www.magazine-industry-usa.com

10

'25

Written on Modified on

IDS: Intelligent, camera-based passenger counting on ferries for more transparency and predictability in local transport

The precise recording of passenger numbers is essential for transport companies - it helps to optimize timetables, make better use of capacities and organize local public transport more efficiently.

en.ids-imaging.com

A modern solution for this is camera-based passenger counting. Intelligent image processing systems automatically and precisely record how many people board and alight - without any manual counting. With Adigo nPax, the Norwegian company Adigo Mechatronics has developed such a system especially for ferries. The required images are supplied by an industrial camera from IDS Imaging Development Systems GmbH. But how exactly does this technology work, what advantages does it offer and where is it already being used?

Application

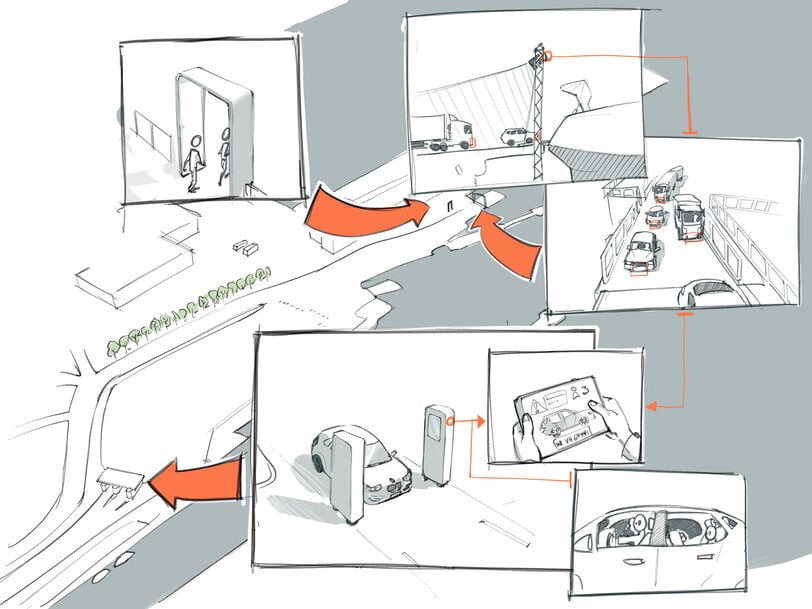

International shipping regulations require ferry operators to know the exact number of passengers on board - a task that has traditionally been handled in conjunction with the ticketing process. However, in the course of automation, ferry boarding has increasingly shifted to free-flow models. Vehicles and passengers can drive or walk directly onto the ferry without traditional ticket controls or barriers. Automated systems such as cameras, sensors or digital toll technologies record the vehicle's license plate number or the amount of passengers in real time. The aim: a fast and smooth boarding process without long waiting times or manual checks.

However, counting passengers in moving vehicles is still a challenge that often requires staff - especially when there are large numbers of passengers or when small children are sitting in vehicles with tinted windows.

This is where the Adigo nPax system comes in: Using a combination of a camera and AI-supported algorithms, it automatically records the number of passengers and transmits it directly to the ship's logging system. The data is documented centrally and thus made available for authorities or internal processes. If necessary, the crew can check the count manually using a mobile device. Every correction helps to continuously improve the system.

Realization of passenger counting with Adigo nPax

More efficiency thanks to precise passenger data

With Adigo nPax, counting accuracy and operational efficiency can be significantly increased. Specially selected industrial cameras with customized lighting solutions reliably capture clear images - even at high vehicle speeds. The data is analyzed directly on site: State-of-the-art AI models process the images in real time and immediately provide exact passenger numbers for every vehicle that passes through the system. In the interests of data security, all image data is used exclusively locally on board. No external storage or transmission takes place - a prerequisite and a decisive contribution to protecting the privacy of passengers.

The system has been in use on the Arsvågen-Mortavika route for over a year. "Control tests with hundreds of vehicles have shown a counting accuracy of over 98 per cent. Despite challenges such as tinted windows, child seat covers and the changeable weather conditions that are typical of the Norwegian coast, Adigo nPax reliably delivers precise results," says André Ødegårdstuen - Product Developer at Adigo Mechatronics.

Adigo nPax immediately delivers exact passenger numbers for every vehicle that passes through the system.

Camera with exceptional light sensitivity

The camera used - a GigE uEye CP - was supplied by IDS. Its compact magnesium housing (29 x 29 x 29 mm) is both light and robust at around 50 g and emphasizes the camera's suitability for industrial use. It is ideal for tasks in the fields of automation, medical technology and life sciences, agriculture, logistics, traffic and transport, for example.

Adigo relies on a particularly powerful model with an e2v 1.3 megapixel CMOS sensor - one of the most sensitive sensors in the IDS portfolio. In addition to the outstanding light sensitivity in CCD quality, it offers two global and rolling shutter variants that can be switched during operation, thus maximizing flexibility for changing requirements and environmental conditions. Furthermore, a maximum of four areas of interest are available. This allows either several characteristics to be checked simultaneously or the AOIs to be captured in an exposure series with different parameters.

“The camera was specifically chosen because it has exceptional sensitivity in the critical wavelength range and delivers high-quality images at the required frame rates,” says Ødegårdstuen. “Seamless integration into the Adigo nPax system was achieved through the IDS peak C++ interface, which enables robust and efficient operation.”

Selected industrial cameras with customized lighting solutions and AI reliably capture all passengers.

Outlook

Interest in automated passenger counting solutions is growing rapidly not only in Adigo's home market of Norway, but also internationally. This is due to the increasing demand for efficient, data-driven solutions to optimize public transport. Automated systems, especially those based on camera technology, not only provide accurate passenger counts, but also valuable insights into traffic flows and enable better resource utilization. At a time when sustainability and efficiency are playing an increasingly important role in the public sector, such technologies are helping to make the transport sector fit for the future.

Camera

uEye CP - incredibly fast, powerful, future-proof

Model used: UI-5240CP Rev.2.2

Camera family: uEye CP