Progressive Cavity Pumps: Driving Efficiency and Reliability in Global Mining

SEEPEX solutions handle abrasive slurries, flocculants, and dewatering with ease — cutting energy use, reducing downtime, and supporting sustainable operations worldwide.

www.seepex.com

The mining and metals industry plays a critical role in supporting global progress. From consumer electronics and agriculture to infrastructure and transportation, modern society depends on a secure and sustainable supply of minerals. This dependence is growing as the world accelerates toward an energy transition, requiring large volumes of critical raw materials such as copper, lithium, and rare earth elements.

Mining companies worldwide are under increasing pressure to balance rising demand with sustainability goals. Operators are adopting low-carbon technologies, seeking financing linked to environmental performance, and strengthening collaboration with downstream partners to meet customer expectations for responsibly produced materials. At the same time, they face persistent challenges such as volatile commodity prices, water scarcity, labor shortages, and stricter regulations on safety and environmental performance. Pumps are one of the many technologies that can help address these challenges by improving efficiency, reducing energy consumption, and enabling safer, more reliable operations.

Expectations in the Mining Industry

The key expectations for mining equipment are cost, performance, and HSE (Health, Safety and Environment). Performance remains the top priority, ensuring reliable outputs and consistent product quality. Yet efficiency must not come at the expense of safety or reliability. Pumps that require less frequent maintenance and can be safely dismantled without complex handling reduce downtime and risks to personnel.

Mining is among the harshest industrial environments, where abrasive, corrosive, and variable conditions demand equipment that is robust and adaptable. Selecting the right pump materials is critical to withstand extreme pH levels, salinity, or high solids content. Equipment that meets these criteria not only extends operating life but also supports the industry’s commitment to responsible resource use.

An Omnipresent Factor: Mine Dewatering

Water management is a universal challenge in mining. Water may be added intentionally during ore washing or processing, or it may enter naturally as groundwater. Mine dewatering ensures continuous operations by keeping pit floors and underground workings dry, reducing the risk of flooding or slope instability, and enabling safe working conditions.

Efficient dewatering systems are also crucial for meeting regulatory requirements and minimizing environmental impacts. Pumps capable of handling variable flow rates and solids content are essential to ensure stable, cost-effective water management.

Main Applications for Progressive Cavity Pumps in Mining

SEEPEX progressive cavity (PC) pumps are proven in diverse mining environments around the world. Their ability to handle abrasive, viscous, and shear-sensitive media makes them suitable for a wide range of applications:

- Flocculants: The low-shear pumping principle preserves flocculants during thickening processes.

- Thickener underflow: reliable and cost-effective transfer of concentrates and abrasive tailings.

- Reagent dosing: Precise metering of flotation reagents such as PAX, GUAR, and MIBC.

- Mine dewatering: High-pressure capability supports continuous underground and surface operations.

- Filter press feeding: Smooth, low-pulsation delivery improves efficiency in solid-liquid separation.

- Explosives emulsions: Safe, controlled transfer of viscous explosives for rock blasting.

- Camp wastewater: Supporting environmental management in remote mining communities.

Energy Savings with SEEPEX

Mining is energy-intensive, and pumps are often overlooked as a source of potential savings. SEEPEX PC pumps are specifically designed for efficient transfer of abrasive, corrosive, or shear-sensitive materials with minimal wear. Operating at low speeds and with a clear flow passage, they ensure smooth, low-shear handling while reducing energy demand.

Key advantages include:

- Lower installed power compared to alternative pump types.

- No gland seal water required, eliminating additional costs and infrastructure.

- Constant flow regardless of backpressure or solids content, ensuring stable operation.

- Flexible operation, as PC pumps perform effectively at any point on the curve with no BEP limitations.

- Reduced life cycle costs, as both energy and water consumption are significantly lower.

With their easy maintenance features, SEEPEX pumps minimize downtime, enable safer handling, and extend service life. They can be installed on simple baseplates or engineered skids that integrate control systems and safety features for complete solutions.

Why Choose SEEPEX?

SEEPEX delivers solutions that meet the demanding requirements of global mining operations. Their pumps combine robust performance with efficiency, ensuring reliable handling of mineral slurries, corrosive media, and sensitive reagents. With a wide range of materials available, SEEPEX ensures compatibility with harsh mining conditions while preserving the integrity of sensitive media such as flocculants.

Backed by global engineering expertise, EPCM support, and a worldwide service network, SEEPEX partners with mining operators to improve productivity, lower costs, and support a sustainable future.

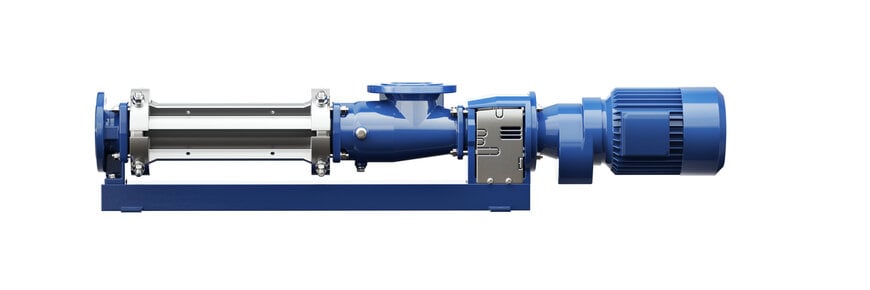

SEEPEX SCT pumps gently handle flocculants, extend stator life by 200%, and ensure easy maintenance.

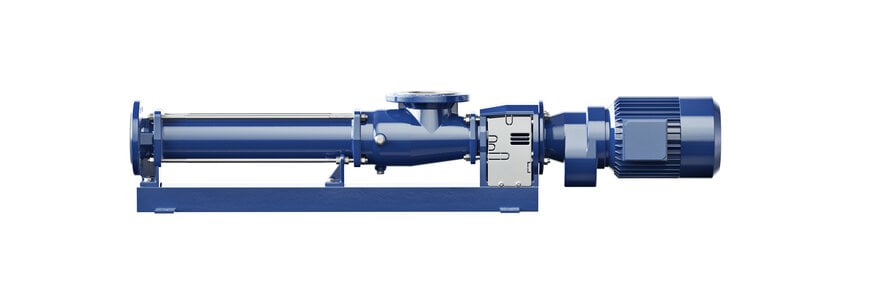

SEEPEX BN pumps adapt to pressure and solids variations, handling both low- and high-solid slurries reliably and easily.

Mines will face water issues at some point during their operation, and it is a frequent problem.

PC pumps can aid in wastewater management for remote mining camps that house the mining crews, too.

SEEPEX mining pumps help reduce operating costs not only at mining sites but also in mineral processing plants.

Massive open pit mines are masterpieces of environmental engineering.

www.seepex.com