolerances, superior part definition, precision, repeatability, readiness, and reduced lead times. This site will give U.S. manufacturers the chance to experience those advantages firsthand.”

Gabriel Ortiz, Sales Manager, Meltio in the United States, added: “Establishing this first global reference site in the United States reflects Meltio’s strong commitment to supporting U.S. industries. With Fastech, we are giving manufacturers the opportunity to explore cutting-edge applications, from defense to research, that demonstrate the transformative power of wire-laser metal 3D printing.”

Meltio Engine Blue & multi-laser Blue Deposition Head, a reliable industrial solution

The Meltio Engine Blue enhances Meltio’s metal AM solutions with increased reliability, power, and versatility using Blue Laser technology. It can print stainless steel, titanium, copper, aluminum, nickel, and other metals, producing parts with high density, precision, and repeatability for a wide range of industrial applications.

“The new Meltio Engine Blue is a breakthrough in our directed energy deposition (DED) technology, designed to meet the evolving demands of manufacturing worldwide,” says Meltio Product Manager Alejandro Nieto. “It delivers higher reliability and deposition rates, enabling faster production and superior quality. With a fiber-optic-free 1.4 kW blue laser head, integration into robotic arms and vertical machining centers is simpler, maintenance is reduced, and issues like continuous laser alignment are eliminated. This allows our customers to optimize processes, reduce downtime, and work with a broader range of materials.”

Its ease of integration and high reliability make the Meltio Engine Blue a standout solution for industrial sectors, including automotive, aerospace, energy, naval, defense, mining, and oil & gas.

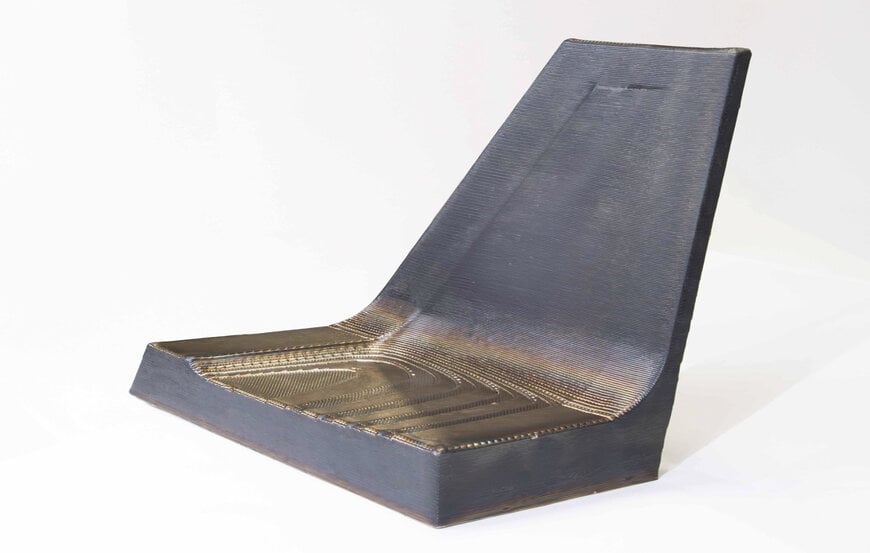

Metal parts on display at Fastech’s new Reference Site during the Open House:

- Artillery Shell: Defense sector application developed by Meltio on the Meltio M600. Manufactured in SS-316LSi and Marine Bronze, it demonstrates the potential of multi-material additive manufacturing for critical defense components.

- Dual Wall Pipe: Oil & Gas sector application developed by Meltio. Produced in SS-316LSi with the Meltio Engine Robot, this part demonstrates the potential of additive manufacturing for high-strength and corrosion-resistant components in demanding energy environments.

- Engine Block: Automotive sector application developed by Polimotor. Manufactured in SS-316LSi using Meltio Engine Robot, this part showcases the potential of additive manufacturing for complex and high-performance automotive components.

- Flap Actuator: Aerospace sector application developed by Meltio. Manufactured in Titanium 64 on the Meltio M600, this component weighs only 0.67 kg, showcasing the advantages of lightweight, high-strength additive manufacturing for aerospace systems.

- Lightweight Tank Ice Cleats: Defense sector Case Study developed by Meltio with AM Solutions for the K2 Black Panther tank. Produced on the Meltio M600, these parts achieve 60% weight reduction, enhance soldier mobility, and reduce lifecycle costs, showcasing the advantages of additive manufacturing for tactical applications.

- Winglet Mould: Aerospace sector Case Study developed by CATEC in collaboration with Meltio. Manufactured in Invar using the Meltio Engine Robot, this part demonstrates high precision and thermal stability, highlighting the potential of wire-laser DED technology for the production and repair of complex aerospace tooling.

- Propeller Shaft Bracket: Naval sector application developed by Meltio. Manufactured in Marine Bronze on the Meltio M600, this part demonstrates the strength, corrosion resistance, and precision achievable with additive manufacturing for demanding maritime components.

- Jet Engine Exhaust: Aerospace sector application developed by Meltio. Manufactured in SS-316LSi using the Meltio Engine Robot, this part showcases the durability and high-temperature performance achievable with additive manufacturing for critical aerospace components.

Discover how Meltio’s Blue Laser wire-laser metal 3D printing technology can help your business reduce costs, accelerate production, and unlock new design possibilities.

Registration form to attend the Open House here.

www.meltio3d.com