www.magazine-industry-usa.com

12

'24

Written on

Modified on

Fanuc News

FANUC AMERICA AT AUTOMATE 2024

FANUC America is set to unveil its latest lineup of robots, cobots, software, AI, and motion control innovations at Automate 2024 (May 6-9) in Chicago.

“We’re excited to demonstrate our cutting-edge automation solutions at Automate," said Lou Finazzo, Vice President, FANUC America. “Whether you’re a start-up or a large-scale manufacturer, FANUC offers the world’s most reliable and cost-efficient automation solutions. We are committed to helping our customers achieve their production goals, enhance productivity, and overcome labor constraints.”

CRX 30KG Cobot Demonstrations - Attendees will get a chance to experience FANUC’s wide range of CRX cobots and learn first-hand how easy it is to program a CRX – even a 30kg model - using hand guidance or the intuitive Tablet TP.

Collaborative Palletizing - A CRX-25iA food-grade cobot featuring a 30kg payload and 1,889mm reach, will demonstrate collaborative palletizing. The CRX picks boxes from an infeed conveyor and places to two pallets – stacking the boxes to nearly 8’ high. The robot then depalletizes the boxes back to the infeed conveyor, using its integrated force-sensing capabilities to ensure accurate placement.

The new food-grade CRX-25iA cobot offers a robust construction, corrosion resistance, ease of cleaning, and compliance with food safety regulations to provide a reliable and efficient solution for food companies. Designed to operate safely in food processing facilities, the CRX-25iA’s white epoxy coating meets the USDA Incidental Food Contact Requirements. In addition, it has an IP67 washdown rating, and uses NSF H1 food-grade lubricant.

The demonstration features the new PalletTool® 3, which enables operators to create and modify unit loads directly from the Tablet TP with FANUC’s PalletTool Turbo software using the newly updated user interface via PalletTool 3. This new software package unlocks the ability to modify systems quickly and easily on the floor without needing a PC.

Kitting - A CRX-10iA Food-Grade option cobot will demonstrate packing meat and cheese gift boxes. Attendees are invited to try the cobot’s intuitive hand guidance and easy-to-use Tablet TP.

Arc Welding - Lincoln Electric’s mobile welding cart featuring FANUC’s CRX-10iA offers attendees a hands-on programming experience. The CRX welding cobot is easy to program and use with the intuitive FANUC Tablet TP and the ability to teach torch movements by hand. Lincoln Electric’s Power Wave R450 robotic welding platform provides the same industry-leading performance found in traditional robotic welding.

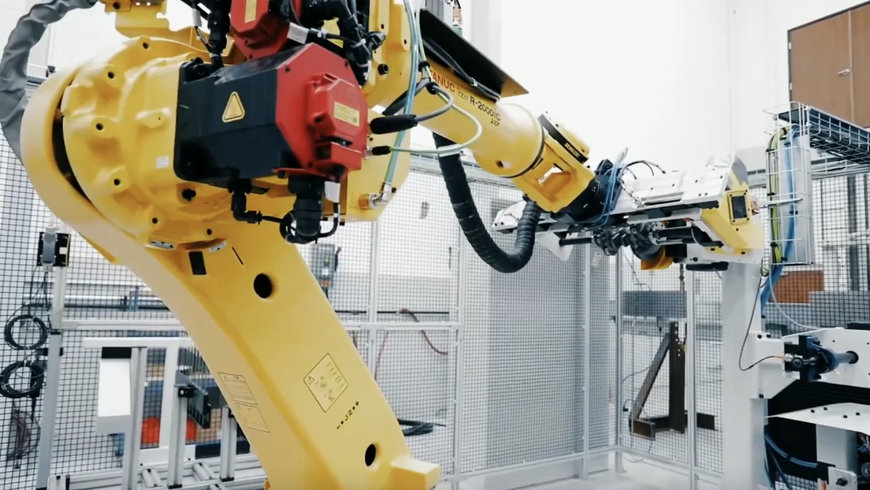

Spot Welding – A CRX-20iA/L uses iRVision® 3DV to locate and pick parts of different sizes from bins and place them onto a turntable. The table rotates the parts to a FANUC R-2000iD/210FH robot equipped with a Servo Gun. The R-2000 robot simulates spot welding the parts together, and then parts rotate back to the CRX to unload and return them to the bins. The demonstration highlights how cobots can be used to assist industrial robots with simple and repetitive tasks.

Gear Assembly - The CRX-5iA cobot, featuring a 5kg payload and 994mm reach will pick and assemble small gears using integrated force control.

Vertical Put Wall - FANUC’s Power Motion i Model A Plus (PMi-AP) will move a tool to random or user-specified locations on a put wall. Attendees can choose which bins to get items from and then the tool pulls the sequence of bins from the put wall and moves them to a conveyor belt for the CRX to access the bin. When a wall bin arrives at the access point, a FANUC CRX-10iA will pick an item and place it in an order fulfillment bin. An order is fulfilled once an item has been picked from each selected wall bin. Once an order has been fulfilled, the put wall system will bring the bins back to the CRX access point. The CRX then picks items from the order fulfillment bin and places them back into the appropriate put wall bins until each one has been restocked. Automated put walls are easy to deploy and scale, helping warehouses and distribution centers improve productivity by increasing order fulfillment, and decreasing labor costs.

The PMi-AP, which offers CNC-style motion control for automated assembly and other applications, integrates seamlessly into virtually any production system using ethernet connection for easy communication between robots and machines. Users who trust FANUC’s reliable control and servo technology along with overall support for machine tools, can expect the same performance and value in general-purpose motion control.

Automated Palletizing/Depalletizing with FANUC M-710iD/50M

The new FANUC M-710iD/50M, combined with two iRVision 3DV/1600 vision sensors and the FANUC iPC, will use the iPC’s AI Box Detection software to locate boxes within stock carts. Once located, the M-710iD/50M will depalletize boxes from one cart and utilize PalletTool to palletize them on the opposite cart. Once a cart is empty, the process will be repeated by depalletizing and palletizing back to the original stock cart. The tall stock carts highlight the advantage provided by the M-710iD/50M’s curved arm.

FANUC’s AI-driven iPC enables high-performance advanced picking in challenging lighting conditions to ensure seamless, reliable depalletizing. iPC is a major benefit for this demonstration because the boxes have patterns that are difficult to segment and determine edge locations.

FANUC SCARA Solutions

FANUC recently expanded its line of four-axis SCARA robots to include the SR-3iA/U ceiling mount featuring a full 360-degree work envelope with no dead zones, the robot can access any point within its reach. In addition, FANUC’s SCARA lineup also includes the SR-3iA/C and SR-6iA/C cleanroom variants.

High-Speed Tracking - The SR-3iA/U ceiling mount SCARA robot has a 3kg payload and 350 mm reach. The SR-3iA/U will use iRVision 3DV and iRPickTool to pick various parts from a moving circular conveyor, move them to a 2D camera for inspection, then place them onto an outfeed conveyor into the appropriate Pass/Fail locations.

Packing Medical Vials - A FANUC SR-12iA robot with the Environmental Option will pack and unpack trays of medical vials into a bin, and then pick up and transfer a full bin to demonstrate the SR-12iA’s payload capability. The SR-12iA robot with the Environmental Option includes white epoxy coating, bellow covers, anti-rust bolts and seals, and an IP65 rating to withstand dust and liquids.

Cheeseburger Assembly - An LR Mate 200iD/7LC and SR-6iA/C – both cleanroom robots - will assemble cheeseburgers. First, the LR Mate 200iD/7LC uses iRVision 3D to pick and place four hamburger buns on one of two slides. The SR-6iA/C SCARA robot will then pick and place a hamburger patty and a piece of cheese on top of each bun. The LR Mate completes the cheeseburgers by placing a tomato slice and a top bun (the robots alternate between placing items on each slide). Once all four cheeseburgers are completed, the robots remove items in reverse order and the cycle repeats.

The popular LR Mate 200iD series of tabletop industrial robots offers a “best in class” work envelope for both upright and invert mount installations. Ten models include clean room and wash-proof versions, each with various wrist speeds and reaches to accommodate even the most limited workspace. The LR Mate series, introduced over 30 years ago, is one of FANUC’s most popular robot models with more than 70,000 units installed globally.

The SR-6Ai/C SCARA has a 6kg payload and 650 mm reach. It features a white epoxy coating and is rated IP54, meaning it is protected against contamination from limited amounts of dust and other particles as well as water spray. The SR-6iA/C can meet ISO Class 2 to ISO Class 5 for cleanroom operation and uses NSF-H1 food-grade grease and anti-rust bolts for food handling applications.

Visual Line Tracking – A FANUC LR Mate uses an overhead-mounted 3DV/400 iRVision Sensor and Line Tracking with iRPickTool to find and track candy moving down a conveyor. The robot picks apart and places it into a bin. The system highlights the speed and accuracy of the 3DV/400 vision sensor and the ability to detect the 3D orientation of a workpiece on a noisy background.

FANUC MT-Linki Optimizes Shop Floor Connectivity

For machine shops looking to take advantage of IoT data, MT-Link i provides real-time equipment status and conditions info as well as other important production and maintenance data. Since MT-LINKi can monitor various sensors connected to machine tools, it is a simple way to bring a facility into the IIoT universe.

Built-in Intelligence

FANUC offers application software for packaging and palletizing, integrated iRVision® and tracking features, ROBOGUIDE simulation, Dual Check Safety (DCS), and Zero Down Time (ZDT) to help customers monitor and manage their automation.

Learn from FANUC’s subject matter experts at Automate in the following conference sessions. For more information visit Automate’s Conference Agenda Page.

www.fanucamerica.com