Bonfiglioli Showcases Advanced Mechatronic Solutions at EuroBLECH 2024

Bonfiglioli showcases six customized metalworking solutions at EuroBLECH, combining precision gearboxes, motors, and inverters for efficient, customizable systems for sheet metal processing, handling, and storage.

At EuroBLECH, the world-leading vertical trade dedicated to the entire sheet metal working technology, taking place in Hanover from the 22nd to the 25th of October, Bonfiglioli will show all its know-how in developing complete solutions, combining both industrial and precision gearboxes with motors and servomotors up to IE5, and with frequency inverters. Such products are often co-designed with the key players of this industry and targeted to light, medium and heavy duty applications.

At EuroBLECH six product packages will be displayed, all of them are intended for companies which shape, form process and handle sheet metal.

Six high-quality solutions for six different applications

The first package developed for roller tables can be used for handling all kind of ferrous and non-ferrous products during the transformation process or the stocking phase. It combines a planetary gearbox of the 300 Series, featuring a high overload capacity and offering torque control, a synchronous reluctance motor of the BSR Series integrating a highly accurate sensorless control technology and an on-board mounted DGM decentralized inverter.

Being the inverter directly supplied with the gearmotor, mechanical assembly, wiring and basic programming are performed by Bonfiglioli, thus reducing installation times, costs and complexity. Moreover, it boasts a high degree of protection (according to IP65) and can therefore withstand harsh and dusty environments within the production line.

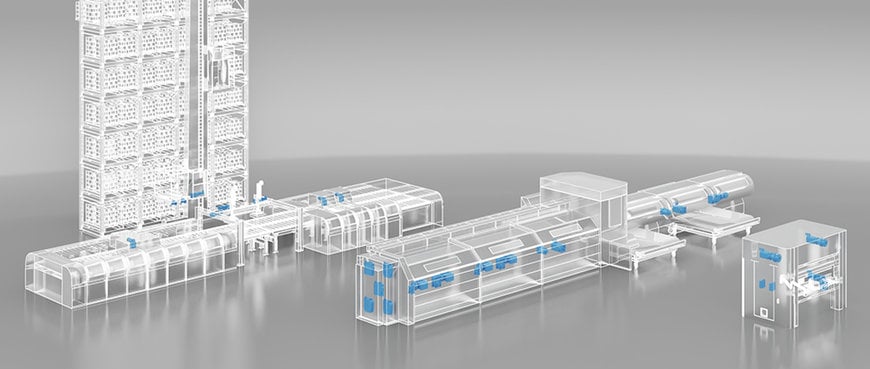

The second solution has been developed for semi-finished sheet metal handling and storage systems. It consists of a helical bevel gearmotor of the A Series, offering compactness when combined with a permanent magnet synchronous motor of the BMD Series, marked by low inertia and compliant with the most stringent requirements in terms of precision, dynamics and speed settings, along with an ANG Active Next Generation servo inverter.

The inverter integrates a micro controller which guarantees enhanced functionalities, such as cycling synchronous positioning mode with cubic interpolation, brake control and evaluation of feedback contact. The solution has been also fitted with Z and W-sensors, namely the IoT sensors that underpin Condition Monitoring and Predictive Maintenance services and provide real-time data about vibrations and temperature.

The third solution for plate bending is included on heavy duty applications and dynamics. It is composed by a planetary gearbox of the 300 Series with hydraulic input configuration that can be adapted to all customer requirements for hydraulic motors. Therefore it reflects Bonfiglioli’s broad range of systems, spanning from electronics to hydraulics, from mechatronics to mechanics.

The fourth application dish ends and flanging machines solution is also requiring heavy duty products due to the process. The displayed product package is composed by a bevel helical gear unit of the HDO Series, ensuring high output torque, robustness reliability and long operating life, and an asynchronous IE3 three phase motor of the BX Series. This combination drives the axis of the machine form high thickness metal plates.

The intralogistics and warehose storage systems solutions are represented by helical parallel-shaft gearmotor of the F Series with BX motor and the closed loop ACU (Active Cube) frequency inverter, efficient, reliable and low-noise effective.

The last purely mechatronic solution features a precision planetary gearbox of the MP Series, combined with brushless BMD servomotor and the new premium frequency inverter AxiaVert offers modularity, wide range of torque and dimensions, high dynamics and safety functionalities. it can namely detect potentially unsafe situations without the need of sensors and related wiring. The solution presented at the booth is ideally applied to laser cutting systems, both for metal tubes and sheets.

Bonfiglioli's participation in EuroBLECH demonstrates the company's broad presence across all sectors related to sheet metal processing, not only forming but also the transportation, handling and storage of plates, as well as its commitment to providing innovative and high-quality products focused on customer needs.

www.bonfiglioli.com