www.magazine-industry-usa.com

18

'22

Written on Modified on

Fanuc News

FANUC CANADA DEMONSTRATES A WIDE RANGE OF AUTOMATION SOLUTIONS AT FABTECH CANADA

FANUC Canada will demonstrate a variety of automation solutions for the metal forming and fabricating industries at FABTECH Canada.

Image : workplace material handling & safety

FANUC Canada, the leading supplier of CNCs, robotics, and ROBOMACHINEs will demonstrate a variety of automation solutions for the metal forming and fabricating industries at FABTECH Canada. See us June 14-16 at the Toronto Congress Centre in booth #9019.

CRX Collaborative Robots: Easy to Use and Flexible

FANUC recently expanded its popular series of CRX collaborative robots with the new CRX-5iA, CRX-20iA/L and CRX-25iA. The new CRX cobots complement FANUC’s existing line of CR and CRX cobots that now total 11 model variations able to handle products from 4 to 35kg.

Designed for companies looking to increase their capabilities and overcome labor issues, FANUC’s CRX cobots are extremely robust and able to run for up to eight years without maintenance. In addition, interactive programming enables users to teach points using hand guidance or a tablet interface with drag and drop icons.

FANUC’s line of CRX cobots are very easy-to-use, reliable, and offer the flexibility to perform a variety of jobs including inspection, machine load/unload, packing, palletizing, sanding, welding, and many more. The CRX cobots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the CRX to work safely alongside people without the need for expensive guarding.

The CRX series supports several of FANUC’s advanced features including iRVision®, and is a perfect fit for any company looking to achieve higher efficiencies – even those that have yet to use their first robot.

Cobot Demonstrations

FANUC Canada will demonstrate a wide range of collaborative robot applications including:

Adaptive Arc Welding: A collaborative robot system will demonstrate how to help welding customers address gap conditions. First, an operator loads coupons and sets variable gaps of 0-1.5mm between the work pieces. Next, a CR-15iA collaborative robot uses FANUC’s Seam Tracking software with SERVO ROBOT’s FUJI-CAM 2.0 sensor to communicate the gap conditions to the robot, which then performs adaptive welding. The adaptive process has the ability to change weaving amplitude, weave frequency, travel speed, wire feed speed, trim, as well as positional bias in X,Y,Z directions.

The demonstration also features the Lincoln Electric Power Wave® R450 robotic power source with the Advanced Module using the GMAW Pulse process.

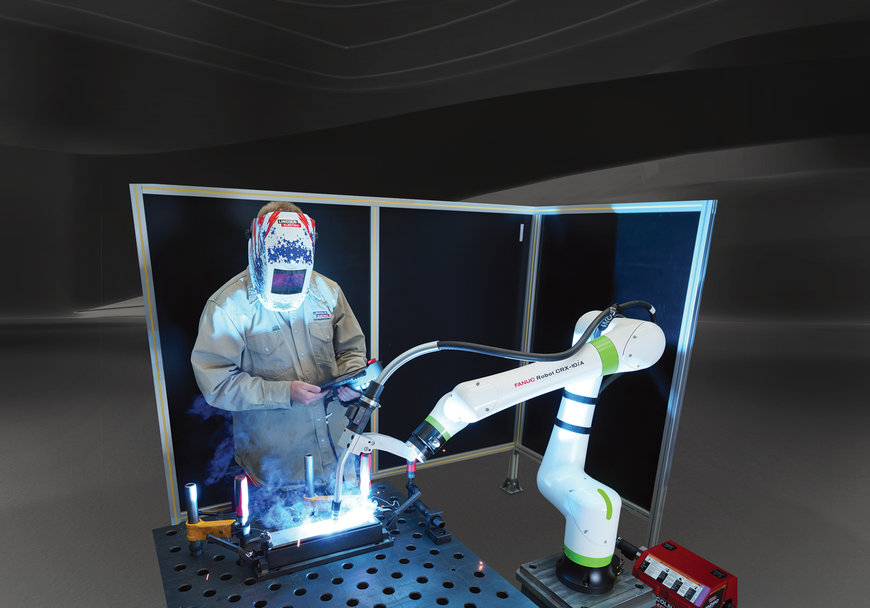

In addition, a new CRX-5iA cobot, offering a 5kg payload will demonstrate gear assembly, a CRX-10iA cobot will showcase collaborative welding, and a CR-35iA cobot will demonstrate metal frame assembly.

Factory Automation Demonstration

FANUC’s Factory Automation division will demonstrate Visual Twin at FABTECH Canada. The Visual Twin demonstration offers an exciting new way to see part production while highlighting FANUC’s end-to-end digitalization solutions for the machine shop.

FANUC’s Visual Twin is an exact software replica of real CNC machine tools. The Visual Twin will display a virtualized 5-axis machine tool cutting a part, which mirrors the real-world machine’s behavior.

www.fanuc.com

FANUC Canada, the leading supplier of CNCs, robotics, and ROBOMACHINEs will demonstrate a variety of automation solutions for the metal forming and fabricating industries at FABTECH Canada. See us June 14-16 at the Toronto Congress Centre in booth #9019.

CRX Collaborative Robots: Easy to Use and Flexible

FANUC recently expanded its popular series of CRX collaborative robots with the new CRX-5iA, CRX-20iA/L and CRX-25iA. The new CRX cobots complement FANUC’s existing line of CR and CRX cobots that now total 11 model variations able to handle products from 4 to 35kg.

Designed for companies looking to increase their capabilities and overcome labor issues, FANUC’s CRX cobots are extremely robust and able to run for up to eight years without maintenance. In addition, interactive programming enables users to teach points using hand guidance or a tablet interface with drag and drop icons.

FANUC’s line of CRX cobots are very easy-to-use, reliable, and offer the flexibility to perform a variety of jobs including inspection, machine load/unload, packing, palletizing, sanding, welding, and many more. The CRX cobots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the CRX to work safely alongside people without the need for expensive guarding.

The CRX series supports several of FANUC’s advanced features including iRVision®, and is a perfect fit for any company looking to achieve higher efficiencies – even those that have yet to use their first robot.

Cobot Demonstrations

FANUC Canada will demonstrate a wide range of collaborative robot applications including:

Adaptive Arc Welding: A collaborative robot system will demonstrate how to help welding customers address gap conditions. First, an operator loads coupons and sets variable gaps of 0-1.5mm between the work pieces. Next, a CR-15iA collaborative robot uses FANUC’s Seam Tracking software with SERVO ROBOT’s FUJI-CAM 2.0 sensor to communicate the gap conditions to the robot, which then performs adaptive welding. The adaptive process has the ability to change weaving amplitude, weave frequency, travel speed, wire feed speed, trim, as well as positional bias in X,Y,Z directions.

The demonstration also features the Lincoln Electric Power Wave® R450 robotic power source with the Advanced Module using the GMAW Pulse process.

In addition, a new CRX-5iA cobot, offering a 5kg payload will demonstrate gear assembly, a CRX-10iA cobot will showcase collaborative welding, and a CR-35iA cobot will demonstrate metal frame assembly.

Factory Automation Demonstration

FANUC’s Factory Automation division will demonstrate Visual Twin at FABTECH Canada. The Visual Twin demonstration offers an exciting new way to see part production while highlighting FANUC’s end-to-end digitalization solutions for the machine shop.

FANUC’s Visual Twin is an exact software replica of real CNC machine tools. The Visual Twin will display a virtualized 5-axis machine tool cutting a part, which mirrors the real-world machine’s behavior.

www.fanuc.com