www.magazine-industry-usa.com

23

'25

Written on Modified on

IDS: Micrometer-precise material analysis

High-speed image analysis of the smallest particles in real time.

en.ids-imaging.com

Precise material analysis plays a central role in many industries - from the pharmaceutical and food industries to construction materials, biotechnology and environmental sciences. Whether for quality assurance or for predicting material behavior, the precise characterization of particles is crucial. Development laboratories, materials research institutes and testing facilities are confronted with a variety of challenges: Particles can vary widely in form and origin - be it powder, liquid, tablet, sand, microplastic or pigment. In order to analyze this diversity, laboratories must master a balancing act between precision, efficiency and practical requirements. Accuracy and reproducibility are particularly important, as even the smallest deviations in particle size distribution - often in the micro or nanometer range - can have a significant impact on material properties. At the same time, the high throughput in production environments requires rapid analysis of numerous samples without compromising on measurement quality.

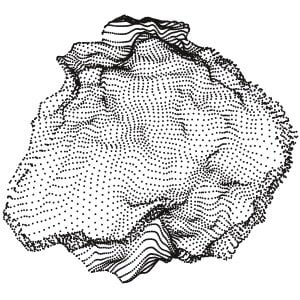

Representative samples of dry powder before measurement

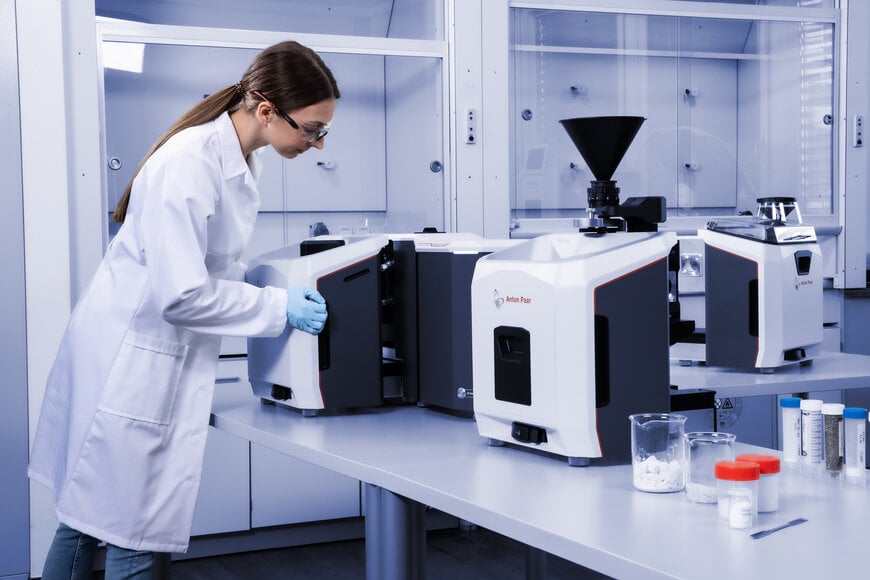

This is where dynamic image analysis (DIA) comes in. This innovative technology makes it possible to record a large number of parameters for determining particle size and shape in real time. "Dynamic image analysis has proven itself as a viable R&D and quality control method in various industries. Particles are recorded as they flow through a measuring cell using high-speed cameras or other imaging sensors and then analyzed with software support," explains Dr Christian Moitzi, Research & Development at Anton Paar GmbH. The Austrian company specializes in particle characterization. The devices developed by the company for this purpose are designed to capture high-speed images of moving particles. One of the most important components in their successful dynamic image analyzers is a uEye Warp10 high-speed camera from IDS Imaging Development Systems GmbH in addition to the sample chamber and lighting system.

Dynamic image analyzer Litesizer DIA 700

"With the Litesizer DIA series, the size and shape of particles can be characterized easily and reliably by directly analyzing the particle images. The most powerful device in the series, the Litesizer DIA 700, can measure particle sizes from 0.5 micrometers to 16 millimeters," emphasizes Dr Moitzi. Thousands or even millions of particles can be visualized in a matter of seconds during a measurement. Thanks to the high frame rate and fast data transmission, it is possible to image an unrivalled number of particles within a short measuring time and analyze them in real time.

The better particles can be characterized, the better material behavior can be predicted

1 million particles for errors of less than 1 per cent

"It starts with the preparation of a representative sample. This sample can consist of various materials, e.g. powders, granulates, suspensions or even biological preparations such as cells. As a rule, more than one million particles are required to achieve a maximum error of less than one per cent. Samples are fed in using one of three interchangeable dispersion units, which enables both dry powders and dispersions to be measured," says Dr Moitzi.

"It starts with the preparation of a representative sample. This sample can consist of various materials, e.g. powders, granulates, suspensions or even biological preparations such as cells. As a rule, more than one million particles are required to achieve a maximum error of less than one per cent. Samples are fed in using one of three interchangeable dispersion units, which enables both dry powders and dispersions to be measured," says Dr Moitzi.

The Litesizer DIA combines 3 dispersion units in one dynamic image analyzer

The sample is placed in a chamber in which it is continuously moved or dispersed. Various mechanisms such as vibration, air flow or fluid circulation can be used to keep the particles in motion. The particles, which move through the image field at a speed of up to 30 m/s, are illuminated stroboscopically. To avoid motion blur, the illumination pulse is shorter than 100 nanoseconds. The magnification can be adjusted by automatically changing three lenses.

The challenge of high-speed processing

"Large volumes of data have to be processed in real time," says Christian Moitzi, citing an important requirement for the system. The 10GigE Vision high-speed camera integrated with the help of the IDS peak SDK records an image sequence at the required high frame rate and thus enables the observation of fast particle movements.

In addition to the speed, the interface and sensor are decisive for the selection of the camera model. The uEye Warp10 with integrated Sony IMX255 global shutter CMOS sensor delivers everything the demanding task requires: high resolution, high frame rates and noise-free image reproduction. Readout noise and dark current are among the lowest values in the entire sensor market. With its resolution of 5.10 MP (2472 x 2064 px) at 220 fps, the camera is particularly suitable for applications where high speeds are required. The high resolution ensures that even the smallest details are captured.

The challenge of high-speed processing

"Large volumes of data have to be processed in real time," says Christian Moitzi, citing an important requirement for the system. The 10GigE Vision high-speed camera integrated with the help of the IDS peak SDK records an image sequence at the required high frame rate and thus enables the observation of fast particle movements.

In addition to the speed, the interface and sensor are decisive for the selection of the camera model. The uEye Warp10 with integrated Sony IMX255 global shutter CMOS sensor delivers everything the demanding task requires: high resolution, high frame rates and noise-free image reproduction. Readout noise and dark current are among the lowest values in the entire sensor market. With its resolution of 5.10 MP (2472 x 2064 px) at 220 fps, the camera is particularly suitable for applications where high speeds are required. The high resolution ensures that even the smallest details are captured.

Ultra-fast 10GigE Vision industrial camera uEye Warp10

"Compared to 1GigE cameras, the uEye Warp10 achieves up to 10 times the transmission bandwidth. Together with the combination of high resolution and high dynamic range, the GV-7090WP presents itself as an ultra-fast, powerful all-rounder," says Marcus Rembold, Product Owner 2D Cameras at IDS, describing the camera model used. The robust, GenICam-compliant uEye Warp10 camera can forward image information in the Gigabit Ethernet-based network with virtually no delay. It therefore shows its strengths precisely in inspection tasks such as this, where objects need to be recorded and analyzed in full detail and without motion blur.

Sophisticated image analysis algorithms

"The camera images are transferred to the PC, where they are segmented and various size and shape parameters of each individual particle are calculated," says Christian Moitzi, explaining the next steps in image processing. "The heart of DIA lies in the analysis of the captured images. Sophisticated image analysis algorithms and software are used to process the images and extract relevant information about the particles. The user receives, practically in real time, averaged size distribution functions as a result. However, it also has the option of analyzing individual particles and filtering images of particles with special properties from the entirety."

Example building materials industry

The parameters examined provide detailed insights into the properties and behavior of a material sample. These can be bulk material properties such as density, flowability, ballistics and others. Useful information for sectors such as the building materials industry. "The quality of cement depends heavily on the size and shape of its particles, which affect its surface, compressive strength and curing time," says Christian Moitzi. Particles that are too fine cause the end product to set exothermically, while particles that are too large do not hydrate completely. The flowability and water requirement of cement can vary drastically between regular (spherical) and irregular particles. These factors can lead to cracking, shrinkage or porosity and thus severely impair the quality, durability and mechanical properties of the cement.

Outlook

Investing in a dynamic image analysis device such as the Litesizer DIA 700, which is equipped with an ultra-fast, extremely high-resolution 10 GigE industrial camera, pays off in the long term. Thanks to fast image processing and precise analysis in real time, process sequences are optimized and production decisions are made on the basis of better data. More precise particle characterization enables better process control and optimized material usage - for example through more precise dosing and the reduction of faulty batches. The availability of this high-speed camera technology and fast image processing makes dynamic image analysis a particularly attractive, future-proof alternative to traditional methods such as laser diffraction.

Camera

Sophisticated image analysis algorithms

"The camera images are transferred to the PC, where they are segmented and various size and shape parameters of each individual particle are calculated," says Christian Moitzi, explaining the next steps in image processing. "The heart of DIA lies in the analysis of the captured images. Sophisticated image analysis algorithms and software are used to process the images and extract relevant information about the particles. The user receives, practically in real time, averaged size distribution functions as a result. However, it also has the option of analyzing individual particles and filtering images of particles with special properties from the entirety."

Example building materials industry

The parameters examined provide detailed insights into the properties and behavior of a material sample. These can be bulk material properties such as density, flowability, ballistics and others. Useful information for sectors such as the building materials industry. "The quality of cement depends heavily on the size and shape of its particles, which affect its surface, compressive strength and curing time," says Christian Moitzi. Particles that are too fine cause the end product to set exothermically, while particles that are too large do not hydrate completely. The flowability and water requirement of cement can vary drastically between regular (spherical) and irregular particles. These factors can lead to cracking, shrinkage or porosity and thus severely impair the quality, durability and mechanical properties of the cement.

Outlook

Investing in a dynamic image analysis device such as the Litesizer DIA 700, which is equipped with an ultra-fast, extremely high-resolution 10 GigE industrial camera, pays off in the long term. Thanks to fast image processing and precise analysis in real time, process sequences are optimized and production decisions are made on the basis of better data. More precise particle characterization enables better process control and optimized material usage - for example through more precise dosing and the reduction of faulty batches. The availability of this high-speed camera technology and fast image processing makes dynamic image analysis a particularly attractive, future-proof alternative to traditional methods such as laser diffraction.

Camera

uEye Warp10 - ultra-fast, extremely high-resolution 10GigE industrial camera

- Model used: GV-79F0WP-M-GL

- Camera family: uEye Warp10

Client

Anton Paar produces and distributes high-precision laboratory measuring instruments and process measuring systems and offers customized automation and robotics solutions worldwide. The company is the global market leader in the fields of density and concentration measurement, rheometry and CO2 measurement.

Author

Silke von Gemmingen

IDS Imaging Development Systems GmbH

Dimbacher Str. 10

74182 Obersulm

Germany

T: +49 7134 96196-0

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

W: www.ids-imaging.us

Image rights: Anton Paar GmbH, Graz

© 2025 IDS Imaging Development Systems GmbH