www.magazine-industry-usa.com

25

'25

Written on Modified on

AI Vision Advances Automated Part Sorting

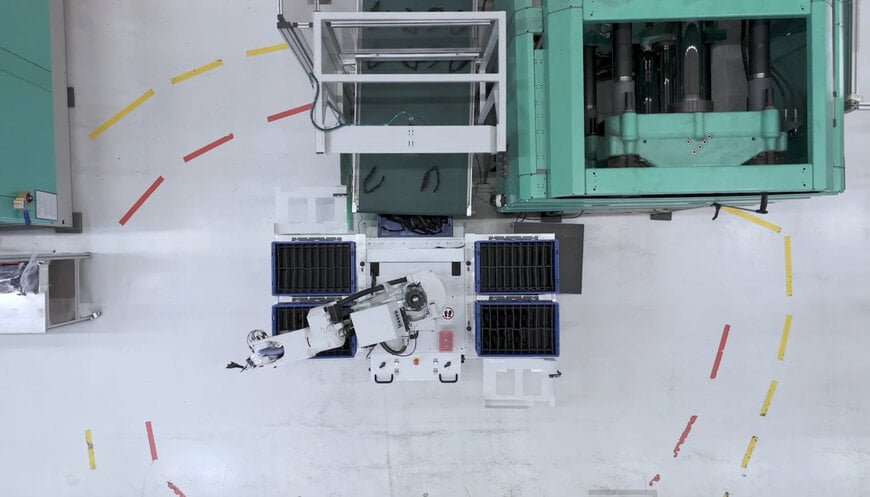

Yaskawa robotics and FMB’s modular handling platform use AI-enabled machine vision to identify, orient and sort complex injection-molded parts directly from the conveyor belt.

www.yaskawa.eu.com

Automated handling and quality control are increasingly important in injection-molding, where parts differ in geometry, orientation and handedness, and where downstream tasks require reliable sorting into designated KLT containers. In this context, FMB has integrated an AI-driven vision solution and an industrial robot to automate what has traditionally been a manual, high-attention operation.

Recognising Complex Workpieces on the Conveyor Belt

Injection-molded parts leaving the conveyor belt often appear in random positions and include both left- and right-hand variants. These factors historically required a skilled operator to distinguish components and place them into the correct KLT containers. The main technical challenge—accurate part recognition under non-oriented conditions—aligns with known constraints in machine-vision-based automation.

FMB addressed this using Keyence’s all-in-one AI camera, validated internally through prior projects involving randomly stored components and bin-picking applications. The camera captures component position and orientation, identifies whether each piece is right- or left-handed, and transmits this information to the robot. AI-supported checks for text, colour, codes or potential production defects add further utility. These functions are consistent with the capabilities of modern industrial vision systems equipped with integrated inference engines.

Robotic Handling for Reliable Sorting

For mechanical handling, FMB uses a Yaskawa GP12 robot, a six-axis model with a 12-kg payload and 1440-mm reach—both appropriate for mid-weight part manipulation in injection-molding environments. After receiving position and orientation data from the vision system, the robot places components into the corresponding KLT containers. The longstanding integration relationship between FMB and Yaskawa reflects industrial practice, where established robot platforms are preferred for repeatable, multi-cycle material-handling tasks.

A Modular Automation Platform for Flexible Use

The handling solution is built on the modular FMB base system. A standardized core module houses the robot, while interchangeable grippers and expansion modules support different processes. This modularity allows the same base system to be reconfigured for new component types or future orders, and the roller-mounted design enables relocation between stations. The “container feed” module stores KLT containers directly at the handling cell, while a double gripper picks up two parts at once. When parts require suction-based handling, the gripper can be swapped quickly using a changeover mechanism. These design choices align with established engineering principles for scalable, multi-purpose automation systems.

Safe and Collaborative Operation Without Physical Barriers

FMB’s system is equipped with a contactless protective setup based on radar scanners. Instead of physical fences, two virtual zones manage human proximity: when the outer zone is entered, the robot slows down; when the inner zone is breached, the robot stops immediately. Once the area is clear, the system resumes operation automatically. This behaviour is consistent with certified safety-rated monitoring technologies used for human–robot collaboration, enabling operators to check container fill levels or replace containers without interrupting the process. As a result, staff previously dedicated to manual sorting can focus on logistics and process supervision.

Supporting Workforce Efficiency Through Automation

Rather than eliminating roles, the automation frees skilled workers from repetitive sorting tasks, allowing them to manage broader production activities. The system’s automated safety concept reduces the need for complex operator training, ensuring that manual interventions remain simple, intuitive, and non-disruptive.

www.yaskawa.com