Are We Really Done With IC Engines?

It is more than likely that future mobility will be characterised by a mix of solutions rather than any single panacea.

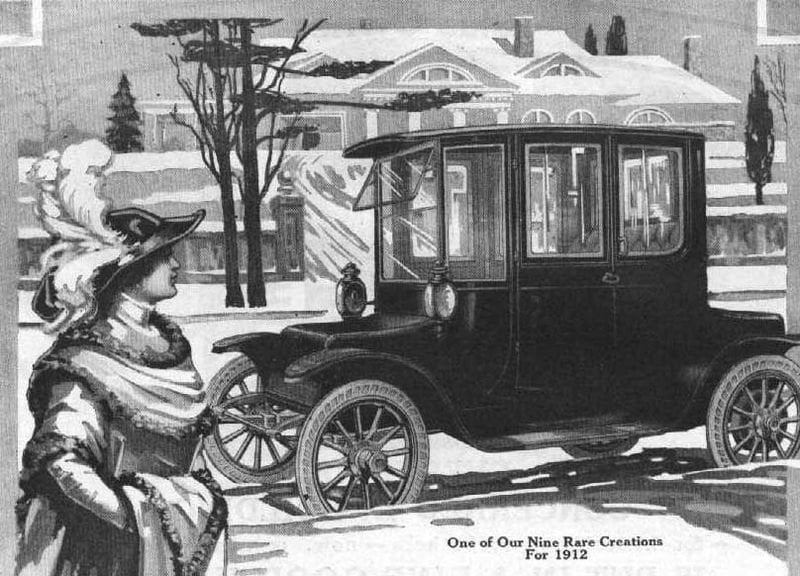

An advertisement for the 1912 Detroit Electric car. Source: Wikimedia Commons

In the beginning there was the electric car. Strange as it may appear to many of today’s generation, the history of the automobile actually began with the electric car. According to the website of the US Energy Department, the first electric car was developed in 1832, much before the invention of the internal combustion (IC or gasoline/petrol engine) or the compression ignition (CI or diesel engine) cars.

The early electric car developed in 1832 was a crude contraption but by mid-1870s electric cars had evolved into practical carriages, though these were more like horseless buggies than the conventional automobile that evolved later. By the turn of the century, electric cars had become quite popular compared to the gas or steam powered automobiles that were also produced, these being more cumbersome to drive besides being highly polluting.

The early EVs rose to the peak of their popularity during 1900-1912 in the US, accounting for a third of all vehicles plying on American roads. This was the period when even Thomas Alva Edison saw promise in EVs and spent time improving battery capacity, as did other innovators who explored ways and means to improve the overall technology.

The first hybrid car was also developed in Europe by Ferdinand Porsche during this period. But there was another development during around this time that finally put paid to whatever prospects the electric car had to become the predominant mode of transport – the launch and evolution of the Ford Model T. Introduced in 1908, the Ford Model T was one of the few mass produced cars of that era with several refinements and innovations that made it hugely popular. In 1912, the Model T got the electric starter and that effectively sealed the fate of the still evolving electric car!

The 1925 Ford Model T Touring. Photo by ModelTMitch. Source: Wikimedia Commons

The evolution of heat engines

The evolution of the heat engine – any system that converts heat into mechanical energy – began from the early years of human civilisation. One of the earliest examples dates back to the first century CE when the fire piston originated in Southeast Asia. At its very basic, the fire piston comprises a hollow tube sealed at one end in which tinder is placed and a piston with basic sealing mechanism inserted with force from the other end. The compression of air which is caused by the pushing of the cylinder is enough to cause the pressure and temperature to rise and ignite the tinder. This is exactly the basic principle of the diesel engine which was invented much later, during the late 19th century!

The earliest practical heat engine was the steam engine which was in the making for hundreds of years. However the first credible effort was by Jerónimo de Ayanz y Beaumont, a Spanish inventor who received patents in 1606 for 50 steam-powered inventions, including a water pump used for removing water from the mines. The credit for the first commercial steam-powered water pump developed in 1698 though goes to English engineer and inventor Thomas Savery.

In 1712, Thomas Newcomen in England designed a more efficient steam engine with a piston separating the condensing steam from water. But it was James Watt who greatly improved the Newcomen engine around 1764, by adding a separate condenser to avoid heating and cooling the cylinder with each stroke. He later made several improvements and developed a new engine with a rotating shaft rather than the reciprocating movement.

The steam engine – basically the use of boiling water to generate steam that created the mechanical force – is thus considered one of the most important inventions of the Industrial Revolution. By providing the motive power to factories, ships, railways and even the early automobiles, it transformed human lives like no other development until then. Even today, steam turbines are used to propel ships and in power plants to generate electricity.

Even as the steam engine, which is an external combustion engine, was ruling the mobility scene, efforts were gathering steam – no pun intended – in the development of the internal combustion engine, which too was long in the making. In the early 19th century various inventors from the US and Europe registered patents for different types of internal combustion engines. In 1860, for example, Belgian engineer Jean Joseph Etienne Lenoir produced a gas-fired internal combustion engine; but the one invented by American George Brayton in 1872 is widely regarded as the first modern liquid fuelled internal combustion engine.

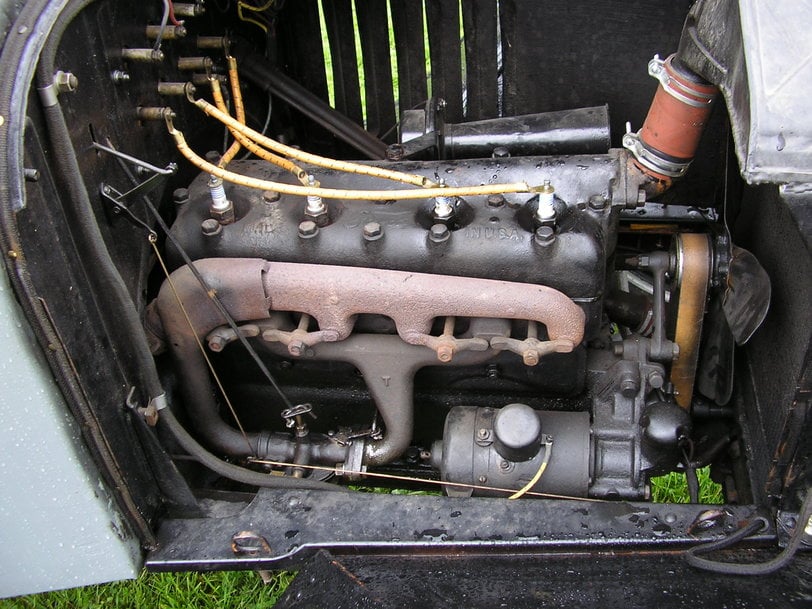

The IC engine in a Ford Model T. Photo by Liftarn. Source: Wikimedia Commons

Over the next two decades, other inventors in Europe, most notably Nicolaus Otto, Gottlieb Daimler, Wilhelm Maybach and Karl Benz, followed with their own versions, and in 1892, Rudolf Diesel developed the first compression ignition engine that is today known by his name – the Diesel engine. Together the rapid developments of the closing decades of the 19th century resulted in the evolution of the IC engine into two major types – the two-stroke and four-stroke piston engines, though there were other variants like the six-stroke piston engine and the Wankel rotary engine. These are all intermittent combustion engines with the spark occurring at a specific point of the rotary cycle. Another category of IC engines also evolved during this period – the continuous combustion engines like gas turbines and jet engines.

Based on the use of fuel, there are two kinds of internal combustion engines in use – the petrol or gasoline engine, also called the spark ignition engine, and the diesel engine which works on compression ignition (CI) principle. Most of these are four-stroke cycle engines, meaning four piston strokes are needed to complete a cycle, one of which is the power stroke. The cycle includes four distinct processes: intake, compression, combustion and power stroke, and exhaust. Together, these engines power mobility – most commonly used for automobiles including two-and three-wheelers and commercial vehicles. Continuous combustion engines are used to power ships and aircraft.

Besides mobile applications, stationary engines like gas engines or diesel generators are used for backup or for providing electrical power to areas not connected to an electric grid. Smaller engines are commonly used for lawnmowers, string trimmers, chain saws, leaf blowers, pressure washers, jet skis, outboard motors, etc. Along the evolutionary route, all these engines have also improved in size and efficiency. What were once noisy, smelly and leaky fuel guzzling and highly polluting contraptions prone to misfiring and failure gradually metamorphosed into compact units, much less noisy and clean with effective seals that prevent any kind of leaks. These are also highly fuel efficient and low on harmful emissions.

The 1999 Peugeot 206 with a 1.1 L TU1JP petrol engine. Image source: Zirguezi

The oil crisis and quest for fuel efficiency

The Ford Model T ushered in not only the automobile revolution, but also sowed the seeds for industrial automation in the US, which was promptly replicated in Europe, before spreading to the rest of the world. The invention of the wheel at the beginning of civilisation is considered the single most important development in human history and there is a wheel in some form or other in almost every machine developed since.

The wheels of the automobile unleashed a revolution on American roads as the US became the first country in the world to develop a mass market for automobiles and also the automated production processes to manufacture them. It led to the rise of the Big Three automakers and rapid urbanisation and development of country wide road infrastructure that in turn led to more urbanisation and development. A host of businesses and services – fuel stations, dealerships, service centres and independent garages and workshops – flourished, leading to more enterprises and prosperity. These developments were mirrored in Europe and later in the countries of the Asia Pacific. The Gulf oil boom in the 1970s created another huge market for automobiles in the Middle East and gradually, it spread across the world.

The Great Depression of the 1930s and World War II that followed cast a long shadow, but the post war prosperity of the US led to cars becoming bigger in size, with bigger engines to power them. This situation continued till the first Oil Shock of 1973. The earlier attempts by the oil producing Gulf nations with embargoes in the aftermath of the 1967 Arab-Israeli war had failed to make any significant impact on global oil supplies. But the idea of ‘Oil as a Weapon’ stayed and came into force during the 1973 crisis triggered by yet another Arab-Israeli war that took place in October 1973.

Though targeted at the countries that supported Israel, by the time the embargo ended months later in March 1974, oil prices had risen by 300%, from USD 3 to USD 12 per barrel. The effect was felt by consumers globally in general, the automobile segment in particular. Used so far to bigger cars regardless of class, American preferences changed to smaller cars severely impacting the fortunes of the Big Three as consumers turned their attention to the smaller, fuel efficient Japanese cars that had entered the US market. These cars increasingly gained in popularity as they were also much cleaner with demonstrable reductions in harmful emissions released to the atmosphere.

The second oil shock that followed in 1979 triggered by the crisis in Iran, and later exacerbated by the prolonged war with Iraq, further impacted the development of automobiles with consumers demanding fuel efficient cars, this time also due to the rising environmental consciousness and the need for clean air. The IC engines were now coming under scrutiny for possible improvements in terms of increased efficiency and reduced emissions. But even before these concerns became prominent, researchers were working to improve the fuel efficiency of IC engines and reduce operating costs. The idea was to ensure the optimal use of finite fuel resources and also reduce emissions of pollutants such as nitrogen oxides (NOx) and particulate matter (PM).

These efforts were successful in reducing emissions by more than 99% to comply with regulatory standards. The process of achieving higher fuel efficiency in IC engines is a complex one using a combination of fuel injection methods, compression pressure and treatment of exhaust emissions with catalytic converters. It also involves use of electronics and software code to achieve the delicate balance between vehicle performance and fuel efficiency. The use of software left room for manipulation and the subsequent developments including the various emission scandals, most notably the one involving Volkswagen diesel engines, cast doubts over the entire efficiency norms being open to manipulation.

Thomas Schäfer, CEO Volkswagen Brand, and EV concept ID. 2all. Image source: Volkswagen

The EV makes a comeback

According to the US Department of Energy, Office of Scientific and Technical Information (OSTI) website, IC engines operating on fossil fuel oil provide about 25% of the world’s power, and in doing so, they produce about 10% of the world’s greenhouse gas emissions. As per two decades of ground-breaking peer-reviewed papers published in the International Journal of Engine Research, today’s IC engines are a technological marvel. However, the emissions scandals referred to in the preceding paragraph have cast doubts on technology to make further contributions to the reduction of transportation sector emissions. The clamour for proposals to replace vehicle IC engines with electric-drives had gained momentum.

At the heart of the debate about automobiles powered by IC engines versus electric vehicles is the mandate for Net Zero emissions by 2050. The Paris Agreement signed by 196 countries in December 2015 sets out a number of climate change targets, one of which is to meet a 1.5-2°C limit in global warming. It also stipulates that global carbon emissions should reach ‘net zero’ before 2050.

The European Union, for example, has proposed ‘Fit for 55’, a climate law that makes reaching the EU’s climate goal of reducing EU emissions by at least 55% by 2030 a legal obligation. EU countries are working on new legislation to achieve this goal and make the EU climate-neutral by 2050. According to Power2Drive Europe, which is part of ‘The Smarter E Europe’ – the continent’s largest platform for the energy industry, this means all new cars or vans sold in the EU from 2035, whether manufactured locally or imported, must be zero-emission vehicles. Automobile manufacturers on their part are gearing to meet this challenge.

The Tesla supercharger network. Image source: Tesla

Stung by the diesel emissions scandal of 2015 that forced it to pay more than Euro 27 billion in penalties, Volkswagen had announced in 2018 that it will develop its final generation of vehicles using combustion engine technology in 2026. The Volkswagen Group with 10 major brands is one of the largest automobile manufacturers and has announced New Auto as the group strategy for sustainable mobility in future with a strategy shift toward battery-driven vehicles. The group plans to evolve from an international automotive company into a software-centric global leader in sustainable mobility by 2030 and views autonomous driving as one of the new core competencies. In order to beat the price barrier, Volkswagen recently unveiled the ‘ID. 2all’ concept car with a starting price of less than 25,000 euros. The car is due for commercial launch in 2025.

Other European automakers have followed suit. Mercedes had announced in 2021 that any new vehicle architecture it releases from 2025 onwards will be exclusively electric. BMW too has electric vehicles available across all its platforms and plans 50% all-electric production by 2030. It is on course for the zero emissions vehicles by 2035. Italian automaker Fiat has already announced that it will go all-electric by 2030, making Fiat an exclusively EV brand.

French company Renault, already a major producer of EVs, also aims to become an all-electric car brand in Europe by 2030. This applies not only to the Renault brand, but to Groupe Renault – including brands such as Alpine and Dacia. Even Toyota, a pioneer in hybrid technology but with no electric model in Europe so far, has announced that it will be ready for 100% EVs in the EU by 2035! For the record, EVs have accounted for more than 13 percent of Europe's car sales so far in 2023, according to a report in Euronews. Electric car sales are rising fast and battery-powered vehicles now account for more than 13.4 per cent of new car sales across Europe, according to figures from the first quarter of this year.

Across the Atlantic in the US, EV sales are slower despite Tesla making news regularly with its sales figures. With over 250 million cars on its roads including SUVs and light trucks, EVs account for only 1% of the total. According to a consumer trends report by global data analytics and credit reporting company Experian, new electric vehicle registrations in the US are on the increase. Back in 2018, they comprised just 1.5% of total new vehicle registrations. By 2022, they had risen to over 5%.

This is an increase of 250%. While Tesla is the market leader, Hyundai along with Kia is a distant second, with Ford, GM and others making up the rest. According to the S&P Global Mobility forecasts, electric vehicle sales in the United States could reach 40 percent of total passenger car sales by 2030, and more optimistic projections foresee electric vehicle sales surpassing 50 percent by 2030. The Biden administration through an Executive Order issued in 2019 talks about setting a goal that 50 percent of all new passenger cars and light trucks sold in 2030 be zero-emission vehicles, including battery electric, plug-in hybrid electric, or fuel cell electric vehicles. But so far only California and a few other States have announced future bans on IC engine powered cars.

Yet, with both Ford and GM ramping up production of EVs, the numbers are only going to increase in years to come. Ford has recently received a $9.2 billion loan from the US Department of Energy’s (DOE) Loan Programs Office (LPO) for the construction of three manufacturing plants that will produce batteries in collaboration with cell maker SK Innovation for electric vehicles built under the Ford and Lincoln brands. This follows the $2.5 billion loan received by rival GM last year, for a battery manufacturing joint venture with LG Energy Solution to set up three new lithium-ion battery cell manufacturing facilities in the United States.

In addition, both Ford and GM have recently signed agreements with Tesla to share the EV charging infrastructure in North America. The access to Tesla’s 12000+ superchargers to its own 10,000+ fast chargers under the BlueOval network provides significant advantage to Ford as it is ramping up production of the popular Mustang Mach-E and F-150 Lightning, and preparing to launch a series of next-generation EVs starting in 2025. For GM, the addition of Tesla superchargers to the more than 134,000 chargers available to GM EV drivers is a key part of its EV expansion strategy.

Ford BlueOval City, the complex meant for battery-producing facilities. Image source: Ford Motors

Is the combustion engine doomed?

So with so much happening on the EV front, is the IC engine doomed? Highly unlikely, indicate informed sources.

Those supporting the case for IC engines – and it is not just the automobile industry alone – are not convinced this is the end of the workhorse that has served the industry so well. Even with the re-emergence of the EV as a serious contender for mobility at the turn of the century, development efforts to further improve the performance and reduce emissions have continued unabated.

In a 2019 editorial in the International Journal of Engine Research (IJER) on ‘The future of the internal combustion engine’, the authors point out several flaws in the assumptions and arguments used against the IC engines. They argue that the debate is not a fair one and loaded in favour of the EV in face of several facts that are simply not in keeping with the reality as it exists today. The gist of its arguments may be captured in the following points:

- Advancements in IC engine technology have brought pollutant levels down a 1000-fold in past decades, which now make particulate emissions from tyre and brake wear a larger problem than engine emissions (in both IC engine powered and electric vehicles);

- Many believe that most of the world’s GHG emissions come from cars and trucks, a misconception that is grossly incorrect, as they produce only about 10% of the world’s greenhouse gas emissions;

- There are around 380 million heavy-duty vehicles in the world and it is clear that ‘zero emissions’ BEVs will not replace IC engines in these to any significant degree because of the weight, size and cost of the batteries required; and

- The electricity that is used for charging EVs is still generated from non renewable energy sources with only a minuscule percentage coming from renewable sources. The BP review of World Energy forecasts that the fraction of total energy production from renewables will only reach about 14% by 2040.

Similarly, the eFuel Alliance, an interest group committed to promoting the political and social acceptance of eFuels and to securing their regulatory approval, is lobbying for fair competition and a level-playing field for all relevant emission reduction solutions. eFuels are synthetically produced liquid fuels based on hydrogen and CO2. By using CO2 from the atmosphere and renewable energies, eFuels can be produced in a climate-neutral manner. The eFuel Alliance maintains it is committed to the EU's 2050 climate protection targets and wants to actively support the transition to sustainable, modern and competitive economies in the EU. According to the eFuel Alliance, eFuels are the global solution to a global challenge – because with eFuels vehicles and plants can be used climate-neutrally worldwide today and in the future. But eFuels are still a work in progress with lack of regulatory approvals and industrial scale production, though pilots have established the feasibility. According to informed sources, even the European Commission has said it would carve out an exemption for the continued sale of cars that run on e-fuels past 2035 at the request of some member countries.

In the meanwhile there are a few major challenges on the road to electrification of mobility which may be summed up as:

- The high initial cost of the EV which is beyond the average customer even with various government incentives

- The limited and inadequate charging infrastructure even though subsidised by the government, and

- The high cost of battery replacement and the fact that the battery supply chain is largely controlled by China and open to manipulation.

Bosch is encouraging the use of renewable and synthetic R33 Blue Diesel, an approved fuel made by Shell. Image source: Bosch

Conclusion

In view of the facts as elaborated in this article, it is more than likely that future mobility will be characterised by a mix of solutions rather than any single panacea. While EVs are certainly back with a lot of promise and government support across the world in quest of sustainability, the ground realities cannot be ignored. The replacement of the estimated 1.2 billion light duty vehicles plying across the road with affordable EVs will take several decades. The solution, as pointed out in the IJER editorial, is in having various options to choose from during the intervening years. These options include battery electric and hybrid electric vehicles (BEV and HEV), fuel cell electric vehicles (FCEVs) and conventional vehicles. This will provide consumers a good choice based on affordability as well as specific applications in terms of passenger or freight carriers, transport, etc.

References

1. https://www.energy.gov/articles/history-electric-car

2. https://thewonderofscience.com/phenomenon/2018/7/12/fire-piston

3. https://en.wikipedia.org/wiki/History_of_the_internal_combustion_engine

4. https://en.wikipedia.org/wiki/Volkswagen_emissions_scandal

5. https://www.un.org/en/climatechange/paris-agreement

6. https://www.whitehouse.gov/briefing-room/presidential-actions/2021/08/05/executive-order-on-strengthening-american-leadership-in-clean-cars-and-trucks/

7. https://www.researchgate.net/publication/336018267_IJER_editorial_The_future_of_the_internal_combustion_engine

8. https://www.efuel-alliance.eu/efuels/what-are-efuels